Surface modified current collector and preparation method and application thereof

A surface modification and current collector technology, which is applied in electrode collector coating, electrode manufacturing, electrode carrier/collector, etc., can solve problems such as reducing the mechanical strength of current collectors, damage to the surface of current collectors, and affecting battery life. , to achieve the effect of improving electron collection ability, enhancing surface activity and increasing effective contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] One aspect of the embodiments of the present invention provides a method for preparing a surface-modified current collector, which includes:

[0033] provide a substrate;

[0034] Using magnetron sputtering technology to deposit and form MoS on the surface of the substrate 2 / metal composite film to obtain a surface-modified current collector, the MoS 2 / metal composite film including MoS 2 / Ag composite film, MoS 2 / Ti composite film and MoS 2 / Pb composite film, etc., or a combination of two or more, but not limited thereto.

[0035] In some embodiments, the preparation method includes: using magnetron sputtering technology, MoS 2 The target and the metal target are used as the target material, and the protective gas is used as the working gas, and a negative bias is applied to the substrate, and the MoS 2 The target and the metal target apply a target current to deposit and form MoS on the surface of the substrate 2 / metal composite film.

[0036] Further, ...

Embodiment 1

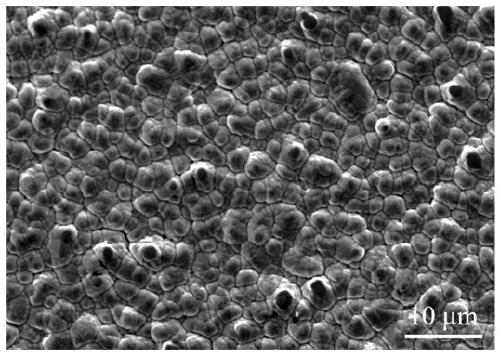

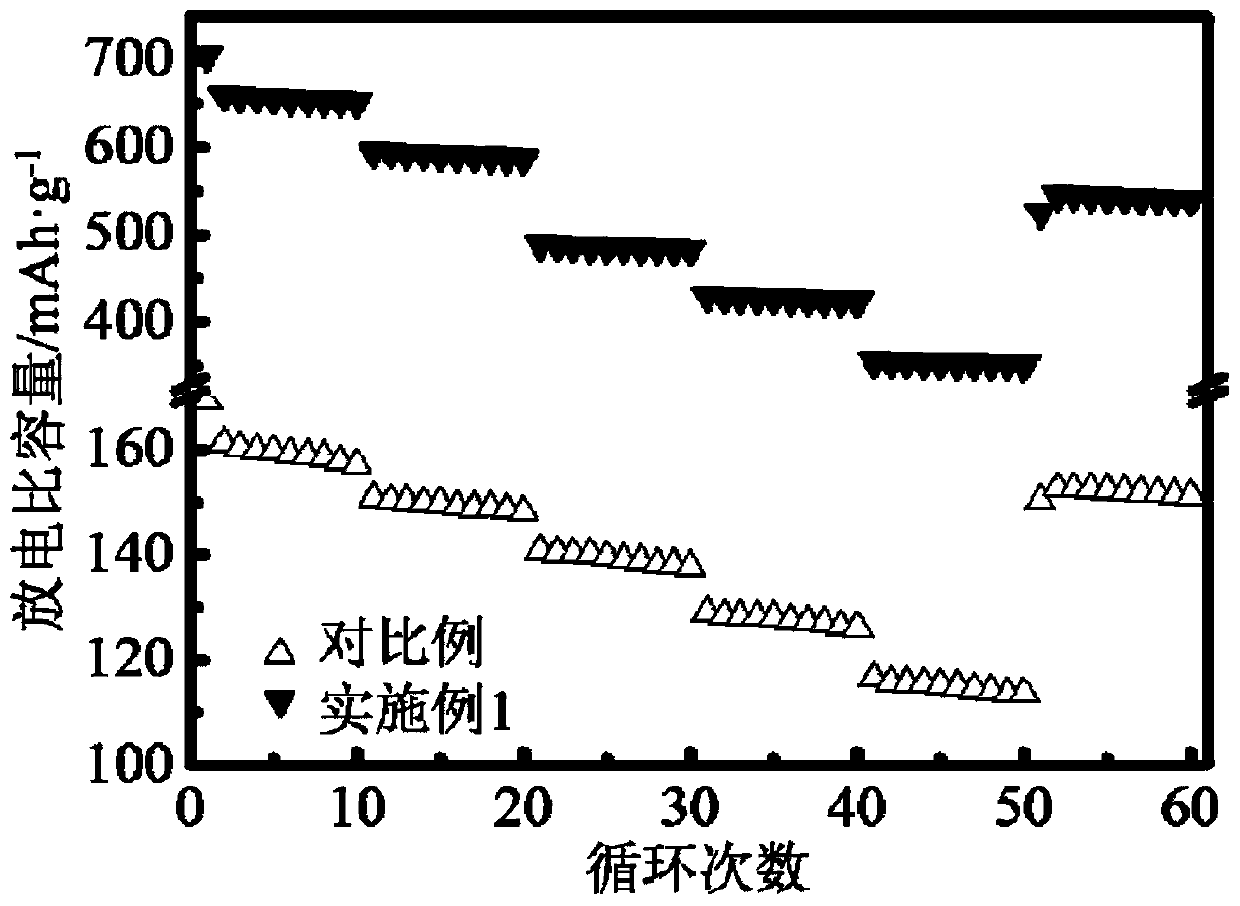

[0056] A copper current collector for negative electrodes of lithium-ion batteries, using magnetron sputtering to modify MoS on the surface of copper foil 2 / Ag composite film. The method for preparing a copper current collector for a negative electrode of a lithium ion battery comprises the following steps:

[0057] (1) Cleaning: the size is 13.5×30cm 2 , the copper foil with a thickness of 9 μm was wiped flat with ethanol and then blown dry with dry nitrogen;

[0058] (2) Sample loading: Put the processed copper foil into the vacuum chamber of the multifunctional magnetron sputtering equipment and fix it, and pre-evacuate the vacuum chamber to 3.0×10 -5 Pa;

[0059] (3) Pre-sputtering: Start the magnetron sputtering pre-sputtering program to remove the oxide layer on the surface of the copper foil to improve the bonding force between the copper foil and the deposited material;

[0060] (4) Deposition: Start the magnetron sputtering deposition program and turn on MoS 2 t...

Embodiment 2

[0064] A copper current collector for negative electrodes of lithium-ion batteries, using magnetron sputtering to modify MoS on the surface of copper foil 2 / Ti composite film. The method for preparing a copper current collector for a negative electrode of a lithium ion battery comprises the following steps:

[0065] (1) Cleaning: the size is 13.5×30cm 2 , the copper foil with a thickness of 11 μm was wiped flat with ethanol and then blown dry with dry nitrogen;

[0066] (2) Sample loading: Put the processed copper foil into the vacuum chamber of the multifunctional magnetron sputtering equipment and fix it, and pre-evacuate the vacuum chamber to 5.0×10 -4 Pa;

[0067] (3) Pre-sputtering: Start the magnetron sputtering pre-sputtering program to remove the oxide layer on the surface of the copper foil to improve the bonding force between the copper foil and the deposited material;

[0068] (4) Deposition: Start the magnetron sputtering deposition program and turn on MoS 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com