Novel grinding part and automatic grinding device

A component and a new type of technology, applied in the field of new grinding parts and automatic grinding devices, can solve the problems that the temperature of the grinding area cannot be effectively reduced to remove debris, the cooling water cannot effectively reach the grinding area, and the appearance of mobile phone shell products is affected. Large-scale industrial production needs, meeting the needs of industrial production, and reducing the effect of artificial dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

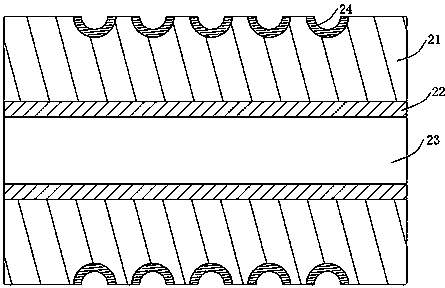

[0027] This embodiment discloses a mobile phone shell grinding wheel component, the grinding wheel component is a cylindrical structure, such as figure 1 As shown, the outer layer of the grinding wheel part is a flexible base material layer 21, the flexible base material layer 21 is provided with an abrasive grain layer 24, and the inner layer is a metal hollow shaft structure 22, that is, the flexible base material layer 21 covers the entire The metal hollow shaft structure 22 and the flexible base material layer 21 are made of profiled rubber or sponge material. The metal hollow shaft structure 22 provides a mounting shaft hole 23 for the entire grinding wheel component, so that the grinding wheel component can be easily installed and fixed on the corresponding grinding device.

[0028] The outer surface of the flexible base material layer 21 is provided with a plurality of arc-shaped grooves, the arc-shaped grooves are arranged in parallel and at equal intervals, and the ar...

Embodiment 2

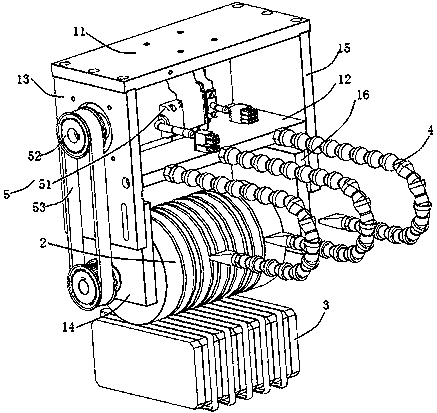

[0031] This embodiment discloses an automatic grinding device for a mobile phone case, which has the advantages of being able to realize automatic management, high grinding efficiency, ideal grinding effect, and being able to reduce the temperature of the grinding surface and remove slag in time, such as figure 2 As shown, the device includes a frame, a grinding wheel part 2 described in the first implementation, a mobile phone case clamp 3 , a universally adjusted cooling water pipe 4 and a motor drive assembly 5 .

[0032] continue figure 2 , the frame includes a connected upper support frame 11, a left support frame, a right support frame and a lower connecting plate 12. The upper support frame 11 may be provided with threaded holes for connecting the ends of moving devices such as robots or manipulators. The left support frame includes a left side plate 13 and a first fixing plate 14 that is detachably and fixedly connected to the left side plate 13 , and correspondingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com