A kind of normal temperature high-strength adhesive wear-resistant material and its preparation method

A wear-resistant material and high-strength technology, used in the field of adhesive wear-resistant materials, can solve the problems of adhesive coating damage and peeling, not taking into account, and achieve the effect of reducing the area, avoiding difficult control, and good thermal expansion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

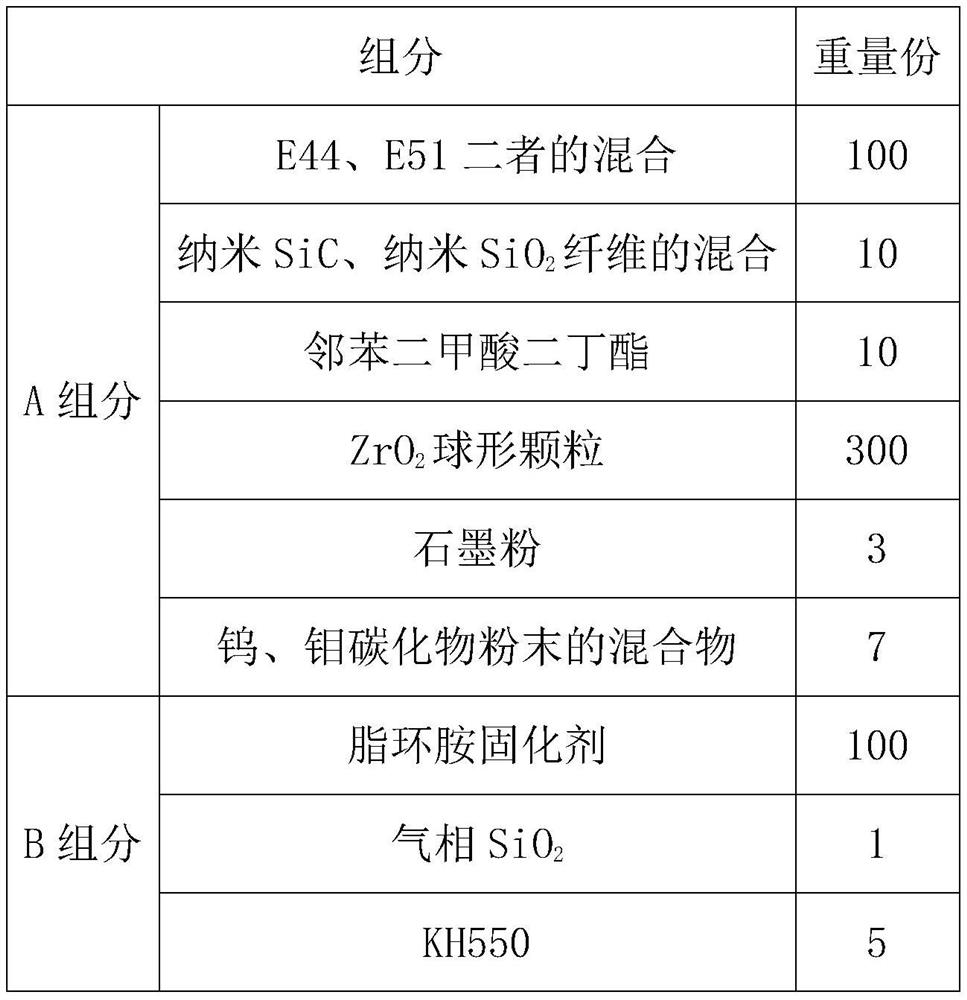

[0049] A high-strength adhesive wear-resistant material at room temperature, composed of A and B components.

[0050] The composition of A component and the parts by weight of each composition are as follows:

[0051] Mixture of E44 and E51 100 parts

[0052] Nano-SiC, Nano-SiO 2 fiber blend 10 parts

[0053] 10 parts of dibutyl phthalate

[0054] ZrO 2 300 parts of spherical particles

[0055] 3 parts graphite powder

[0056] 7 parts mixture of tungsten and molybdenum carbide powder

[0057] The composition of B component and the parts by weight of each composition are as follows:

[0058] Alicyclic amine curing agent 100 parts

[0059] Vapor SiO 2 1 copy

[0060] KH550 5 copies;

[0061] Among them, ZrO 2 The purity of spherical particles is above 95%, and its particle size specifications are composed of: 2.0mm 90 parts by weight, 1.0mm 120 parts by weight, 0.5mm 90 parts by weight; the particle size range of graphite powder is 200-400 mesh; nano-SiC, nano-SiO ...

