Nitrogen removal and phosphorus removal active biological carrier for sewage treatment, and preparation method thereof

A biological carrier, nitrogen and phosphorus removal technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, granular microbial carrier treatment, etc., can solve the problem of poor hydrophilicity and biological affinity, affecting biological carriers Use efficiency, low number of film-hanging microorganisms, etc., to achieve the effect of enhancing hydrophilic performance, facilitating rapid attachment, and good denitrification and denitrification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

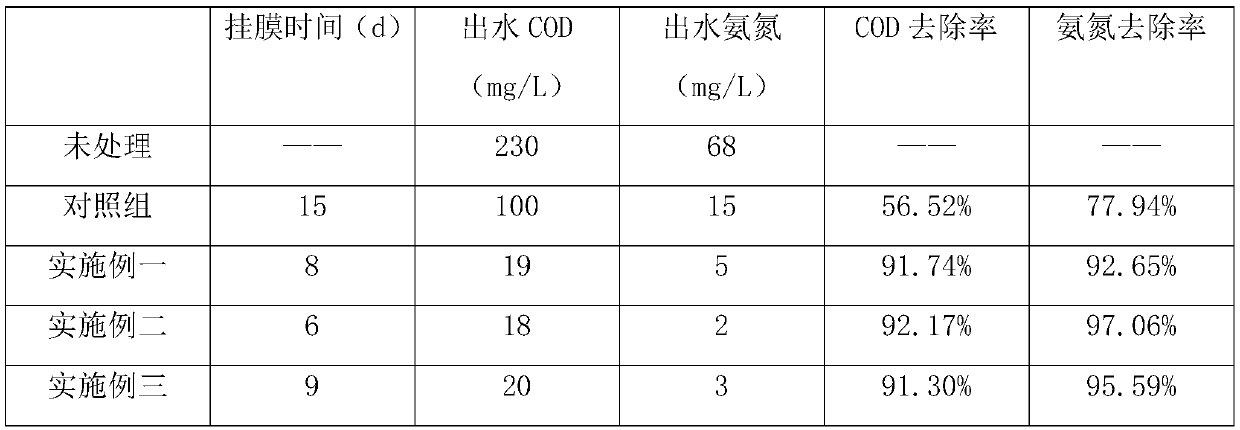

Examples

Embodiment 1

[0029] The parts by weight of each preparation raw material of the biological carrier of the present embodiment are as follows: 75 parts of high-density polyethylene, 0.08 part of polyhydroxy fatty acid amide, 0.9 part of compound enzyme, 15 parts of rust, 20 parts of modified loofah, shell powder / oxidized 8 parts of zinc hollow microspheres.

[0030] The preparation of shell powder / zinc oxide is as follows: take the shell powder at a heating rate of 10 °C / min to 650 °C, and calcinate it in an argon atmosphere at 650 °C for 3 h, take it out after cooling, and put it in a pulverizer to crush it until it exceeds 600 °C. Mesh sieve, then placed in an oxygen atmosphere at 1250 ° C for 1 hour, cooled, taken out, and placed in a pulverizer to pulverize until passing through a 1000 mesh sieve to obtain pretreated shell powder. Add zinc nitrate per liter of ethanol solution with a volume concentration of 65% to prepare a zinc salt solution with a concentration of 2mol / L, add 15g of pr...

Embodiment 2

[0036] The parts by weight of each preparation raw material of the biological carrier of the present embodiment are as follows: 65 parts of high-density polyethylene, 0.10 part of polyhydroxy fatty acid amide, 0.5 part of compound enzyme, 13 parts of rust, 25 parts of modified loofah, shell powder / oxidized 10 parts of zinc hollow microspheres.

[0037] The preparation of shell powder / zinc oxide is as follows: take the shell powder at a heating rate of 20 °C / min to 650 °C, and calcinate it in an argon atmosphere at 650 °C for 4 hours, take it out after cooling, and put it in a pulverizer to pulverize it until it exceeds 600 °C. Mesh sieve, then placed in an oxygen atmosphere at 1250 ° C for 1 hour, cooled, taken out, and placed in a pulverizer to pulverize until passing through a 1000 mesh sieve to obtain pretreated shell powder. Add zinc sulfate to each liter of ethanol solution with a volume concentration of 65% to prepare a zinc salt solution with a concentration of 2mol / L, ...

Embodiment 3

[0043] The parts by weight of each preparation raw material of the biological carrier of the present embodiment are as follows: 70 parts of high-density polyethylene, 0.12 part of polyhydroxy fatty acid amide, 0.8 part of compound enzyme, 5 parts of rust, 30 parts of modified loofah, shell powder / oxidized 12 parts of zinc hollow microspheres.

[0044] The preparation of shell powder / zinc oxide is as follows: Take the shell powder to 650°C at a heating rate of 15°C / min, and calcinate it in an argon atmosphere at 650°C for 3.5h, take it out after cooling, and put it in a pulverizer to pulverize it until 600-mesh sieve, and then placed in an oxygen atmosphere at 1250°C for 1 hour, cooled, taken out, and pulverized in a pulverizer until it passed a 1,000-mesh sieve to obtain pretreated shell powder. Add zinc sulfate to each liter of ethanol solution with a volume concentration of 65% to prepare a zinc salt solution with a concentration of 2mol / L, add 14g of pretreated shell powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com