Kitchen fume purification system for building flue and control method of kitchen fume purification system for building fuel

A technology of oil fume purification and flue, which is applied in the direction of oil fume removal, heating methods, household heating, etc. It can solve the problems of inability to adjust the oil fume purifier, large exhaust resistance, and large energy consumption, and achieve good smoke exhaust and purification effects , good purification effect and high system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

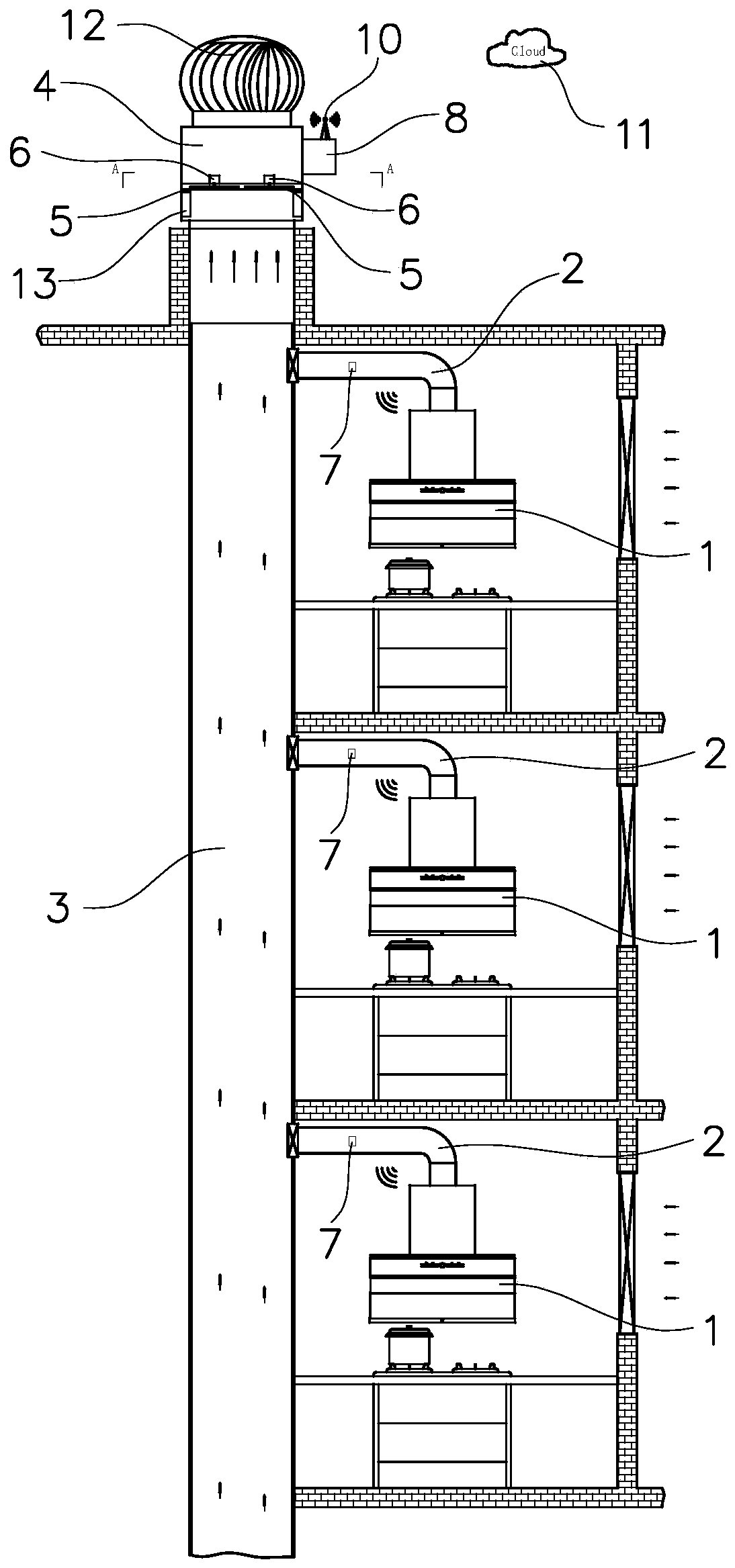

[0034] Such as Figure 1 to Figure 3 As shown, the cooking fume purification system of the building flue kitchen in this embodiment includes range hoods 1 installed on different floors, and the air outlets of each range hood 1 are communicated with the public flue 3 through their respective smoke pipes 2. A range hood 1 has an indoor unit controller 7 , and in this embodiment, the indoor unit controller 7 is installed on the smoke pipe 2 .