Embodiment 2

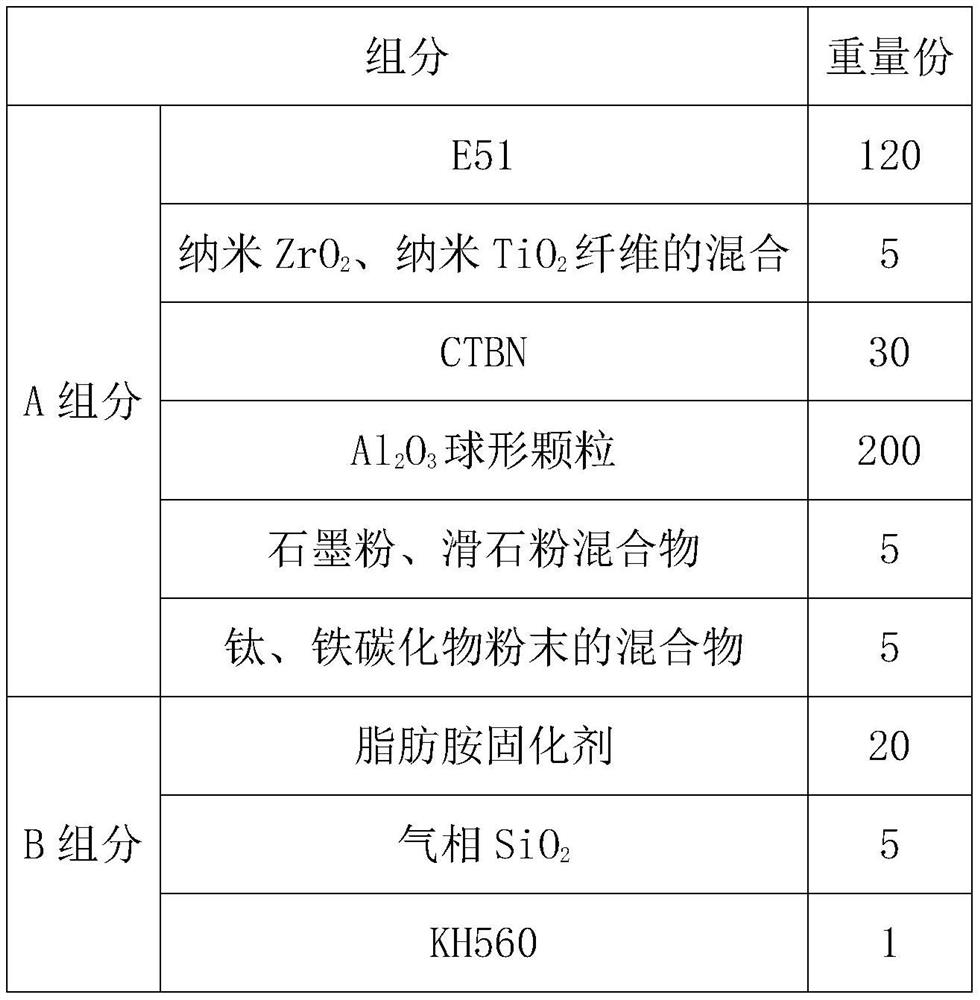

[0069] A high-strength adhesive wear-resistant material at room temperature, composed of A and B components.

[0070] The composition of A component and the parts by weight of each composition are as follows:

[0071] E51 120 copies

[0072] Nano-ZrO 2 , Nano TiO 2 fiber blend 5 parts

[0073] CTBN 30 copies

[0074] al 2 o 3 200 parts of spherical particles

[0075] 5 parts of graphite powder and talcum powder mixture

[0076] 5 parts of mixture of titanium and iron carbide powder

[0077] The composition of B component and the parts by weight of each composition are as follows:

[0078] Aliphatic amine curing agent 20 parts

[0079] Vapor SiO 2 5 copies

[0080] 1 copy of KH560;

[0081] Among them, Al 2 o 3 The purity of spherical particles is above 95%, and its particle size specifications are composed of: 3.5mm 60 parts by weight, 2.0mm 80 parts by weight, 1.0mm 60 parts by weight; the particle size range of graphite powder and talcum powder mixture is 200...

