Lanthanum-modified manganese oxide catalyst, and preparation method and application thereof

A technology of manganese oxide and catalyst, which is applied in the field of catalyst to achieve the effect of high specific surface area and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

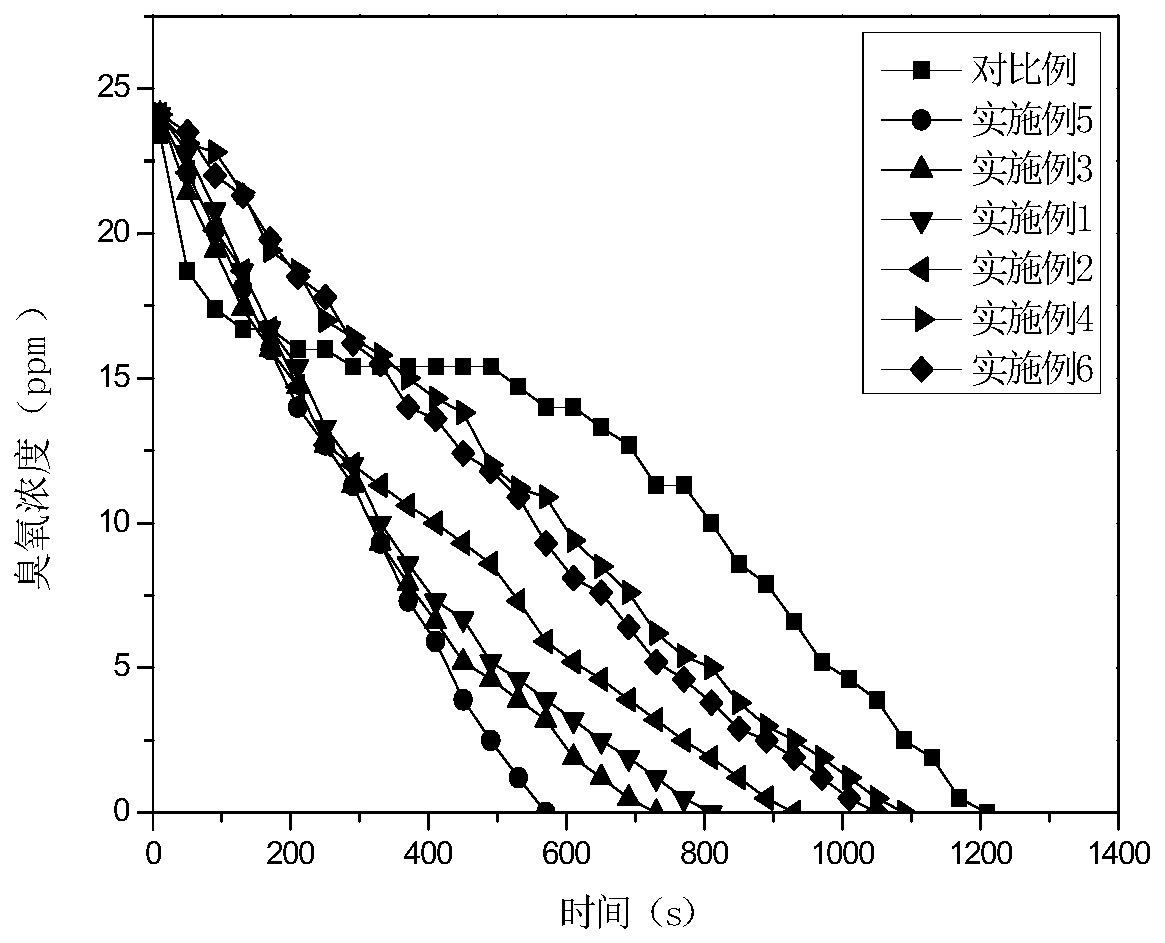

Examples

Embodiment 1

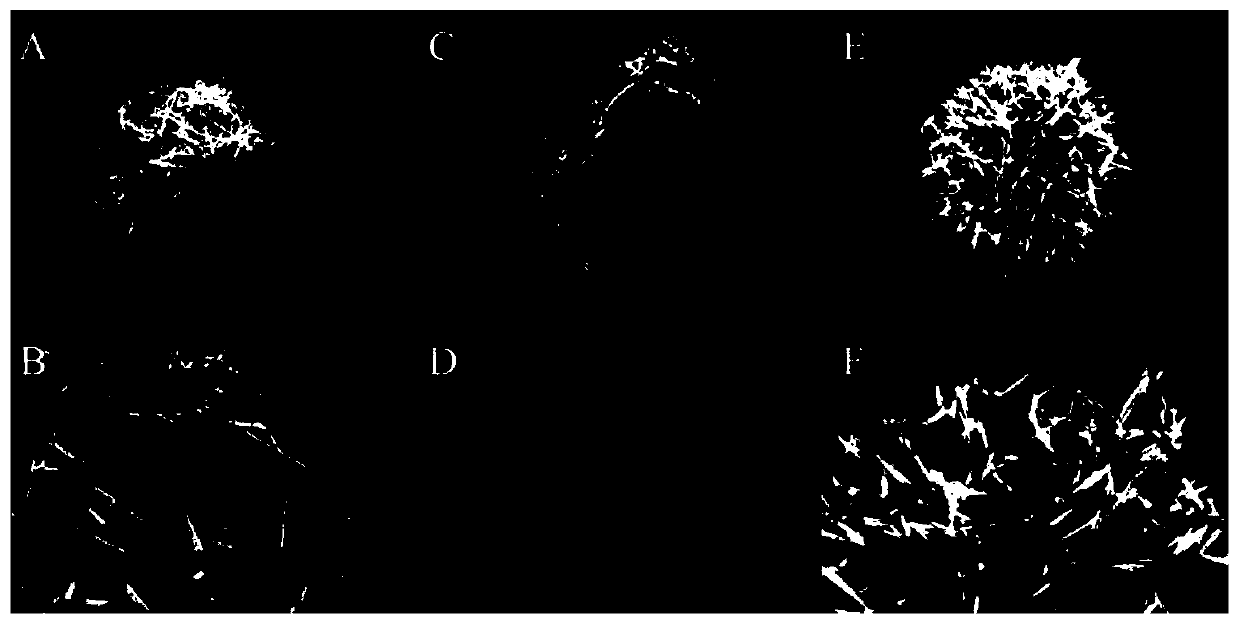

[0032] A kind of embodiment of the preparation method of the lanthanum-modified manganese oxide catalyst of the present invention, this preparation method comprises the following steps:

[0033] (1) At room temperature, manganese sulfate monohydrate and potassium permanganate are dissolved in deionized water in a mol ratio of 3:8, and stirred evenly to obtain a mixed solution;

[0034] (2) subjecting the mixed solution obtained in step (1) to hydrothermal treatment, the conditions of hydrothermal treatment are temperature 90°C, time 24h, and after the end, the obtained solid product is washed with deionized water, filtered, and dried to obtain a black solid;

[0035] (3) Add lanthanum nitrate hydrate to a solution of a certain concentration and add it to the black solid obtained in step (2), stir evenly and let it stand for a while to obtain a mixture A, wherein the La atom in the lanthanum salt and the La atom in the black solid The mass ratio of Mn atoms is m La :m Mn =0.0...

Embodiment 2

[0039] A kind of embodiment of the preparation method of the lanthanum-modified manganese oxide catalyst of the present invention, this preparation method comprises the following steps:

[0040] (1) At room temperature, manganese sulfate monohydrate and ammonium persulfate are dissolved in deionized water at a molar ratio of 1:1, and stirred evenly to obtain a mixed solution;

