A Forging Process of Aviation Compressor Blade Based on Nickel-based Superalloy

A nickel-based high-temperature alloy and compressor technology, applied in metal processing equipment, mechanical equipment, engine components, etc., can solve problems such as processing difficulties, destroying the continuity of metal streamlines, the surface integrity of finished blades, and reducing the mechanical properties of finished blades , to achieve less machining allowance, improve product qualification rate and consistency, and achieve good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

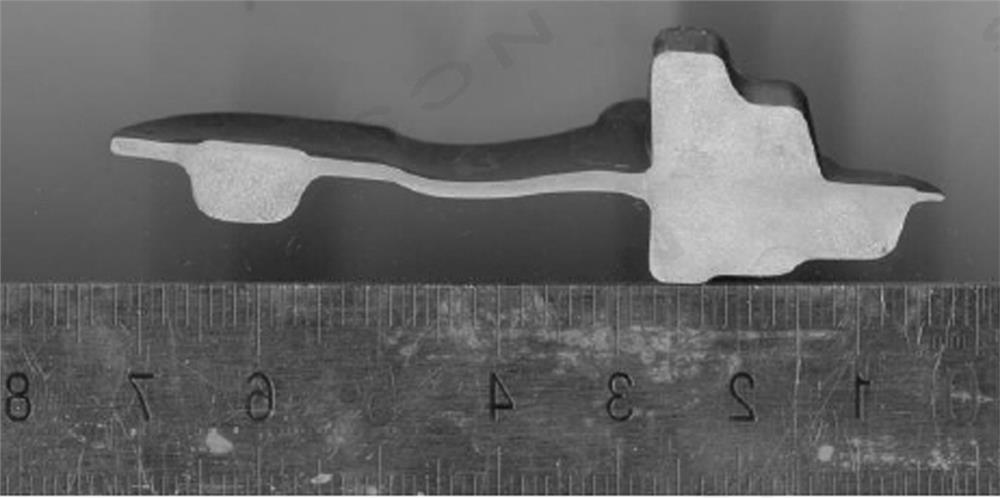

[0091] Taking the continuous production of 200 forgings of the tenth stage rotor blades of an aero-engine compressor in China as an example, the lathe blanking equipment used is an ordinary CNC lathe, the glass lubricant used is a water-based lubricant, and the molding equipment used for extrusion is a 400-ton hydraulic press , The molding equipment used for pre-forging and final forging is a 1000-ton screw press, and the forging heating converter used meets the industry's Class 3 furnace, and the furnace temperature accuracy is ±10°C. Continuously produce 200 pieces of rotor blade forgings, the forging cycle is 1 piece per minute, after passing the first piece confirmation and 3 consecutive pieces of qualified approval, 1 piece will be randomly inspected for every 50 pieces in the process.

[0092] The forging process of the aviation compressor blade based on nickel-based superalloy of the present invention, it comprises the following steps:

[0093] Step 1, blanking, use CNC...

Embodiment 2

[0130] Taking the continuous production of 200 forgings of the tenth stage rotor blades of an aero-engine compressor in China as an example, the lathe blanking equipment used is an ordinary CNC lathe, the glass lubricant used is a water-based lubricant, and the molding equipment used for extrusion is a 400-ton hydraulic press , The molding equipment used for pre-forging and final forging is a 1000-ton screw press, and the forging heating converter used meets the industry's Class 3 furnace, and the furnace temperature accuracy is ±10°C. Continuously produce 200 pieces of rotor blade forgings, the forging cycle is 1 piece per minute, after passing the first piece confirmation and 3 consecutive pieces of qualified approval, 1 piece will be randomly inspected for every 50 pieces in the process.

[0131] The forging process of the aviation compressor blade based on nickel-based superalloy of the present invention, it comprises the following steps:

[0132] Step 1, blanking, use CNC...

Embodiment 3

[0169] Taking the continuous production of 200 forgings of the tenth stage rotor blades of an aero-engine compressor in China as an example, the lathe blanking equipment used is an ordinary CNC lathe, the glass lubricant used is a water-based lubricant, and the molding equipment used for extrusion is a 400-ton hydraulic press , The molding equipment used for pre-forging and final forging is a 1000-ton screw press, and the forging heating converter used meets the industry's Class 3 furnace, and the furnace temperature accuracy is ±10°C. Continuously produce 200 pieces of rotor blade forgings, the forging cycle is 1 piece per minute, after passing the first piece confirmation and 3 consecutive pieces of qualified approval, 1 piece will be randomly inspected for every 50 pieces in the process.

[0170] The forging process of the aviation compressor blade based on nickel-based superalloy of the present invention, it comprises the following steps:

[0171] Step 1, blanking, use CNC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com