Micro-clearance assembling device and micro-clearance assembling method for low pressure turbine blade of aircraft engine

A technology of aircraft engines and low-pressure turbines, applied in the field of aircraft engines, can solve the problems of low assembly efficiency and inconvenient operation of the assembly work structure, and achieve the effects of improving the pass rate, flexible and convenient assembly, and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

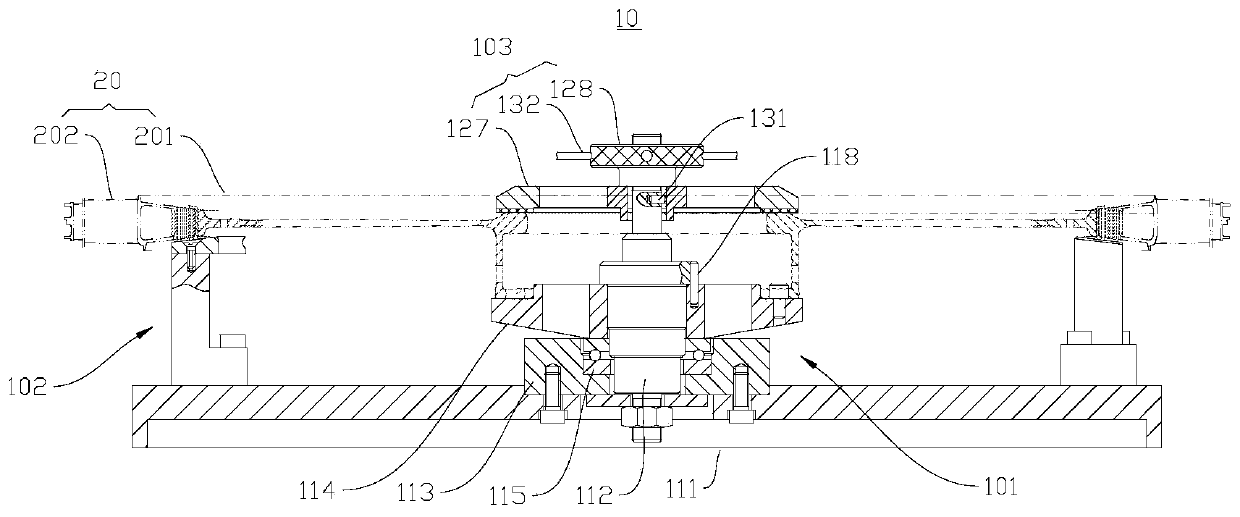

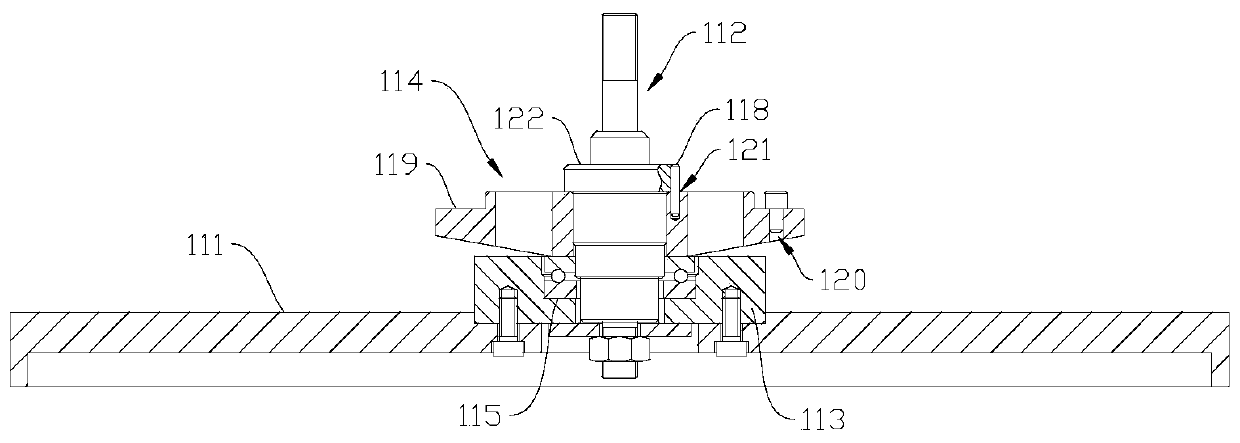

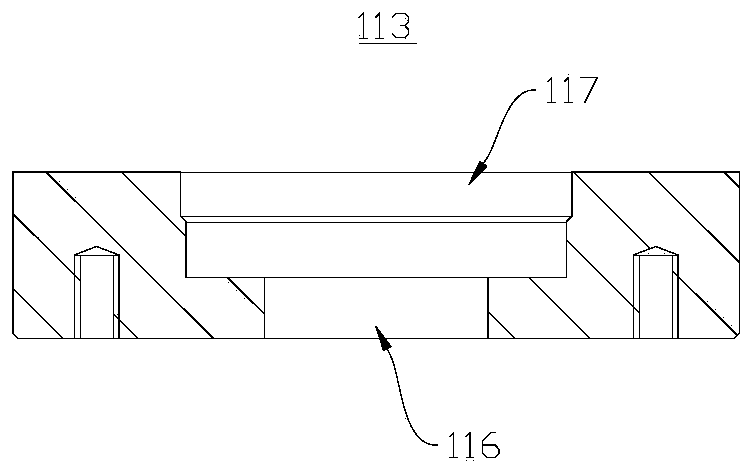

[0039] Please refer to figure 1 , the aircraft engine low-pressure turbine blade micro-gap assembly device 10 of the embodiment of the present invention includes: a bearing assembly 101 , and a support assembly 102 and a pressing assembly 103 respectively arranged on the bearing assembly 101 . figure 1 The middle dotted line part is the turbine 20 , including the turbine rotor 201 and the turbine blades 202 . The bearing assembly 101 is used to rotate the turbine rotor 201 to assemble the turbine blades 202 at different positions, which makes the operation very convenient for workers. The support assembly 102 is used for supporting and positioning the turbine rotor 201 and the turbine blade 202 during the assembly process, which is equivalent to an assembly operation platform. The pressing assembly 103 is used to press and fix the turbine rotor 201 during the assembly process, so as to avoid affecting the assembly accuracy due to the movement of the turbine rotor 201 during t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com