3D printing preparation method for high-strength titanium alloy part of porous structure

A porous structure, 3D printing technology, applied in the field of lightweight porous titanium alloy parts and high strength, to achieve the effect of excellent comprehensive mechanical properties, uniform pores, and avoiding the use of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

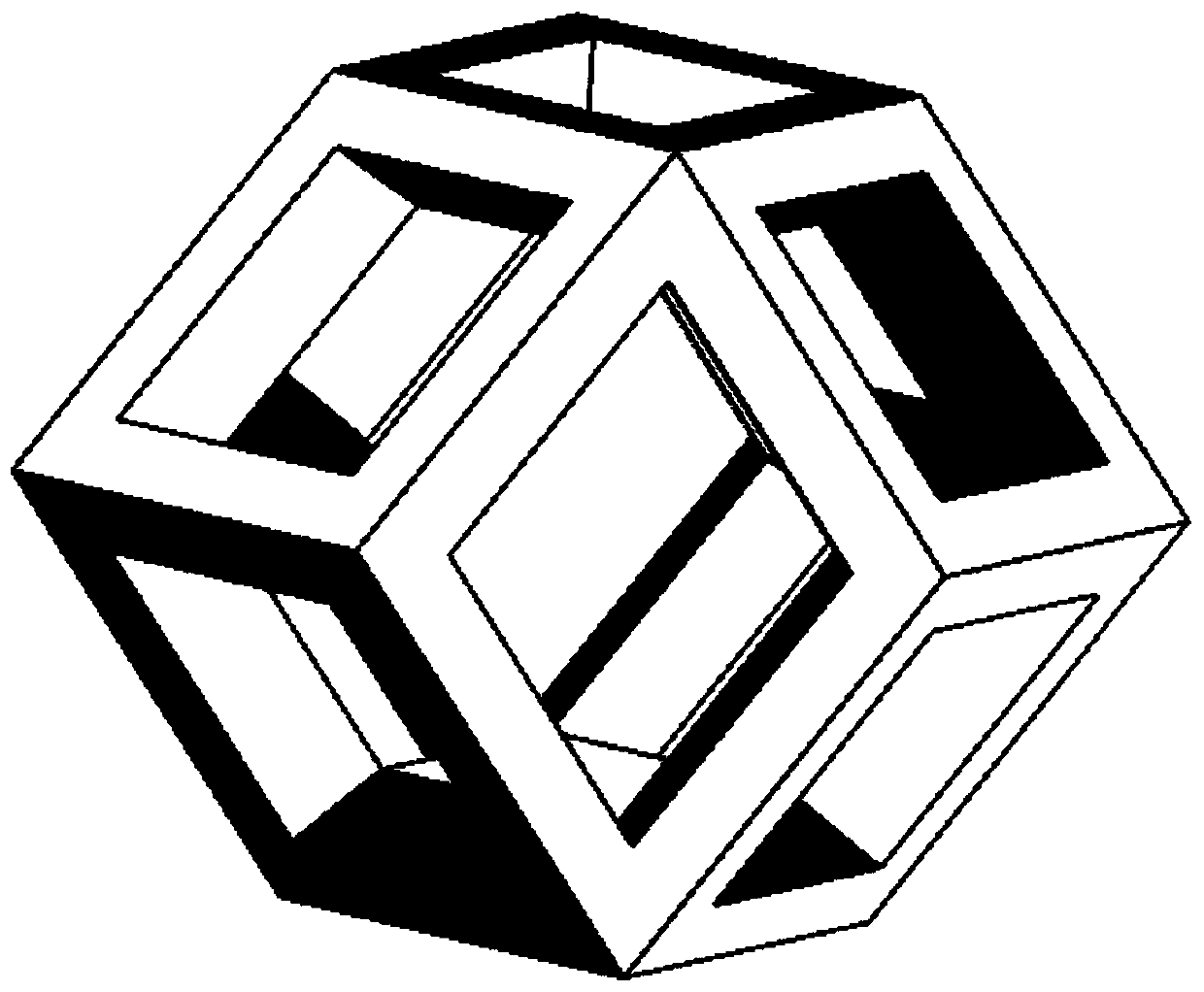

[0017] A 3D printing preparation method for a high-strength porous structure titanium alloy part, the pore structure unit of the porous structure titanium alloy part is as follows figure 1 As shown, the present embodiment is a high-strength porous TC4 titanium alloy material, and the pore structure is composed of basic units in a rhombic dodecahedron structure; each basic unit is composed of 24 cubic titanium alloy columns with the same length. The acute angle between the titanium columns is 70.5 degrees, and the obtuse angle is 109.5 degrees; the length of the titanium columns is 2 mm, and the width and thickness are the same as 0.3 mm. The laser power is 250W, the powder preheating temperature range is 600°C; the scanning speed is 500mm / s; the scanning interval is 50μm; the thickness of a single powder layer is 30μm.

