Set of cutting inserts and methods of making a set of cutting inserts

A technology of cutting inserts and cutting edges, applied in the manufacture of tools, additive manufacturing, accessories of tool holders, etc., can solve the problems of difficult handling and fixing, difficulty in pressing thin inserts, difficulty in grooving or cutting inserts, etc., to reduce losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

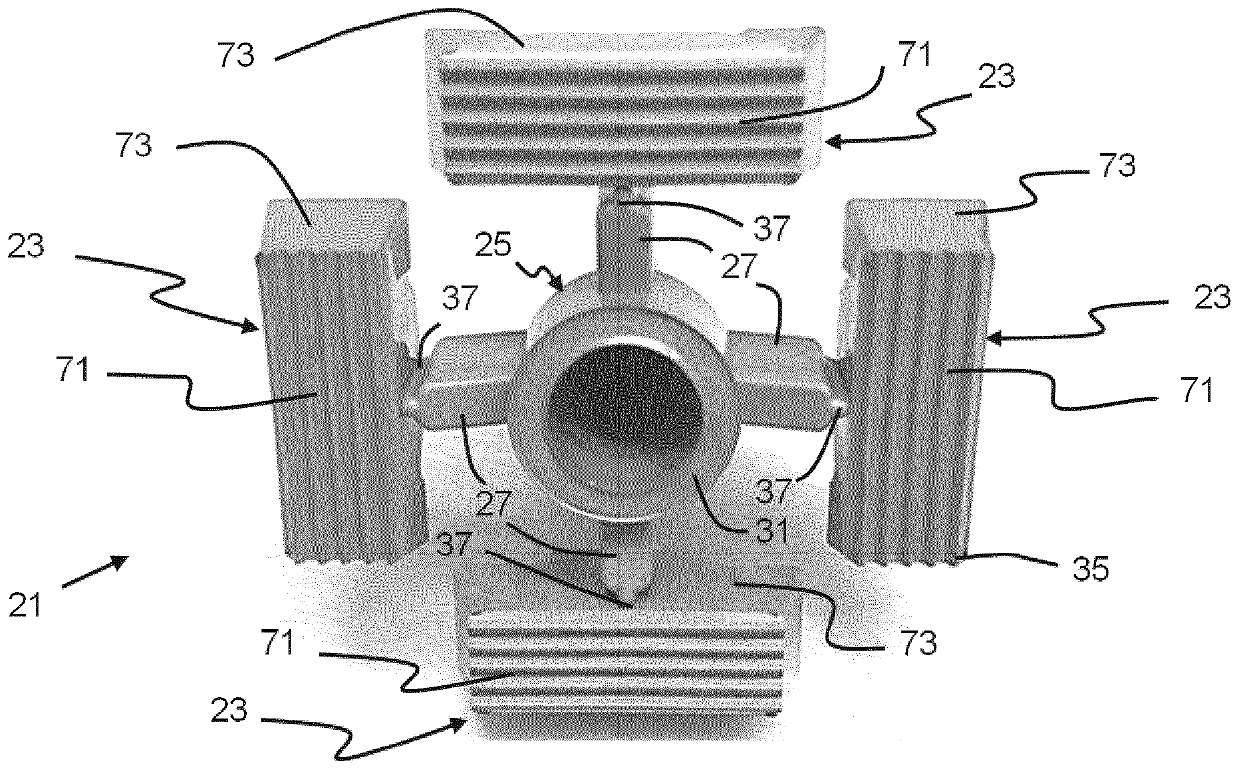

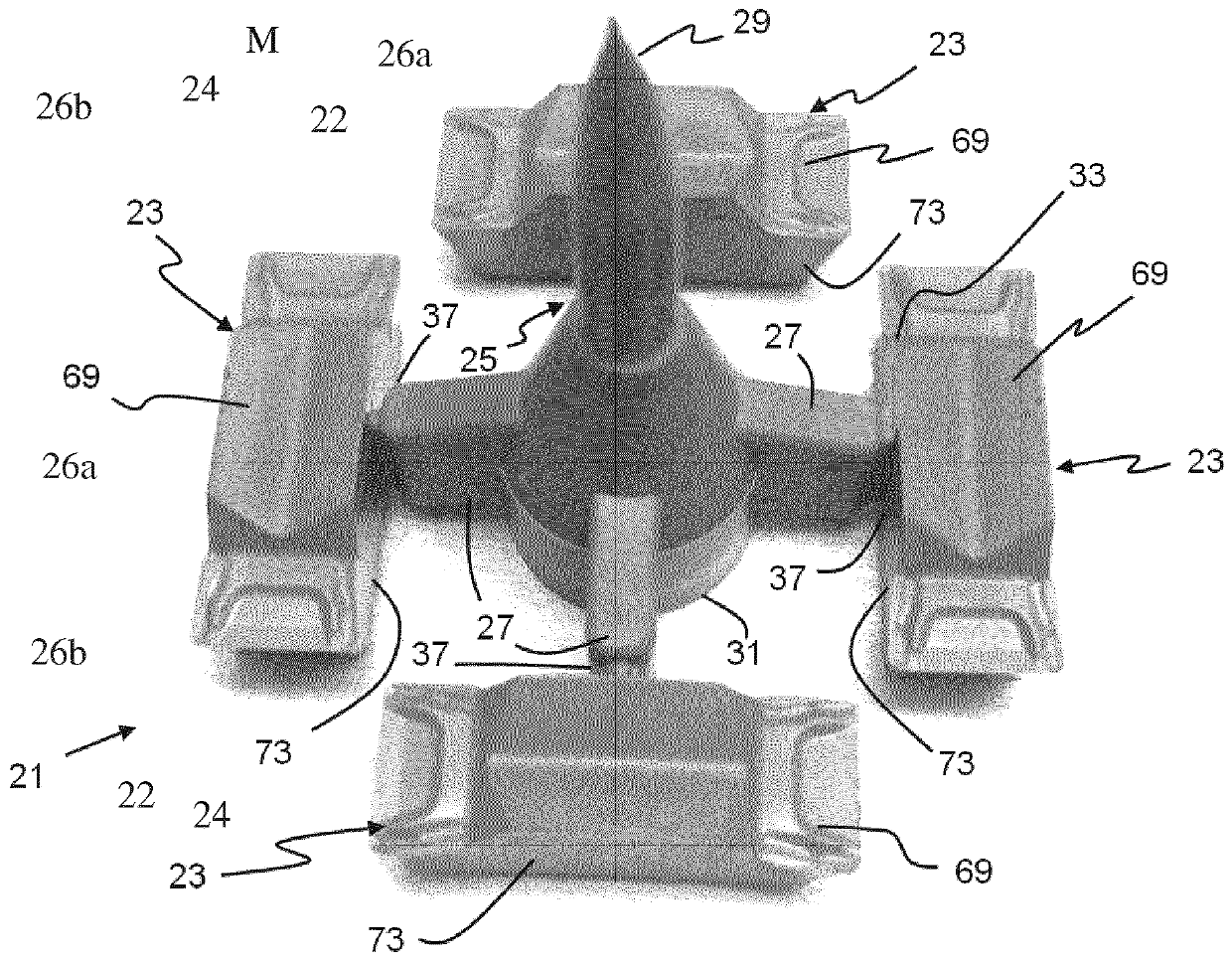

