Flexible printed circuit board and manufacturing method thereof

A flexible printing and circuit board technology, applied in printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of tin-copper alloy layer disconnection, increase manufacturing cost, disconnection reliability, etc., and achieve enhanced bending performance. , The effect of preventing the generation of voids and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

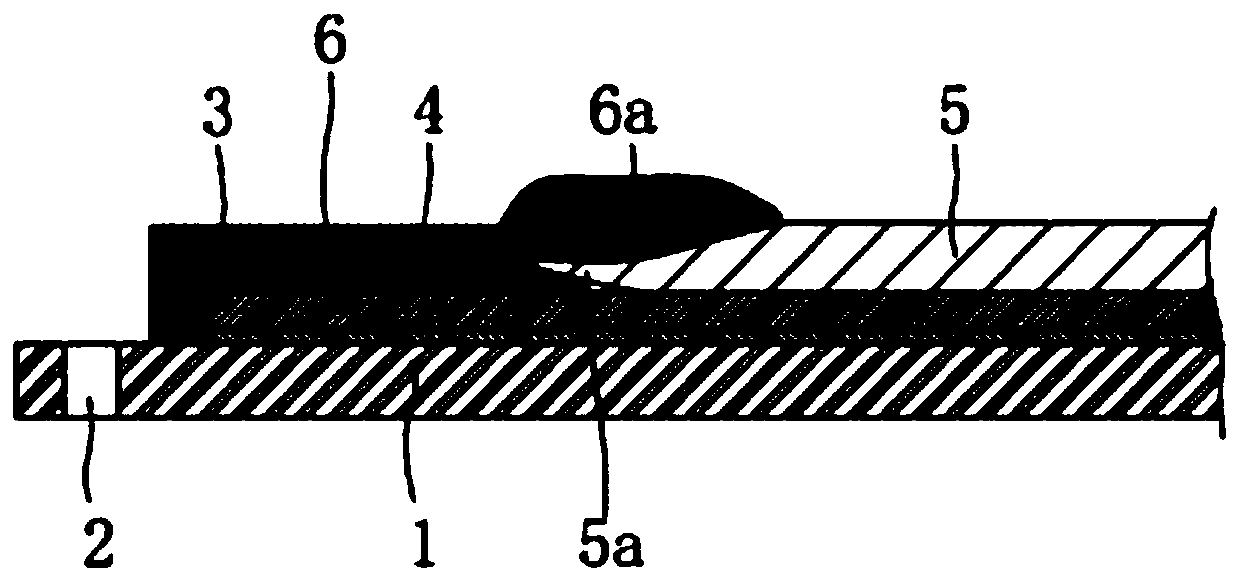

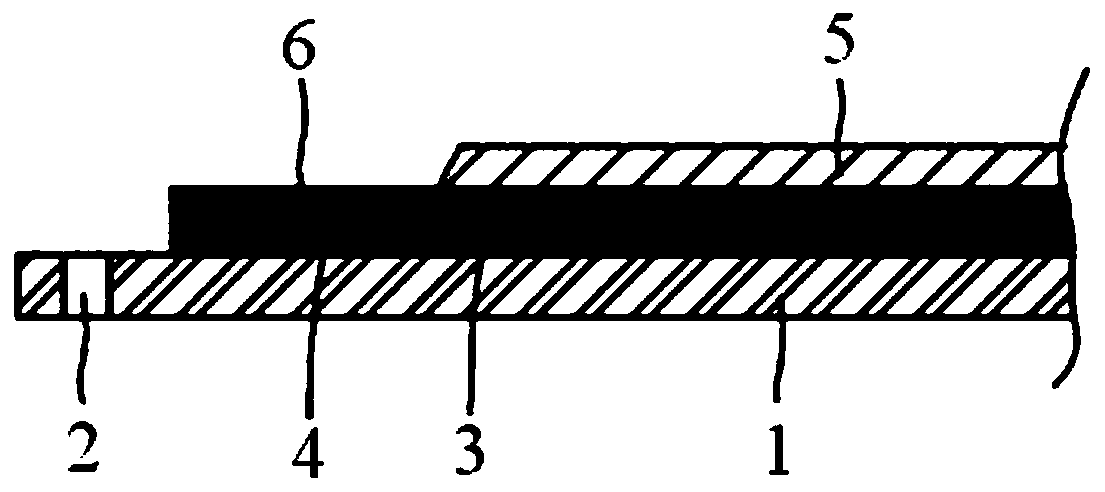

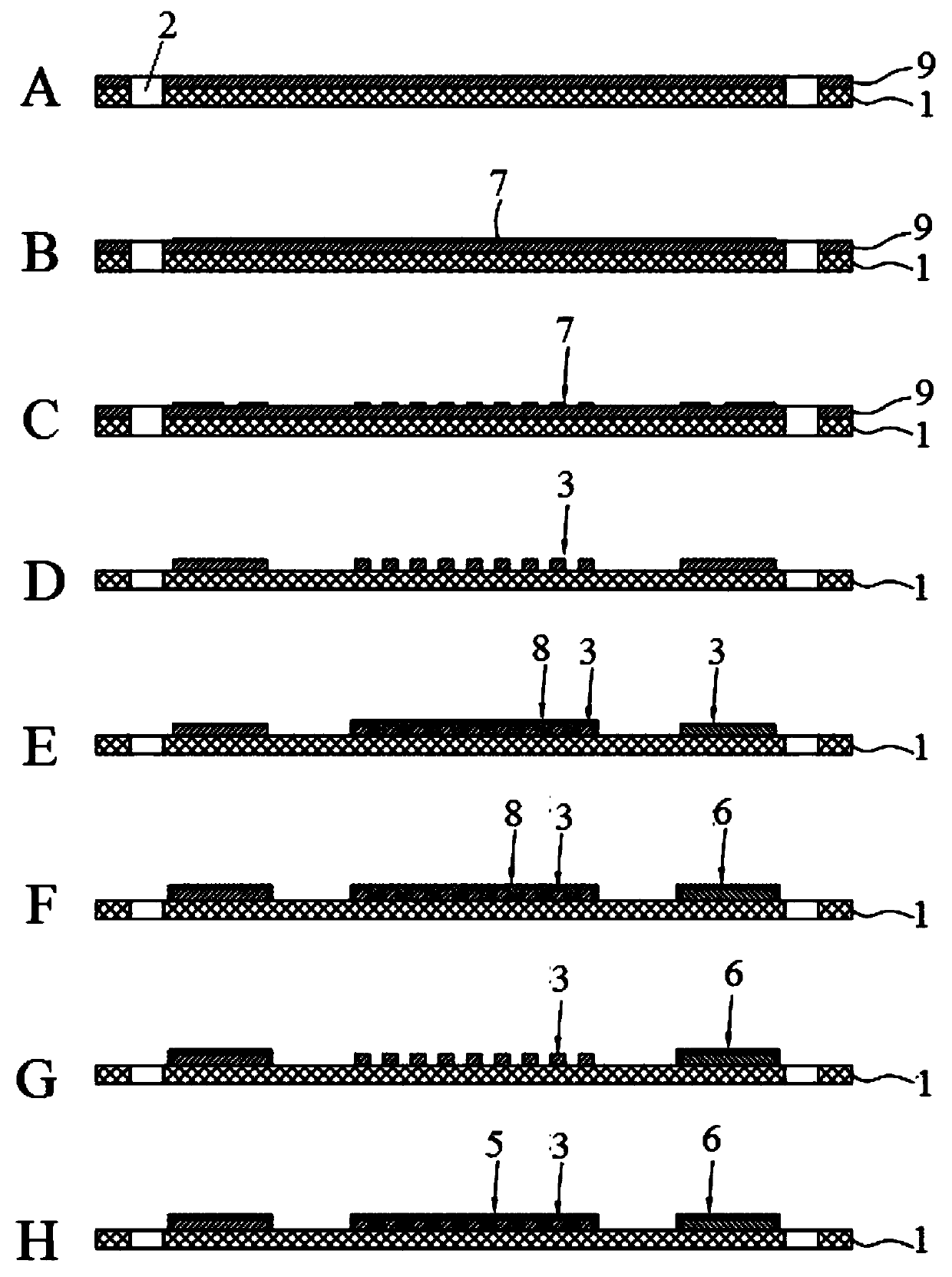

[0034] A method for manufacturing a flexible printed circuit board, the steps comprising:

[0035] First, apply an adhesive 4 on one side of the flexible and insulating plastic film-like insulating substrate 1, and use the adhesive 4 to press the conductor layer 9 on the insulating substrate 1. The conductor used here is preferably copper foil, and the insulation The general thickness of the substrate 1 is 12.5-50 μm, and then the sprocket holes 2 are punched continuously at certain intervals using a mold;

[0036] Then, as the traditional processing method, after the photoresist 7 is coated on the surface of the conductor, the conductor pattern 3 is formed by exposure and etching, and the unnecessary photoresist is removed with an alkaline liquid. Inner pins 3a of semiconductors, outer pins 3b for connection to other printed circuit boards or electronic components, etc., and plating leads used in electrolytic plating, etc.;

[0037] Next, in order to protect the conductor pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com