Spraying cavity and steam cavity integrated phase change cooling device and system

A technology of phase change cooling and spray chamber, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. It can solve the problems of limiting spray cooling heat transfer capacity, spray wall drying up, etc., and achieves good temperature uniformity Performance, the effect of improving high efficiency and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

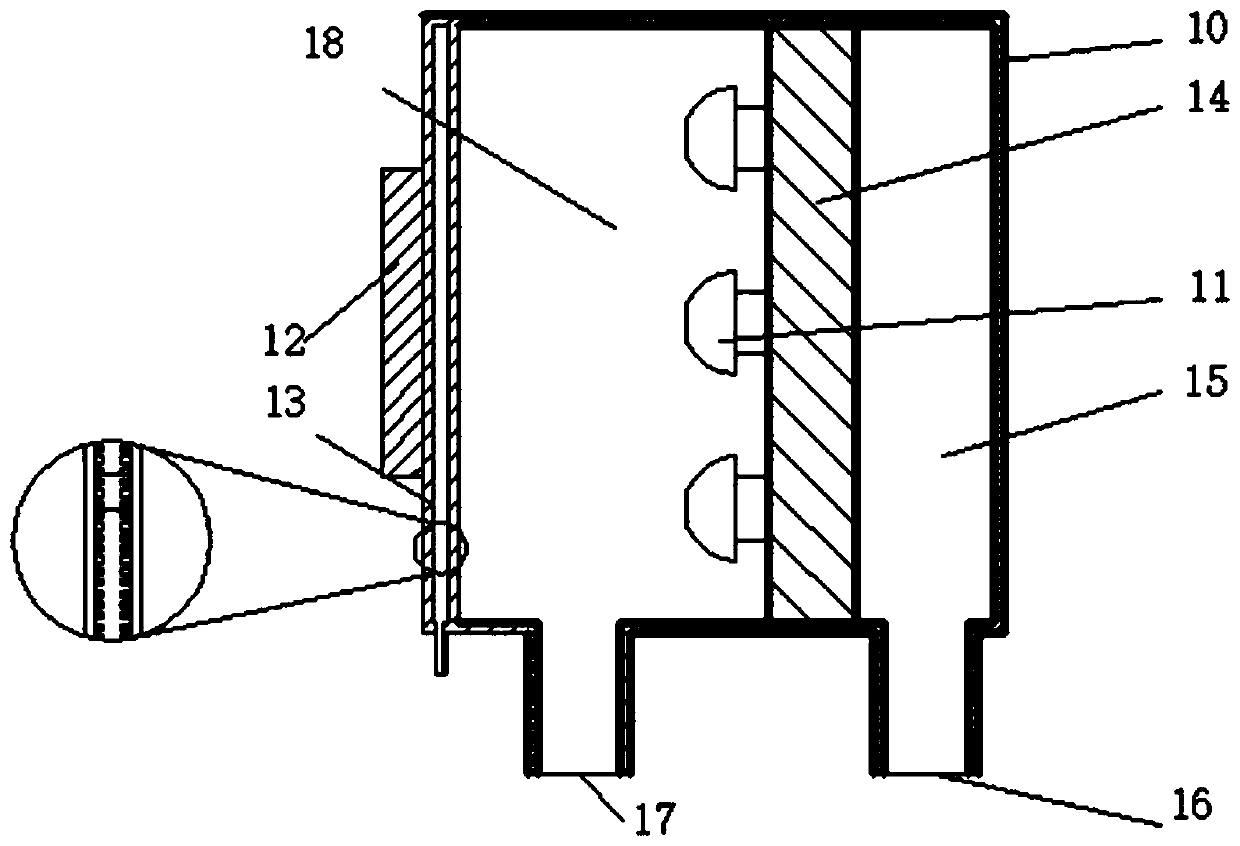

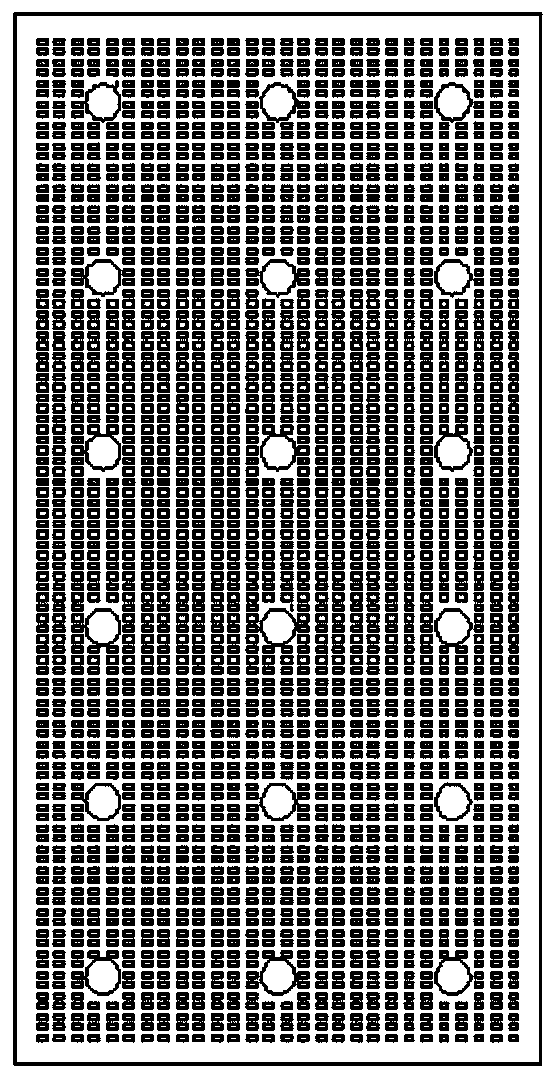

[0021] see figure 1 , a spray chamber and steam chamber integrated phase change cooling device, including a chamber body 10, a spray chamber liquid inlet pipe 16, a spray chamber liquid outlet pipe 17, and an orifice plate 14 and an array nozzle 11 located in the chamber body 10 , the cavity 10 includes a spray chamber and a steam chamber 13, the steam chamber 13 is integrally connected with the spray chamber, has no contact thermal resistance, high thermal conductivity, and the steam chamber 13 can expand the heat generated by the electronic component 12 to the entire spray surface, The orifice plate 14 divides the spray chamber into a buffer chamber 15 and a spray chamber 18, the spray chamber inlet pipe 16 communicates with the buffer chamber 15, and the spray chamber outlet pipe 17 communicates with the spray chamber 18 , the array nozzle 11 is arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com