4D printing method of functional gradient copper-based shape memory alloy intelligent component, and product

A technology of memory alloy and functional gradient, which is applied in the direction of improving energy efficiency, additive manufacturing, and process efficiency. It can solve the problems of limited complexity of parts, difficulty in achieving precise control of local positions, and cumbersome operation steps, and achieve strong adaptability. , smooth surface and convenient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

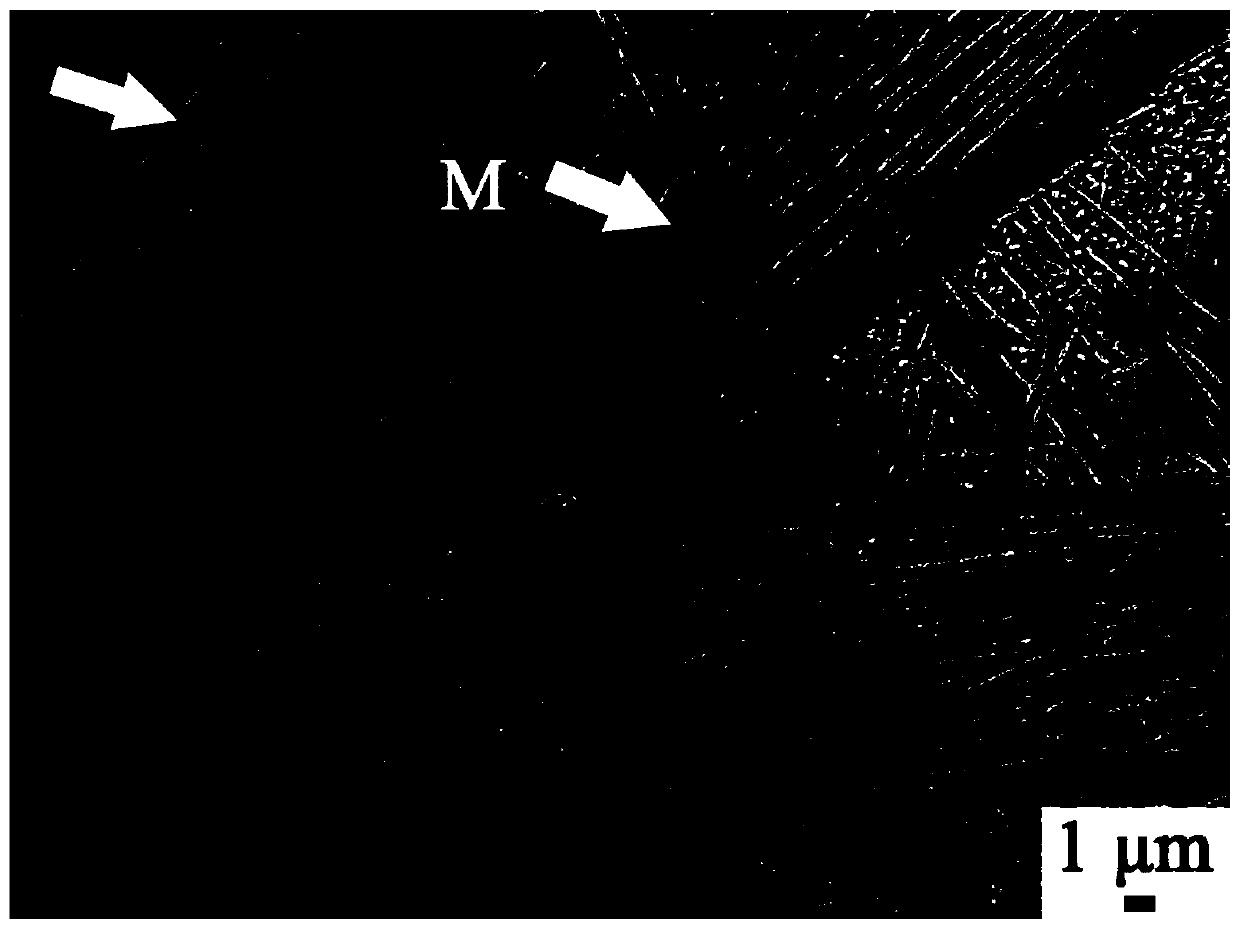

Image

Examples

Embodiment 1

[0044] 1) Use 3D modeling software to design such as figure 2 The three-dimensional model of the copper-based shape memory alloy smart component with functional gradient shown in the figure is divided into regions according to the application requirements of each part of the component. figure 2 Among them, 1 is the large deformation recovery area, 2 is the small deformation recovery area, and 3 is the bearing area. The length of the large deformation recovery area 1 is 40% of the overall length of the intelligent component, the length of the small deformation recovery area 2 is 30% of the overall length of the intelligent component, and the length of the bearing area 3 is 30% of the entire length of the intelligent component.

[0045] 2) Convert the 3D model into STL file format, use computer to identify different areas, use slicing software to slice each area in the computer, and input different forming process parameters in the SLM forming equipment according to the requir...

Embodiment 2

[0051] 1) Use 3D modeling software to design such as figure 2 The three-dimensional model of copper-based shape memory alloy intelligent component with functional gradient shown in the figure is divided into regions according to the required deformation and function of each part of the intelligent component. The length of the large deformation recovery area 1 is 30% of the overall length of the intelligent component, the length of the small deformation recovery area 2 is 50% of the overall length of the intelligent component, and the length of the bearing area 3 is 20% of the entire length of the intelligent component.

[0052] 2) Convert the 3D model into STL file format, use computer to identify different areas, use slicing software to slice each area in the computer, and input different forming process parameters in the SLM forming equipment according to the requirements of different areas .

[0053] 3) Send the dried Cu-32Zn-6Al powder into the powder feeding device of t...

Embodiment 3

[0058] 1) Use 3D modeling software to design such as figure 2 The three-dimensional model of the copper-based shape memory alloy intelligent component with functional gradient is shown, and the component is divided into regions according to the application requirements of each part of the component. Wherein the length of the large deformation recovery area 1 is 50% of the overall length of the intelligent component, the length of the small deformation recovery area 2 is 20% of the overall length of the intelligent component, and the length of the bearing area 3 is 30% of the entire length of the intelligent component.

[0059]2) Convert the 3D model into STL file format, use computer to identify different areas, use slicing software to slice each area in the computer, and input different forming process parameters in the SLM forming equipment according to the requirements of different areas .

[0060] 3) Send the dried Cu-34Zn-5Al powder into the powder feeding device of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com