Embodiment 2

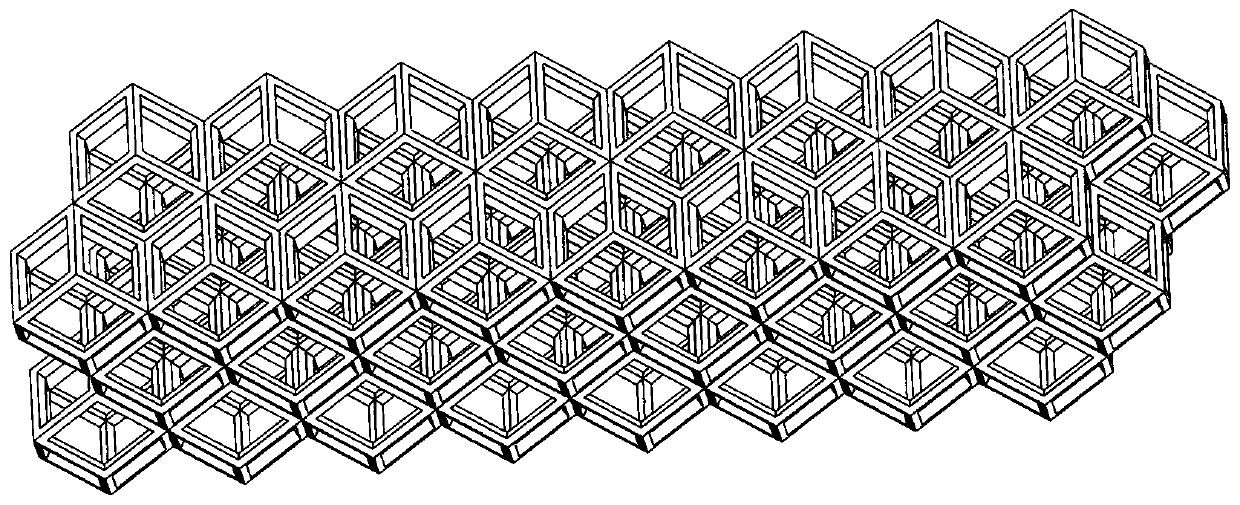

[0019] A 3D printing preparation method for a high-strength porous structure titanium alloy part, the pore structure unit of the porous structure titanium alloy part is as follows figure 2 As shown, the present embodiment is a high-strength porous TC4 titanium alloy material, and the pore structure is composed of basic units in a rhombic dodecahedron structure; each basic unit is composed of 24 cubic titanium alloy columns with the same length and 4 The body-diagonal reinforced brackets with different orientations are connected. The acute angle between the titanium columns is 70.5 degrees, and the obtuse angle is 109.5 degrees; the length of the titanium columns is 2 mm, and the width and thickness are the same as 0.3 mm. The reinforcement bracket is a hexagonal titanium alloy column, three of which intersect with the corresponding vertices of the rhombohedral dodecahedral honeycomb section, and the vertices are taken from two different sections; the other intersects with two ...

Embodiment 3

[0021] A 3D printing preparation method for a high-strength porous structure titanium alloy part. This embodiment is high-strength porous pure titanium. The pore structure of the porous structure titanium alloy part is composed of a combination of basic units in a rhombic dodecahedron structure; each basic unit They are all composed of 24 cubic titanium columns with the same length and 4 solid diagonal reinforcement brackets with different orientations. The acute angle between the dodecahedral prisms is 70.5 degrees, and the obtuse angle is 109.5 degrees; the length of the titanium columns is 1mm. The width and thickness are the same as 0.1mm. The reinforcement bracket is also a cubic titanium column, three of which intersect with the corresponding vertices of the rhombohedral dodecahedral honeycomb section, and the vertices are taken from two different sections; the other intersects with two vertices in the vertical direction of the honeycomb section. The laser power is 250W,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com