Compatilizer and preparation method and application thereof

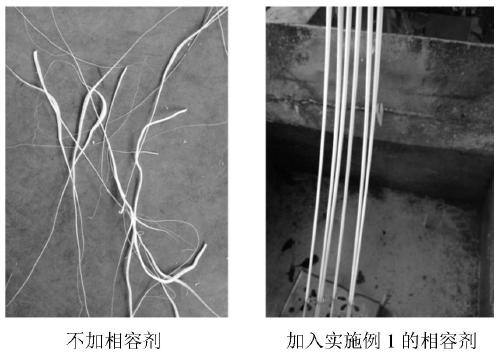

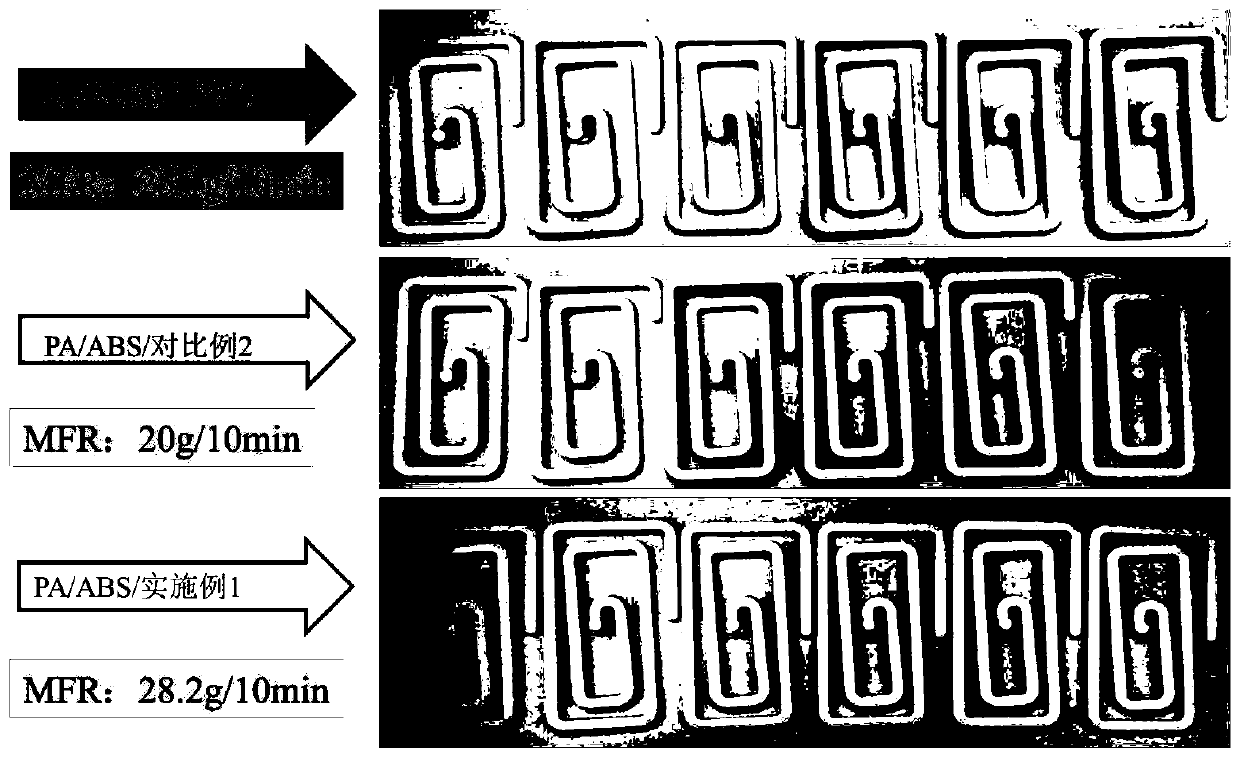

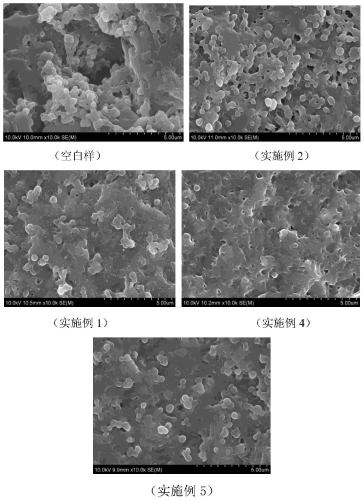

A technology of compatibilizer and styrene resin, which is applied in the field of polymers, can solve the problems of insufficient toughness improvement, too much reduction in rigidity and modulus, etc., and achieve the effects of low residue, improved grafting efficiency, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~6

[0032] Said embodiment weighs raw materials according to the following components in percentage by weight (concrete component distribution ratio is shown in Table 1):

[0033]

[0034] The specific raw materials used for each component can be: ABS and SAN are selected for styrene resin; POE (ethylene octene copolymer) and EPDM (ethylene-propylene-norbornene copolymer) are selected for vinyl elastomer; Nano-structure slow-release peroxide trigger system and conventional trigger system compound; antioxidant 168; lubricant TAF; functional monomer GAM, MAH.

[0035] Put the above raw materials into the high mixer according to the proportion and mix them for 3-5 minutes, discharge the materials, and feed them into the twin-screw extruder, 0.5-5% of functional monomers and 0.1-5% of conventional initiators are respectively used for side feeding Feed by way of feeding, and then carry out free radical deactivation treatment by ultrasonic in the post-reaction stage, and then extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com