A forging process of aviation compressor blade based on stainless steel

A technology of stainless steel and air compressors, applied in mechanical equipment, engine components, metal processing equipment, etc., can solve problems such as processing difficulties, reducing the mechanical properties of finished blades, destroying the continuity of metal streamlines, and the surface integrity of finished blades, achieving less Machining allowance, improving product qualification rate and consistency, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A forging process for an aviation compressor blade based on stainless steel, comprising the following steps:

[0073] Step 1, blanking, the stainless steel material is 5CrNiCu17-4, the diameter of the blanking bar is Φ31.75±0.1mm, and the weight is 150±2g;

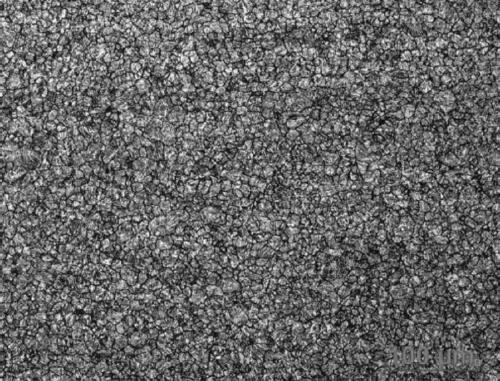

[0074] Step 2. Surface cleaning, using steel sand shot blasting, GH120 purpose steel sand medium, for 30 minutes, to clean the surface of the blanking parts to make the surface clean, and remove the residual coolant and surface defects on the surface of the blanking parts;

[0075] Step 3. Spray the glass lubricant, put the bar into the oven, set the heating temperature to 100°C, and set the heating time to 90 minutes, then take out the bar from the oven, and spray the prepared glass lubricant solution evenly with a spray gun On the surface of the bar, the thickness of the coating is controlled at 0.03mm. Check that the color of the surface coating is uniform and that there is no leakage of the primary color of the ...

Embodiment 2

[0100] A forging process for an aviation compressor blade based on stainless steel, comprising the following steps:

[0101] Step 1, blanking, the stainless steel material is 5CrNiCu17-4, the diameter of the blanking bar is Φ31.75±0.1mm, and the weight is 150±2g;

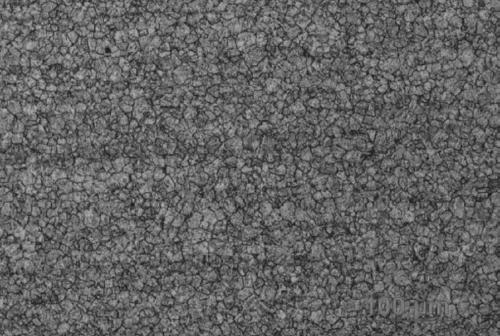

[0102] Step 2. Surface cleaning, using steel sand shot blasting, GH120 purpose steel sand medium, for 30 minutes, to clean the surface of the blanking parts to make the surface clean, and remove the residual coolant and surface defects on the surface of the blanking parts;

[0103] Step 3. Spray the glass lubricant, put the bar into the oven, set the heating temperature to 150°C, and set the heating time to 60 minutes, then take out the bar from the oven, and spray the prepared glass lubricant solution evenly with a spray gun On the surface of the bar, the thickness of the coating is controlled at 0.04mm. Check that the color of the surface coating is uniform and that there is no leakage of the primary color of the ...

Embodiment 3

[0128] A forging process for an aviation compressor blade based on stainless steel, comprising the following steps:

[0129] Step 1, blanking, the stainless steel material is 5CrNiCu17-4, the diameter of the blanking bar is Φ31.75±0.1mm, and the weight is 150±2g;

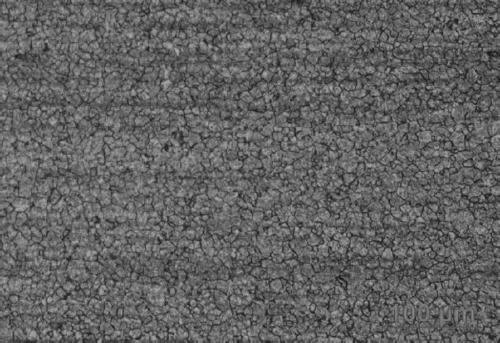

[0130] Step 2. Surface cleaning, using steel sand shot blasting, GH120 purpose steel sand medium, for 30 minutes, to clean the surface of the blanking parts to make the surface clean, and remove the residual coolant and surface defects on the surface of the blanking parts;

[0131] Step 3. Spray the glass lubricant, put the bar into the oven, set the heating temperature to 200°C, and set the heating time to 30 minutes, then take out the bar from the oven, and spray the prepared glass lubricant solution evenly with a spray gun On the surface of the bar, the thickness of the coating is controlled at 0.05mm. Check that the color of the surface coating is uniform and that there is no leakage of the primary color of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com