Oil-containing sludge incineration system for pressurized fluidized bed and incineration treatment method

A pressurized fluidized bed, sludge incineration technology, applied in the combustion method, incinerator, combustion type and other directions, can solve the problems of high equipment investment and operating costs, small equipment processing capacity, large floor space, etc., to reduce The effect of equipment investment and operation investment, improving processing capacity and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

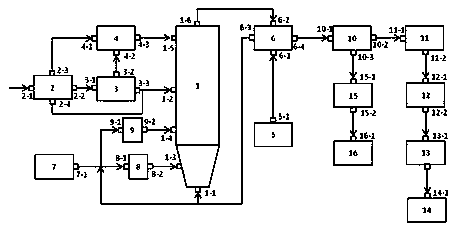

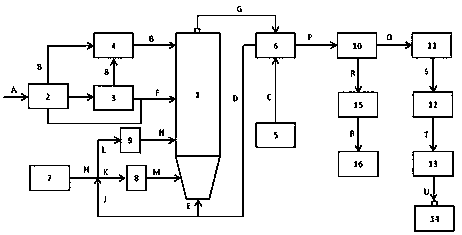

[0086] to combine figure 1 , 2 As shown, the oily sludge with low calorific value is used as raw material, the water content is 85%, the calorific value is 1500kcal / kg, and the sludge treatment capacity is 9 t / h.

[0087] The oily sludge incineration process is as follows:

[0088] 1) The oily sludge raw material A from the source of oily sludge is loaded into the sludge receiving system 2, and then transported to the sludge tank storage system 3 for storage. The odor B volatilized by the system 3 is collected by the odor collection / pressurization system 4 and discharged from the odor collection / pressurization system 4;

[0089] 2) 20000 Nm generated by the pressurized combustion air supply system 5 3 The low-temperature pressurized air C at 25°C and 0.3 MPa / h enters the pressurized combustion air preheating system 6, and the 850°C, 0.3 MPa, nitrogen oxide content from the fluidized bed incinerator (incinerator for short) 1 Exchange heat for 820 ppm high-temperature pressu...

Embodiment 2

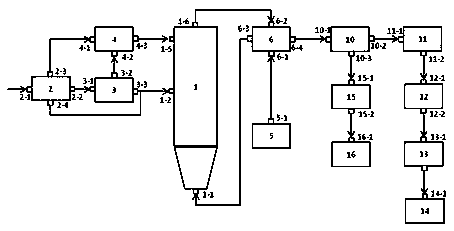

[0102] In this example, the oily sludge with high heat value is used as raw material, the water content is 70%, the heat value is 3000 kcal / kg, and the sludge treatment capacity is 5 t / h, so the fuel supply system is not included in Example 2 7. The first burner 8, the second burner 9, combined image 3 , 4 Shown:

[0103] The oily sludge incineration process is as follows:

[0104] 1) The oily sludge raw material A from the source of oily sludge is loaded into the sludge receiving system 2, and then transported to the sludge tank storage system 3 for storage. The odor B volatilized by the system 3 is collected by the odor collection / pressurization system 4 and discharged from the odor collection / pressurization system 4, and the discharged odor B enters the incinerator 1 for incineration (after the incinerator starts);

[0105] 2) 20000 Nm generated by the pressurized combustion air supply system 5 3 The pressurized air C at 25°C and 0.5 MPa / h enters the pressurized combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com