Method for preparing functional gradient material using metal organic chemical vapor-phase deposition method

A functionally graded material and metal-organic chemistry technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of large material porosity, low interlayer bonding force, low mechanical strength, etc., to achieve High deposition rate, excellent performance, and good step coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: Preparation of Mo / Fe series functionally graded material by MOCVD method

[0052] 1. Design of Mo / Fe functionally graded materials

[0053] 1) Thermal and physical properties of Fe and Mo: The Mo / Fe system graded functional material has molybdenum on one side, iron on the other side, and a molybdenum-iron composite layer with a gradual transition in composition in the middle. Its advantage is that it can well alleviate the huge thermal stress caused by the difference in physical properties between molybdenum and iron, and has good mechanical properties, electrical and thermal conductivity, ablation resistance, and thermal fatigue resistance on the whole, making it able to Withstand large thermal fluctuations and mechanical stress, and can give full play to the respective characteristics of molybdenum and iron components. In addition, the composition distribution and organizational structure of this FGM material tend to be rationalized, which greatly reduc...

Embodiment 2

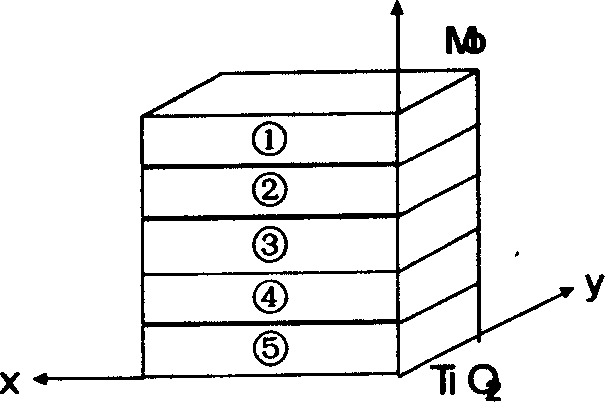

[0089] Embodiment 2: MOCVD method prepares metal-ceramic (Mo / SiO 2 ) functionally graded material

[0090] 1. Analysis model and composition design

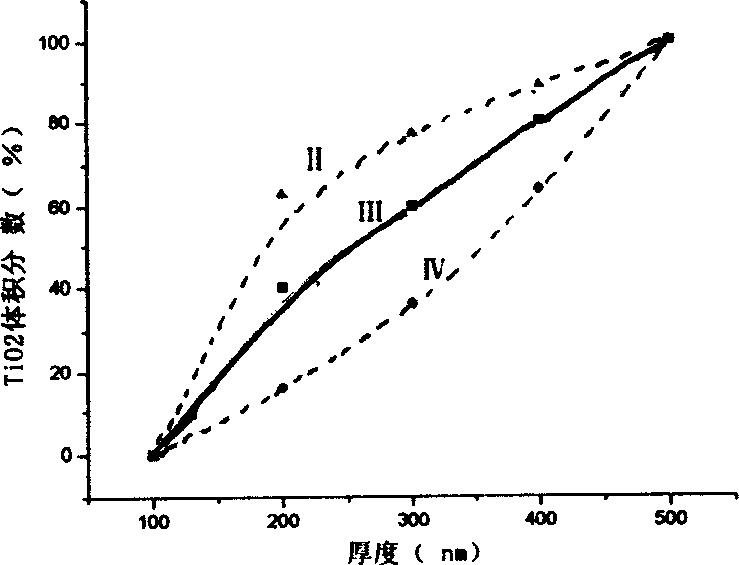

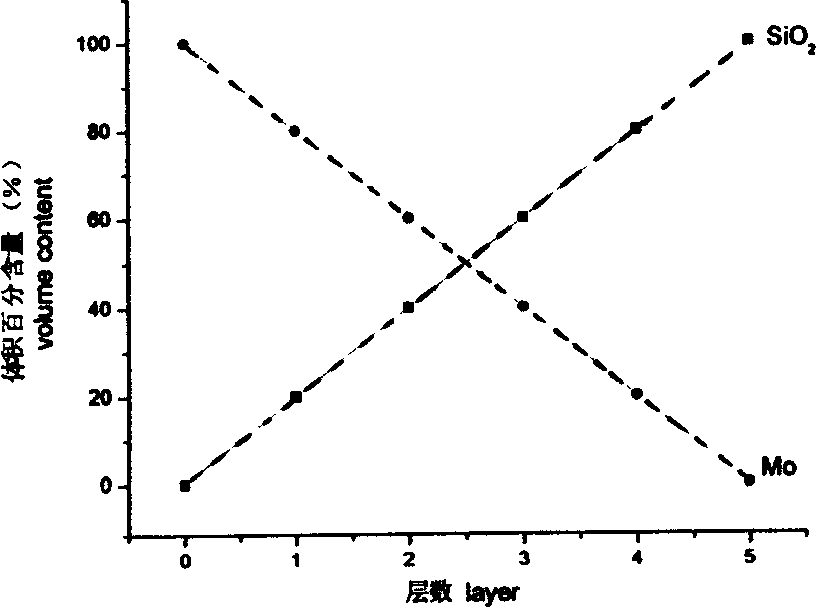

[0091] SiO 2 The thermal and physical properties of Mo and Mo are shown in Table 6. It can be seen from Table 6 that SiO 2The physical properties are very different from those of Mo, especially the mismatch of thermal properties, which will cause great thermal stress between discontinuous gradient layers. The inverse design idea of functionally graded materials (FGM) can solve this problem, because the design of reasonable gradient layer and composition is conducive to the smooth transition of material structure and performance. In the design, we assume that Mo / SiO 2 The functionally graded material consists of five layers, and each layer is made of uniform SiO 2 and Mo, the surface layer is pure metal Mo, and the bottom layer is pure ceramic Sio 2 , with a transition layer in the middle. According to the design idea an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com