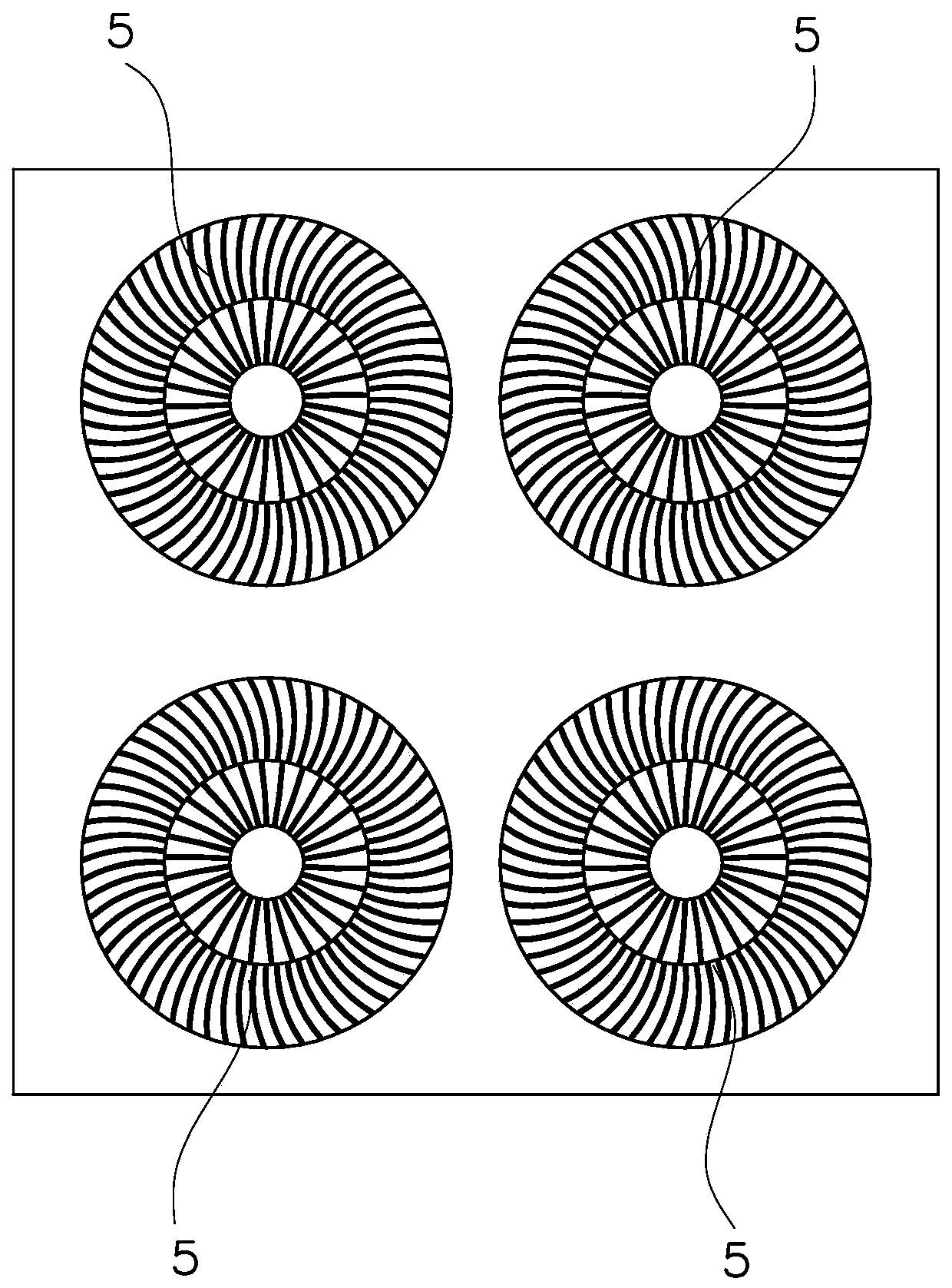

[0035] On the roof, there is an air outlet channel 4 connected to the outlet of the common flue 3, and a rotary filter screen 5 and a motor 6 that drives the rotary filter screen to rotate are installed in the air outlet channel 4, and the rotary filter screen 5 is located below the motor 6 And facing the air outlet of public flue 3. In this embodiment, there are four rotary filter screens 5 and they are independently driven by their respective motors 6 . After the system works, oil will remain on the rotary filter screen 5. In this embo...

