Rod-shaped nuclear fuel element based on 3D printing and sealing forming method thereof

A nuclear fuel element, 3D printing technology, applied in the field of nuclear power, can solve problems such as poor sealing performance of cladding and end plugs, and achieve the effect of increasing uranium loading, ensuring accuracy, and ensuring sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

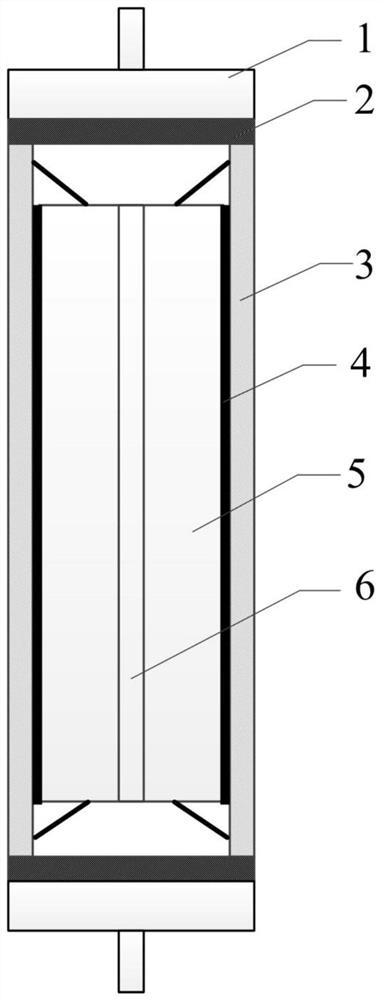

[0016] A 3D printing sealing forming method for a rod-shaped nuclear fuel element, comprising the following steps:

[0017] 1) Mix short carbon fibers with a particle size of 100 μm, 40 μm, 20 μm and 5 μm at a mass ratio of 2:4:1.5:2.5, and the length of the short carbon fibers is 5 to 10 μm to obtain fiber powder for 3D printing. The configured carbon fiber powder Mix with photosensitive resin adhesive in a mass ratio of 1:3 to obtain 3D printing ink;

[0018] 2) Establish a three-dimensional CAD model of the cladding sealing ring, establish the movement trajectory of the rod-shaped nuclear fuel element, and match it with the scanning path. The movement trajectory of the rod-shaped nuclear fuel element rotates around the center hole 6, and the scanning path revolves around the rod-shaped nuclear fuel element. 3D printer The nozzle remains stationary.

[0019] 3) Import the production data of the cladding sealing ring into a 3D printer, and use the printing ink prepared in st...

Embodiment 2

[0023] A 3D printing sealing forming method for a rod-shaped nuclear fuel element, comprising the following steps:

[0024] 1) Mix short carbon fibers with a particle size of 100 μm, 40 μm, 20 μm and 5 μm at a mass ratio of 2:4:1.5:2.5, and the length of the short carbon fibers is 5 to 10 μm to obtain fiber powder for 3D printing. The configured carbon fiber powder Mix with photosensitive resin adhesive in a mass ratio of 1:2.5 to obtain 3D printing ink;

[0025] 2) Establish a three-dimensional CAD model of the cladding sealing ring, establish the movement trajectory of the rod-shaped nuclear fuel element, and match it with the scanning path. The movement trajectory of the rod-shaped nuclear fuel element rotates around the center hole 6, and the scanning path revolves around the rod-shaped nuclear fuel element. 3D printer The nozzle remains stationary.

[0026] 3) Import the production data of the cladding sealing ring into a 3D printer, and use the printing ink prepared in ...

Embodiment 3

[0031] A 3D printing sealing forming method for a rod-shaped nuclear fuel element, comprising the following steps:

[0032] 1) Mix short carbon fibers with a particle size of 100 μm, 40 μm, 20 μm and 5 μm at a mass ratio of 2:4:1.5:2.5, and the length of the short carbon fibers is 5 to 10 μm to obtain fiber powder for 3D printing. The configured carbon fiber powder Mix with photosensitive resin adhesive in a mass ratio of 1:4 to obtain 3D printing ink;

[0033] 2) Establish a three-dimensional CAD model of the cladding sealing ring, establish the movement trajectory of the rod-shaped nuclear fuel element, and match it with the scanning path. The movement trajectory of the rod-shaped nuclear fuel element rotates around the center hole 6, and the scanning path revolves around the rod-shaped nuclear fuel element. 3D printer The nozzle remains stationary.

[0034] 3) Import the production data of the cladding sealing ring into a 3D printer, and use the printing ink prepared in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com