Accident resistant rod-shaped nuclear fuel element and preparation method thereof

A nuclear fuel element and rod-shaped technology, which is applied in the field of nuclear power, can solve problems such as hindering the export of fuel pellet heat, and achieve the effects of eliminating gaps, increasing uranium loading, and good thermal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

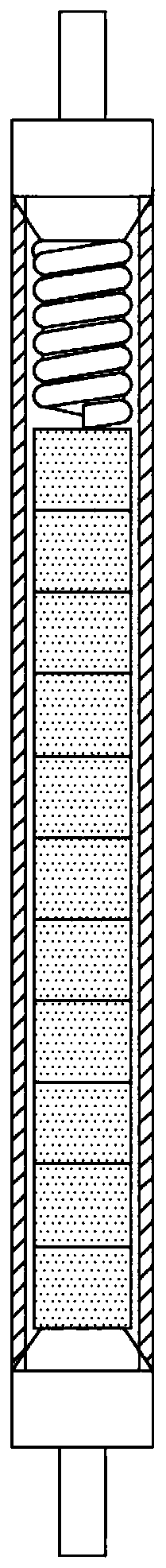

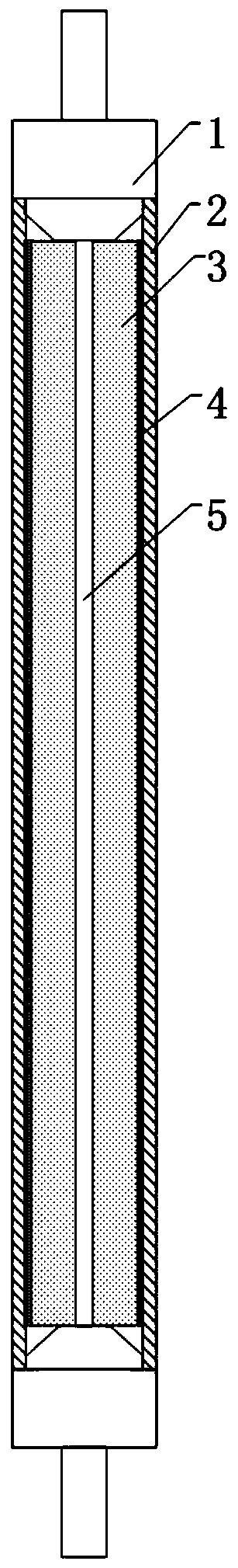

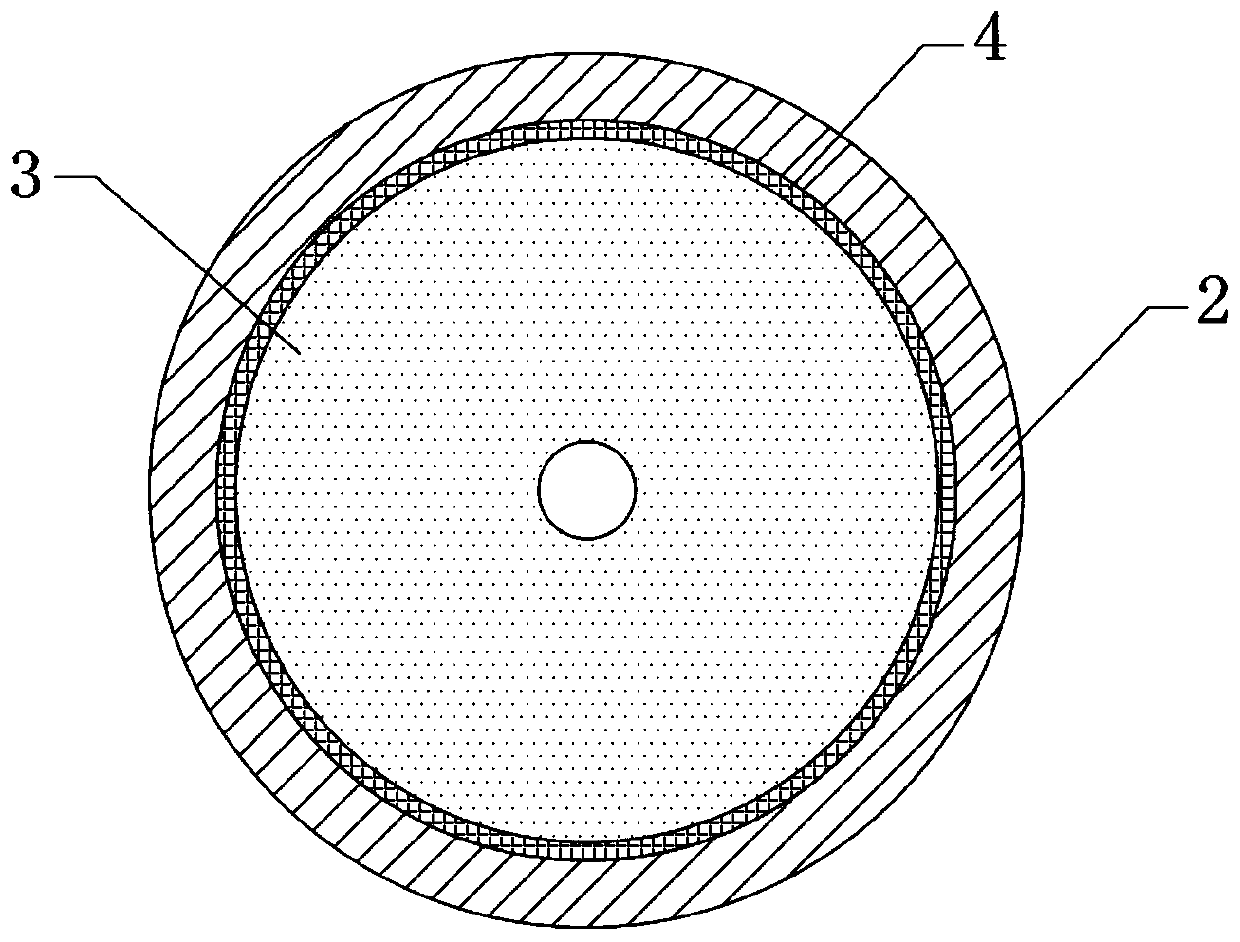

[0032] refer to Figure 1-4 , an accident-resistant rod-shaped nuclear fuel element, including two end plugs 1, a stainless steel cladding 2 is installed between the two end plugs 1, and a U 3 Si 2 Core 3, and U 3 Si 2 The core 3 is located between the two end plugs 1, the U 3 Si 2 There is a middle hole 5 inside the core body 3, and the U 3 Si 2 Between the core body 3 and the stainless steel cladding 2 is a metallurgical bonding layer 4, and the thickness of the metallurgical bonding layer 4 is not greater than 0.2 mm.

[0033] refer to Figure 5 , a method for preparing an accident-resistant rod-shaped nuclear fuel element, comprising the following steps:

[0034] S1. Prepare U 3 Si 2 Base Ingot: Enrichment of U with Nuclear Grade 235 Metal powder and nuclear-grade pure Si powder are mixed evenly and pressed into blocks, melted in an electric arc furnace, and annealed at 800°C to prepare U 3 Si 2 Ingot;

[0035] S2, prepare U 3 Si 2 Core 3: use U 3 Si 2The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com