Embodiment 3

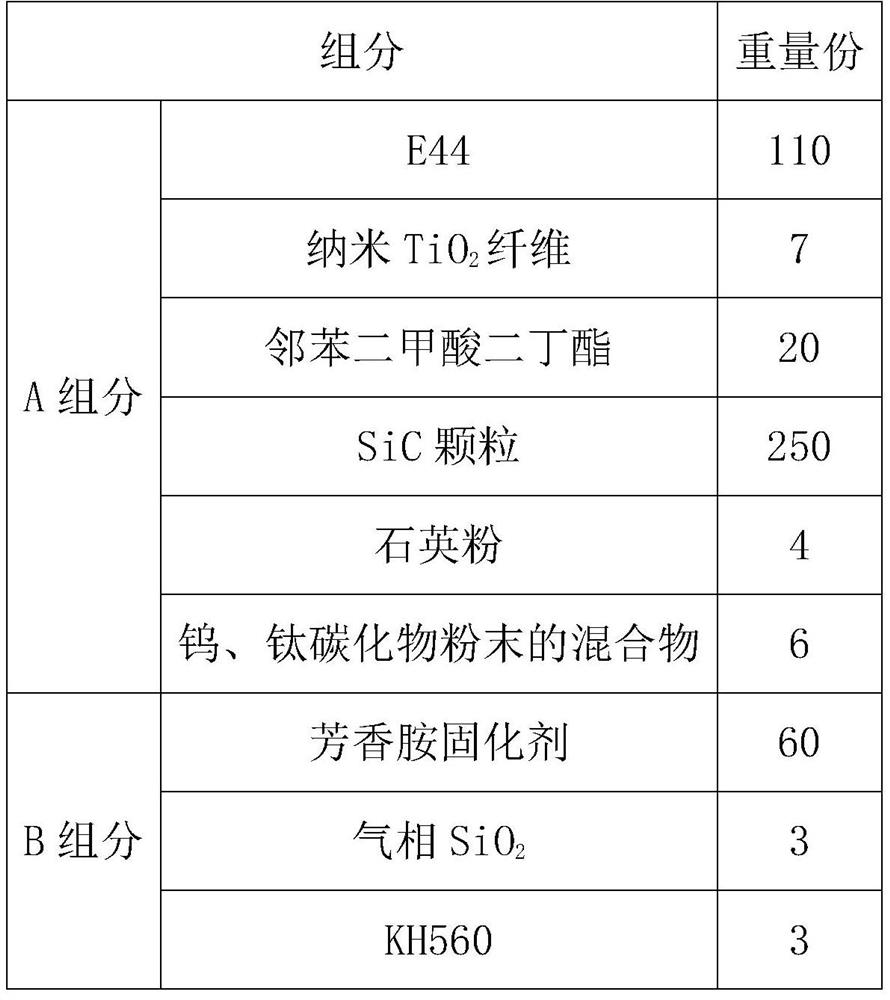

[0089] A high-strength adhesive wear-resistant material at room temperature, composed of A and B components.

[0090] The composition of A component and the parts by weight of each composition are as follows:

[0091] E44 110 copies

[0092] Nano-TiO 2 7 servings of fiber

[0093] 20 parts of dibutyl phthalate

[0094] SiC particles 250 parts

[0095] Quartz powder 4 parts

[0096] 6 parts mixture of tungsten and titanium carbide powder

[0097] The composition of B component and the parts by weight of each composition are as follows:

[0098] 60 parts of aromatic amine curing agent

[0099] Vapor SiO 2 3 copies

[0100] KH560 3 copies;

[0101] Among them, the particle size specifications of SiC particles are: 60 parts by weight of 5 mesh, 80 parts by weight of 6 mesh, 60 parts by weight of 8 mesh, 37.5 parts by weight of 30 mesh, 12.5 parts by weight of 100 mesh; the particle size range of quartz powder is 200-400 mesh ; Nano-TiO 2 The particle size range of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com