Commercial vehicle disc brake caliper assembly

A disc brake, commercial vehicle technology, applied to the type of brake, the brake in the axial direction, the components of the brake, etc., can solve the problems of brake deformation or damage, heat can not be dissipated, affecting the rolling of steel balls, etc., to improve the durability. Abrasion and stability, improve waterproof and dustproof function, increase the effect of sliding stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

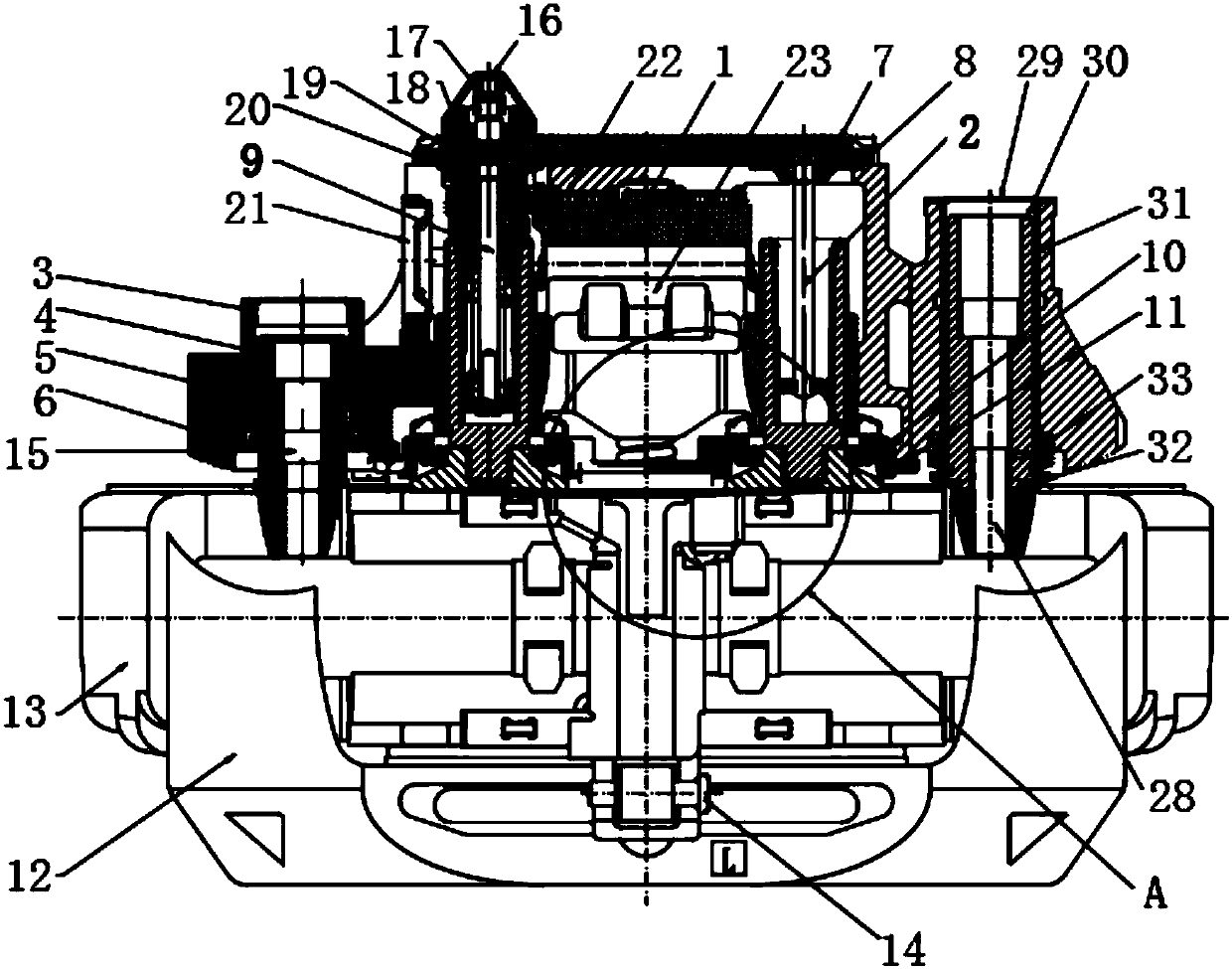

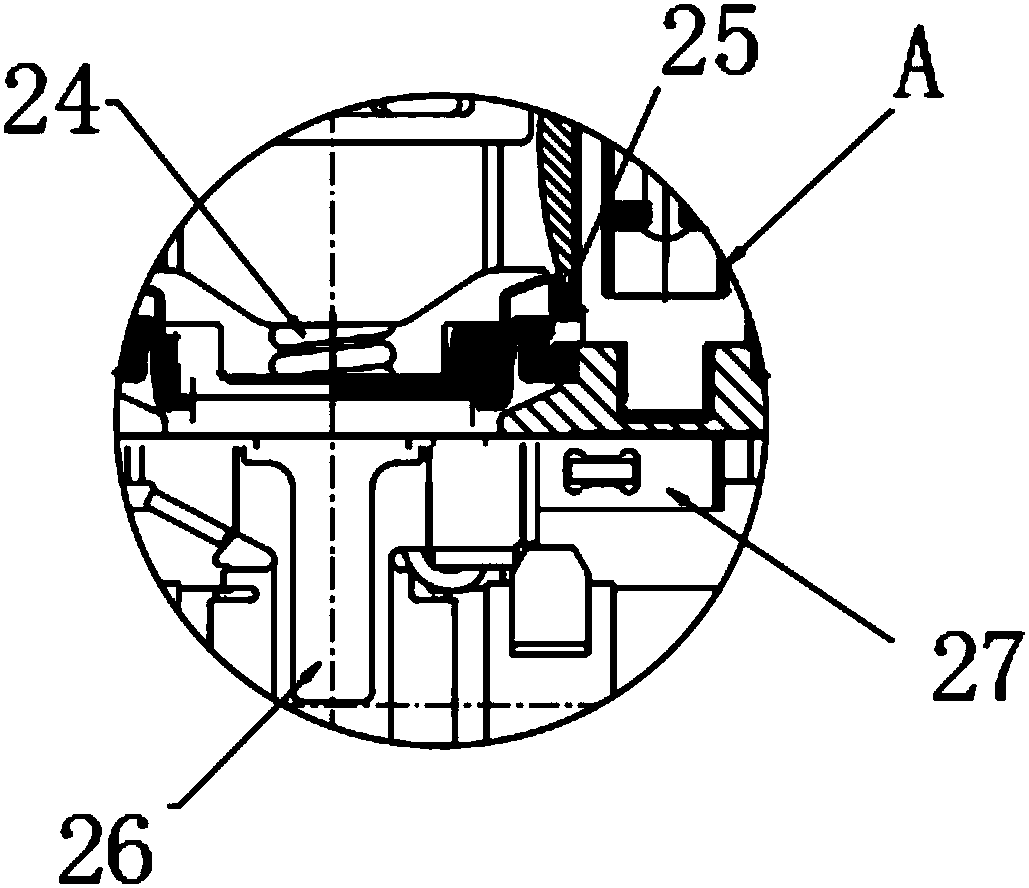

[0074] Such as Figure 1 to Figure 31 As shown, this embodiment provides a commercial vehicle disc brake caliper assembly, which mainly includes the following parts:

[0075] Brake caliper body 12, the outside of brake caliper body 12 is equipped with brake bracket 13, the inside is equipped with pin shaft 14 and the first hexagon socket head cap screw 26, and the ends of brake caliper body 12 sides are respectively installed There are left guide pin parts and right guide pin parts;

[0076] The main adjuster assembly 9 adopts a brake gap adjuster structure with gear clutch anti-overload function;

[0077] The driven adjuster assembly 2 adopts a circlip structure;

[0078] Wherein, the main adjuster assembly 9 and the driven adjuster assembly 2 are located between the left guide pin part and the right guide pin part, and the top of the main adjuster assembly 9 and the top of the driven adjuster assembly 2 pass through the sprocket chain mechanism Connection, the bottom of t...