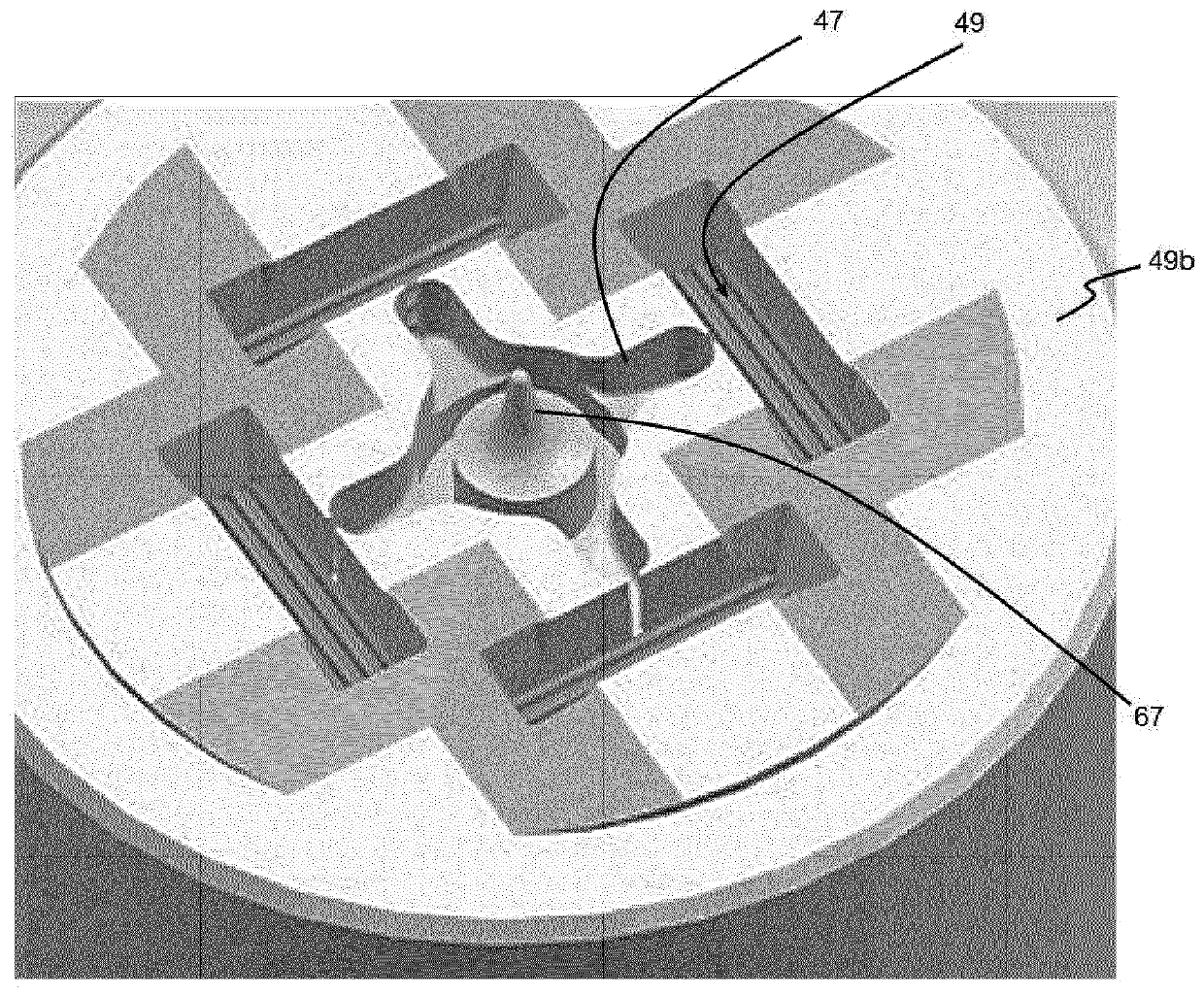

[0034] According to one aspect of the invention a set 21 of cutting inserts 23 in Figure 1A and 1B shown in , and which includes a runner portion, a support structure or stem portion 25, a plurality of runner portions or branch portions 27 attached to and extending from the stem portion, and a plurality of branch portions attached to the stem portion At least one cutting blade 23 for each branch portion. The stem portion 25 has a longitudinal axis extending between a top end 29 and a bottom end 31 of the stem portion, and at least one of the top end and the bottom end of the stem portion is arranged above and above a respective uppermost portion 33 of each cutting blade 23, respectively. Below the lowermost part 35 . In other words, there is at least one of: (A) the top end 29 of the stem portion 25 is arranged above the uppermost portion 33 of each cutting insert 23 along the longitudinal axis and (B) the bottom end 31 of the stem portion along the The longitudinal axis is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com