Preparation method for preparing anti-hydration magnesia-calcia refractory through phosphate tailing

A technology for refractory materials and phosphorus tailings, which is applied in the field of phosphorus chemical industry, can solve the problems of easy hydration of magnesium-calcium refractories and low utilization rate of phosphorus tailings, and achieves improved hydration resistance, good compressive strength at room temperature, Solve the effect of low utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

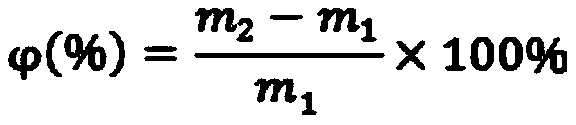

Method used

Image

Examples

Embodiment 1

[0034] Example 1. A method for preparing hydration-resistant magnesia-calcium refractory materials using phosphorus tailings, which is prepared according to the following steps;

[0035] A. Dry the phosphorus tailings at 100°C for 22 hours, crush, grind, pass through a 100-mesh sieve, and perform pre-calcination. The heating rate of the pre-calcination is 8°C / min. Take it out at room temperature, grind it, and pass through a 40-mesh sieve to obtain pre-calcined phosphorus tailings;

[0036] B. Mix 100kg of pre-calcined phosphorus tailings, 1kg of nano-titanium dioxide, 1kg of nano-zirconia and 7kg of binder evenly, molding at a molding pressure of 90Mpa, loading temperature of 100°C, and drying time of 10h. After drying Naturally cool to room temperature, calcined, the calcined temperature is 1500°C, and the calcined time is 2h to obtain the finished product.

Embodiment 2

[0037] Example 2. A method for preparing hydration-resistant magnesia-calcium refractory materials using phosphorus tailings, which is prepared according to the following steps;

[0038] A. Dry the phosphorus tailings at 110°C for 23 hours, crush, grind, pass through a 150-mesh sieve, and perform pre-calcination. The heating rate of the pre-calcination is 9°C / min. Take it out at room temperature, grind it, and pass through a 100-mesh sieve to obtain pre-calcined phosphorus tailings;

[0039] B. Mix 120kg of pre-calcined phosphorus tailings, 2kg of nano-titanium dioxide, 2kg of nano-zirconia and 8kg of binder evenly. The molding pressure is 110Mpa, the loading temperature is 120°C, and the drying time is 11h. After drying Naturally cool to room temperature, calcined, the calcined temperature is 1550°C, and the calcined time is 2h to obtain the finished product.

Embodiment 3

[0040] Example 3. A method for preparing hydration-resistant magnesia-calcium refractory materials using phosphorus tailings, which is prepared according to the following steps;

[0041] A. Dry the phosphorus tailings at 110°C for 24 hours, crush, grind, pass through a 200-mesh sieve, and perform pre-calcination. The heating rate of the pre-calcination is 10°C / min. Take it out at room temperature, grind it, and pass through a 150-mesh sieve to obtain pre-calcined phosphorus tailings;

[0042]B. Mix 110kg of pre-calcined phosphorus tailings, 3kg of nano-titanium dioxide, 3kg of nano-zirconia and 9kg of binder evenly, molding at a molding pressure of 90Mpa, loading temperature of 120°C, and drying time of 13h. After drying Naturally cool to room temperature, calcined, the calcined temperature is 1600°C, and the calcined time is 2h to obtain the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com