Embodiment 2

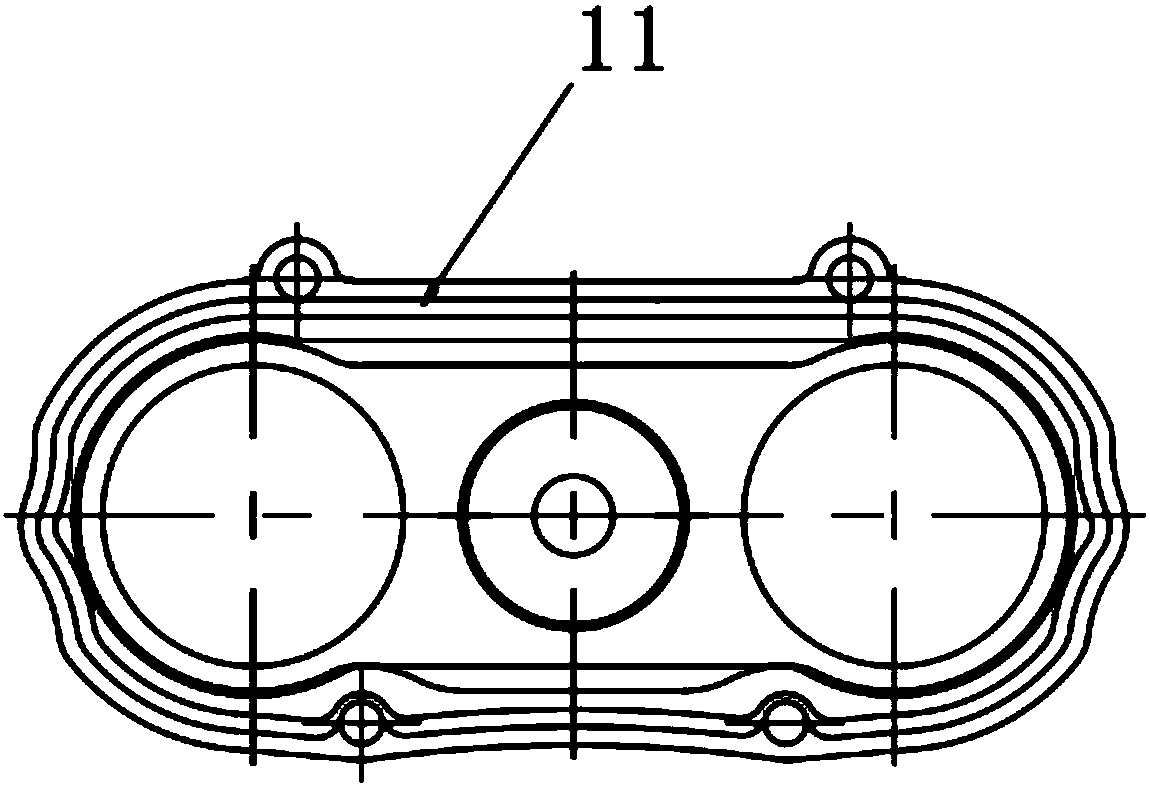

[0088]A commercial vehicle disc brake caliper body assembly, the structure of which is as described in Embodiment 1, the difference is that the height of the short bush 4 is 35 mm. According to the actual processing situation, the maximum height of the short bush can be selected as 35mm, and the height exceeding 35mm is difficult to meet the matching and installation requirements of the caliper assembly.

Embodiment 3

[0090] A commercial vehicle disc brake caliper body assembly, the structure of which is as described in Embodiment 1, the difference is that the height of the short bush 4 is 30 mm. The short bushing with a height of 30mm is not long or short, and the height is just right. It can not only increase the sliding stroke of the short pin, but also ensure the wear resistance and better guidance of the short bushing, and it is more convenient for machining.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com