An electrical fire intelligent protection device

A technology of intelligent protection and electrical fire protection, which is applied in the direction of protection against overcurrent, can solve problems such as thermal stress damage to bimetal sheets, slow response speed, and spark failure, and achieve fast circuit cut-off speed, rapid detection response, The effect of quick action response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

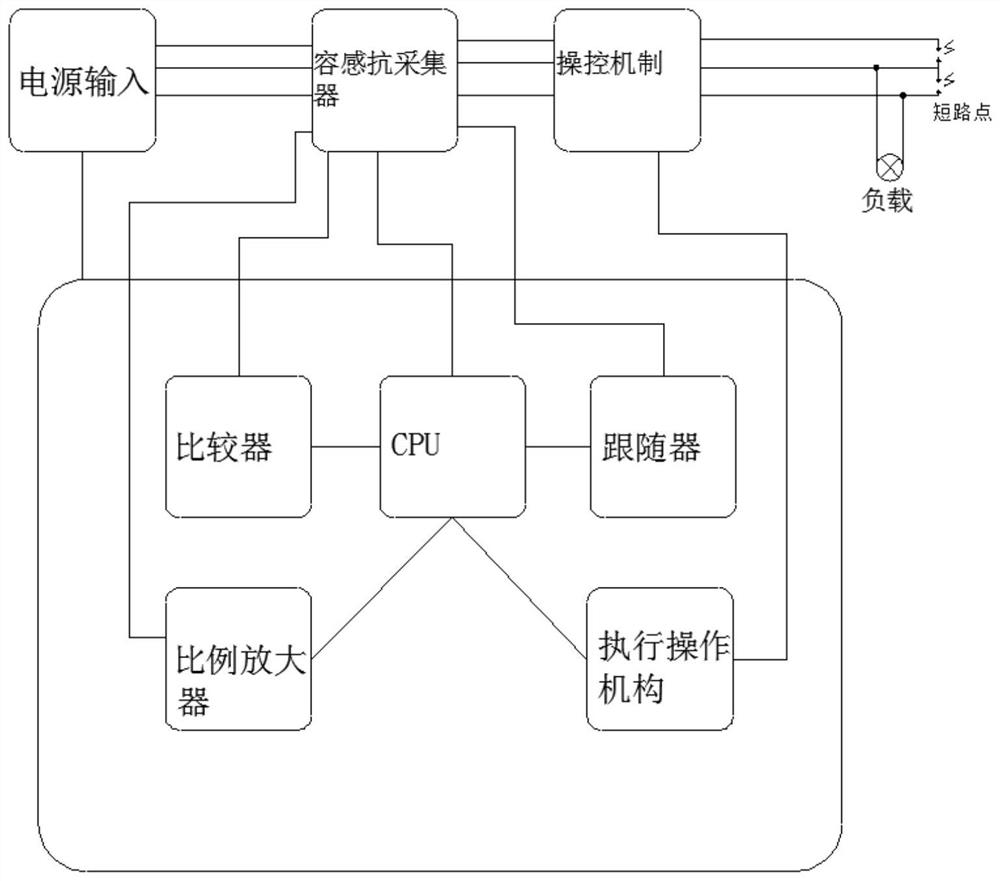

[0032] Refer Figure 1-4 , An electrical fire intelligent protection device, including:

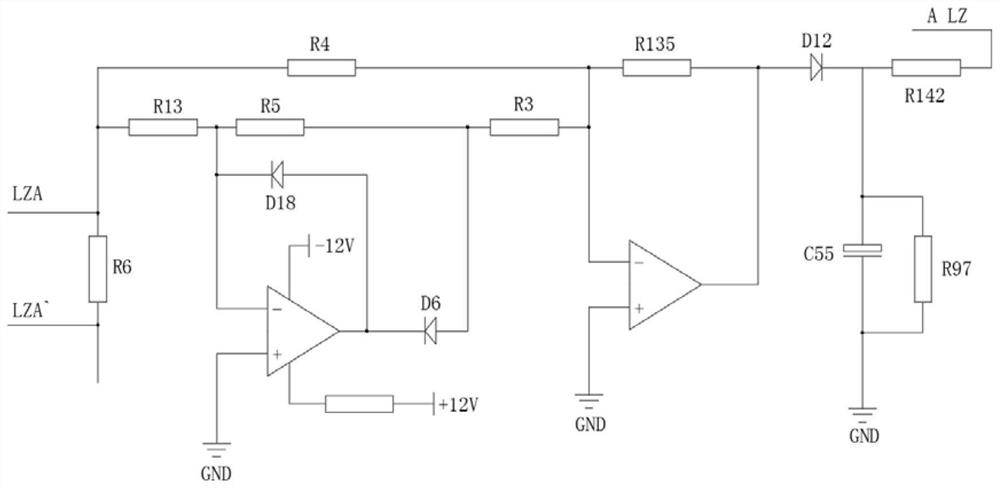

[0033] The processor is used to handle data logic comparisons returned by each part, and manipulate all central control systems.

[0034] Confelus-sensing anti-collector for acquiring current signal data delivery processor;

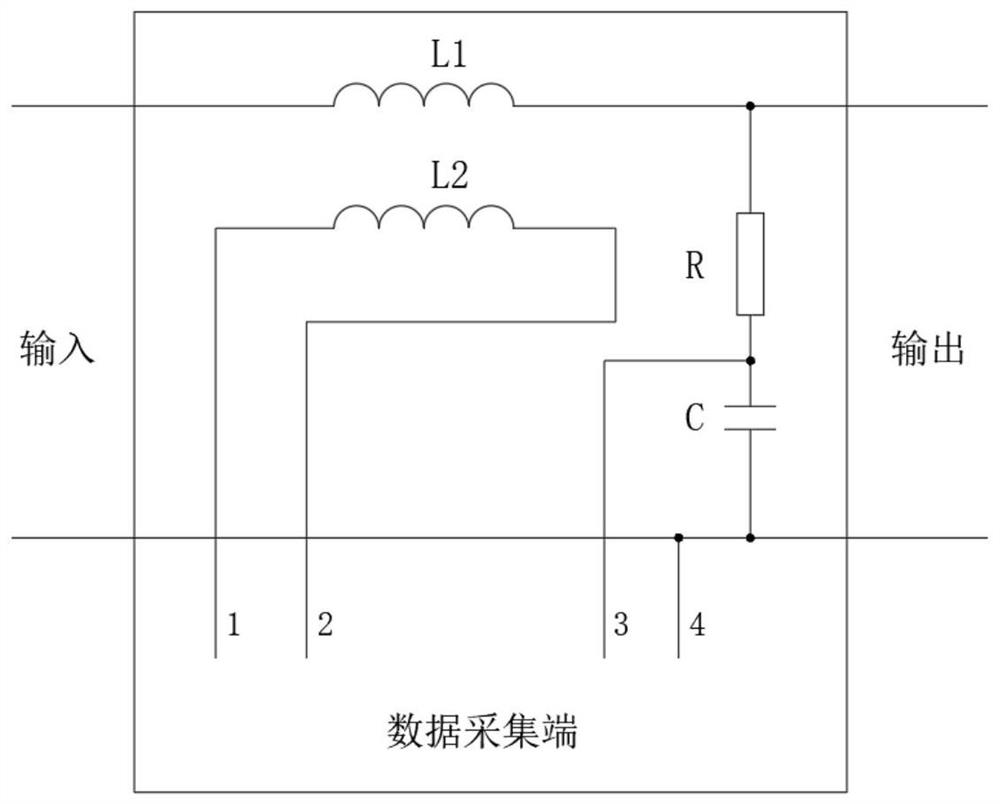

[0035] Processors, including pin 1, pin 2, pin 3, pin 4, pin 1, and pin 2 for inductive data acquisition, pin 3, for capacitive data acquisition, inductance Magnetic unsaturated inductance is two winding structures, collecting transient values of voltage current in real time;

[0036] Confelus-sensing anti-collector for acquiring current signal data delivery proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com