Rapid preparing method of large-specific-surface-area SAPO-34 molecular sieve

A SAPO-34 technology with large specific surface area, applied in the direction of molecular sieve catalyst, molecular sieve characteristic silicoaluminophosphate, molecular sieve and alkali-exchanged phosphate, etc. Small particle thickness, reducing the effect of carbon deposition reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

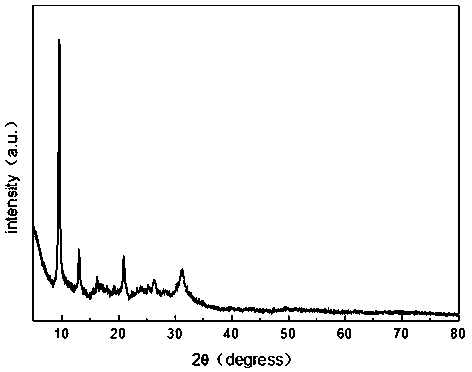

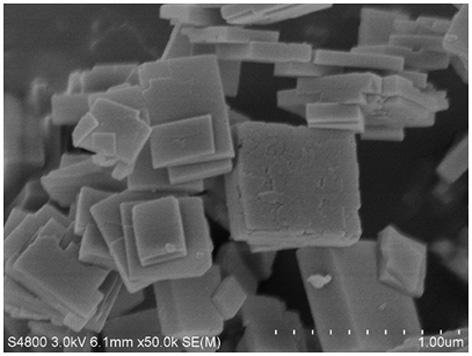

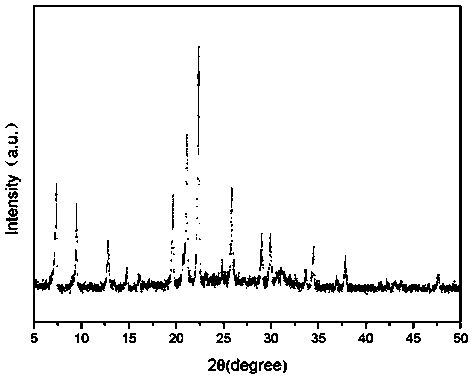

Embodiment 1

[0026] Al in product 2 O 3 , P 2 O 5 , SiO 2 , TEAOH, H 2 The molar ratio of O and glycerol is 1:2:0.6:4:140:15. Weigh 4.085g aluminum isopropoxide, 4.6118g phosphoric acid, 1.2000g silica sol, 16.8297g TEAOH, 12.0494g deionized water, 13.9530g glycerol. Dissolve TEAOH in deionized water, slowly add aluminum isopropoxide, stir at room temperature for 1-5 h until the solution is clear; then add silica sol and phosphoric acid under stirring conditions, and react for 2 hours respectively, and finally add glycerol and stir for aging 3d; Then transfer the mixture to a stainless steel kettle with a PTFE liner, and place it in an oven at 180 ℃ to crystallize for 4 hours. Take out centrifugation (8000r / min) and separate for 30min, then wash with water until the pH is lower than 9, and then dry at 110 ℃, and finally put it in a muffle furnace, roast at 550 ℃ for 5 h, remove the organic template, and get the target product (S1).

Embodiment 2

[0028] Al in product 2 O 3 , P 2 O 5 , SiO 2 , TEAOH, H 2 The molar ratio of O to ethylene glycol is 1:2:0.6:4:140:15. Weigh 4.085g aluminum isopropoxide, 4.6118g phosphoric acid, 1.2000g silica sol, 16.8297g TEAOH, 12.1262g deionized water, 9.4042g ethylene glycol. Dissolve TEAOH in deionized water, slowly add aluminum isopropoxide, stir at room temperature for 1-5 h until the solution is clear; then add silica sol and phosphoric acid under stirring conditions, and react for 2 hours respectively, and finally add ethylene glycol and stir for aging 3d; Then transfer the mixture to a stainless steel kettle with a PTFE lining, and place it in an oven at 200 ℃ to crystallize for 4 h. Take out centrifugation (8000r / min) and separate for 30min, then wash with water until the pH is lower than 9, and then dry at 110 ℃, and finally put it in a muffle furnace, roast at 500 ℃ for 6 h, remove the organic template, and get the target product (S2).

Embodiment 3

[0030] Al in product 2 O 3 , P 2 O 5 , SiO 2 , TEAOH, H 2 The molar ratio of O and isopropanol is 1:2:0.6:4:140:15. Weigh 4.085g aluminum isopropoxide, 4.6118gg phosphoric acid, 1.2000g silica sol, 16.8297g TEAOH, 12.0979g deionized water, 9.1015g isopropanol. Dissolve TEAOH in deionized water, slowly add aluminum isopropoxide, stir at room temperature for 1-5 h until the solution is clear; then add silica sol and phosphoric acid under stirring conditions, and react for 2 hours respectively, and finally add isopropanol and stir for aging 3d; Then transfer the mixture to a stainless steel kettle with a PTFE lining, and place it in an oven at 180 ℃ to crystallize for 4 hours. Take out centrifugation (8000r / min) and separate for 30min, then wash with water until the pH is lower than 9, and then dry at 110 ℃, and finally put it in a muffle furnace, roast at 550 ℃ for 5 h, remove the organic template, and get the target product (S3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com