Cutter pose optimization method

An optimization method, tool technology, applied in the field of machinery to improve surface properties, avoid interference and chatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

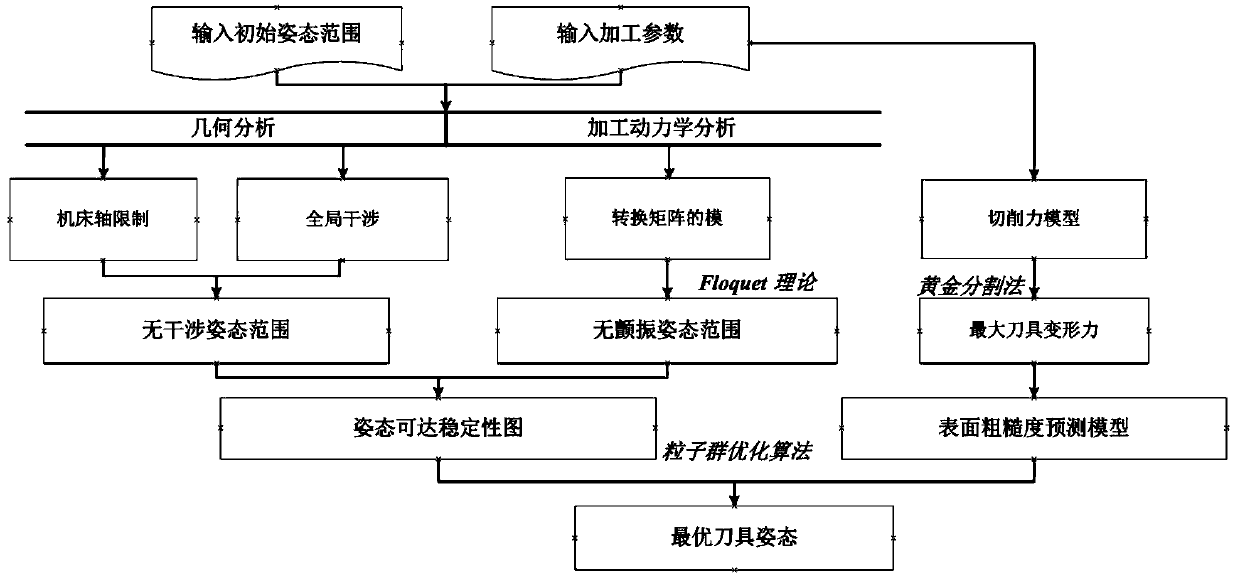

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

[0061] Glossary:

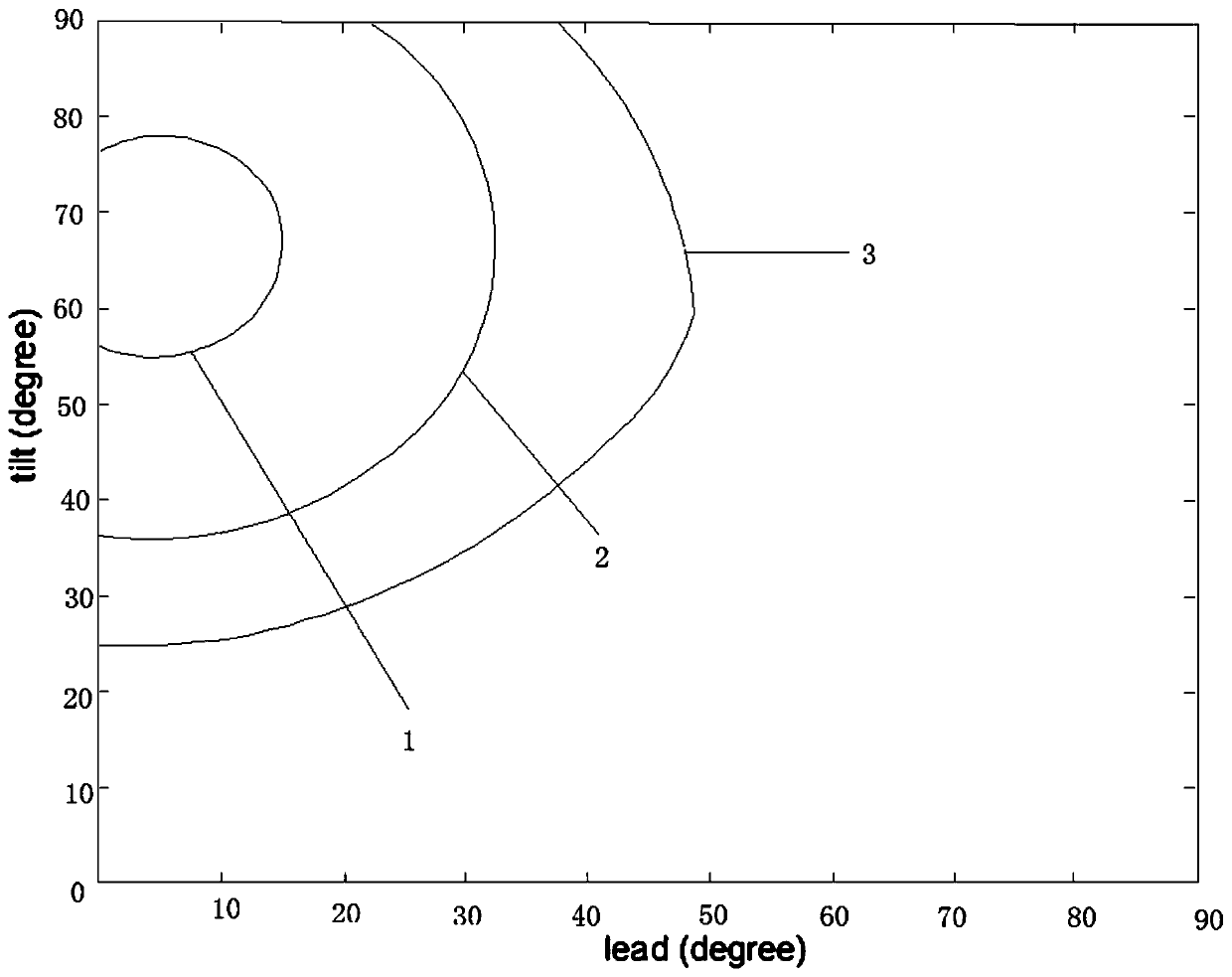

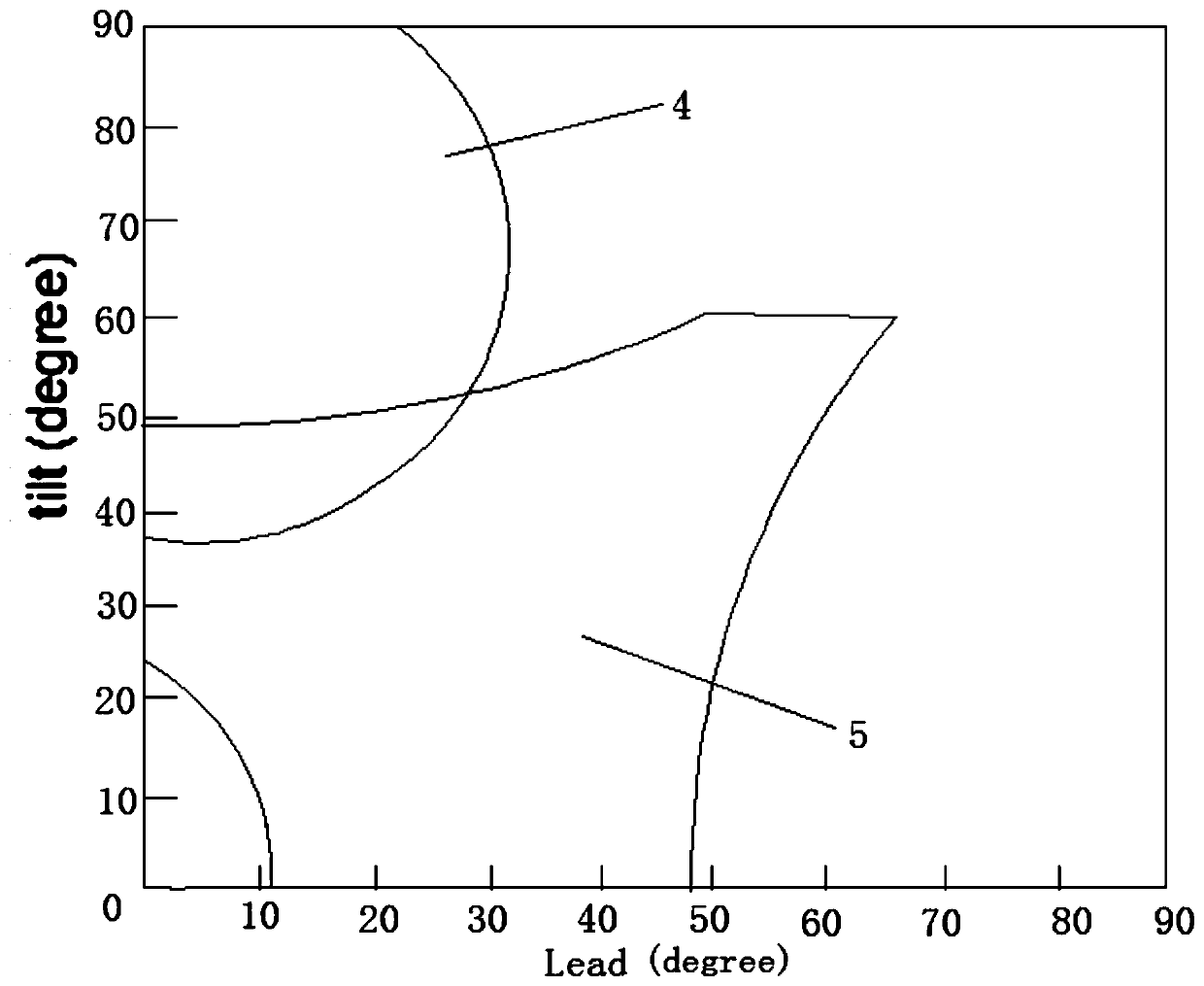

[0062] Tool attitude: Given a tool contact point, expressed by the tool’s lead angle α and inclination β, that is, (α i , β i ) indicates that the lead angle is: the angle between the tool axis projected onto the XOZ plane of the feed coordinate system and the Z axis of the feed coordinate system. The inclination angle is: the angle between the tool axis projected onto the YOZ plane of the feed coordinate system and the Z axis of the feed coordinate system. Since the tool attitude with a negative angle is usually not used in actual machining, the ranges of lead angle α and inclination β in this method are both (0°, 90°).

[0063] Feed coordinate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com