Embodiment 2

[0046] Such as Figure 4 and Figure 5 As shown, the oil fume purification system of this embodiment is also equipped with a wind pressure sensor 9 in the air outlet channel 4, and the rest of the structure is the same as that of the first embodiment, and will not be described here.

[0047] After the wind pressure sensor 9 is installed, the main controller 8 can control the speed of the motor 6 accordingly by reading the output wind pressure value of the wind pressure sensor 9 .

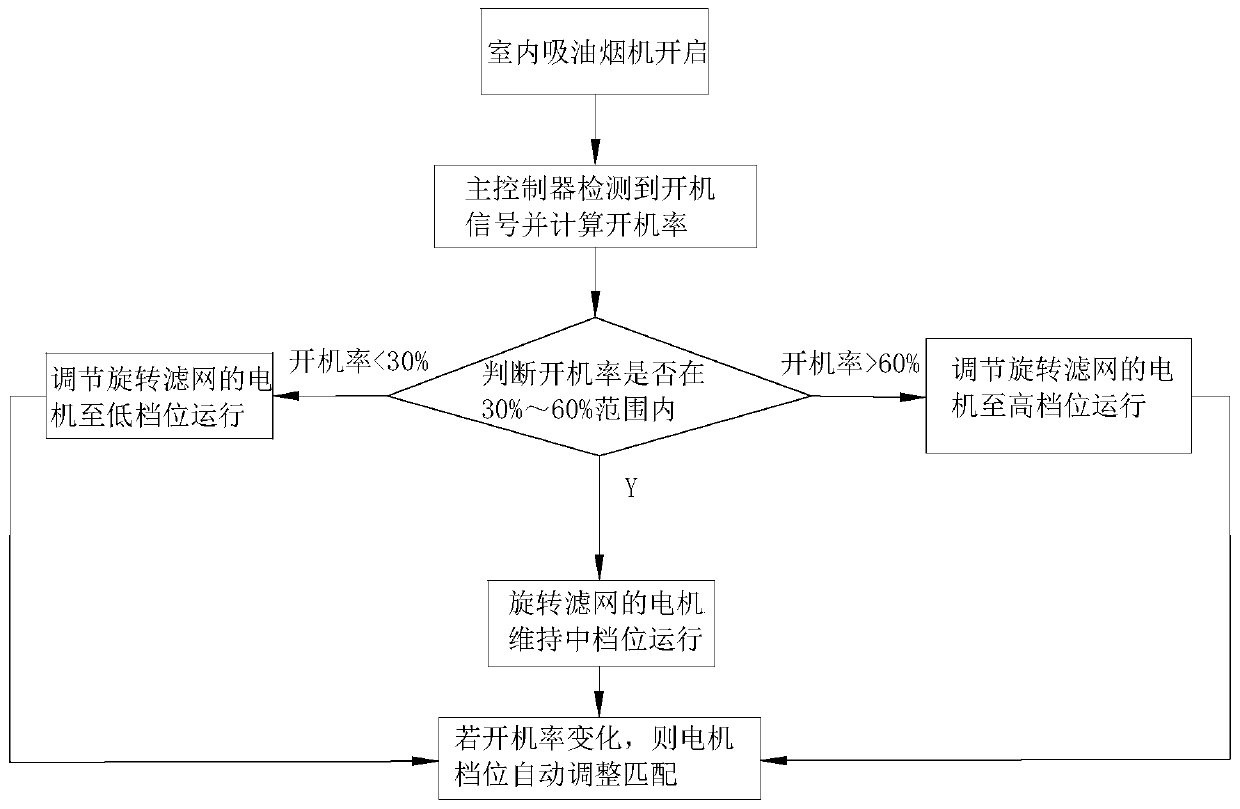

[0048] The control method of the oil fume purification system includes the following steps:

[0049] ①, range hood 1 is turned on;

[0050] ②. Wind pressure sensor 9 detects changes in wind pressure at the outlet of public flue 3;

[0051] ③, the main controller 8 reads the output wind pressure value P of the wind pressure sensor 9, and compares it with the preset threshold range [P1, P2],

[0052]If P≥P2, then adjust the motor 6 to run at a high gear;

[0053] If P1≤P

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com