[0041] (2) The mixed solution obtained in step (1) is subjected to hydrothermal treatment, the conditions of hydrothermal treatment are temperature 160°C, time 12h, and after the end, the obtained solid product is sequentially washed with deionized water, filtered, and dried to obtain a black solid;

[0042] (3) Add lanthanum nitrate hydrate to a solution of a certain concentration and add it to the black solid obtained in step (2), stir evenly and let it stand for a while to obtain a mixture A, wherein the La atom in the lanthanum salt and the La atom in the black solid The mass ratio of Mn atoms is m ...

Embodiment 3

[0046] A kind of embodiment of the preparation method of the lanthanum-modified manganese oxide catalyst of the present invention, this preparation method comprises the following steps:

[0047](1) At room temperature, manganese sulfate monohydrate and potassium permanganate are dissolved in deionized water in a mol ratio of 3:8, and stirred evenly to obtain a mixed solution;

[0048] (2) The mixed solution obtained in step (1) is subjected to hydrothermal treatment, the conditions of hydrothermal treatment are temperature 160°C, time 12h, and after the end, the obtained solid product is sequentially washed with deionized water, filtered, and dried to obtain a black solid;

[0049] (3) Add lanthanum nitrate hydrate to a solution of a certain concentration and add it to the black solid obtained in step (2), stir evenly and let it stand for a while to obtain a mixture A, wherein the La atom in the lanthanum salt and the La atom in the black solid The mass ratio of Mn atoms is m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com