A forging process of aero-engine blade based on titanium alloy

An aero-engine, titanium alloy technology, applied in engine components, metal processing equipment, mechanical equipment, etc., can solve the problem of poor product qualification rate and consistency, destroy the surface integrity of the metal streamline continuity, and reduce the mechanical properties of the finished blade. and other problems, to achieve the effect of good consistency, less machining allowance, and improved product qualification rate and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

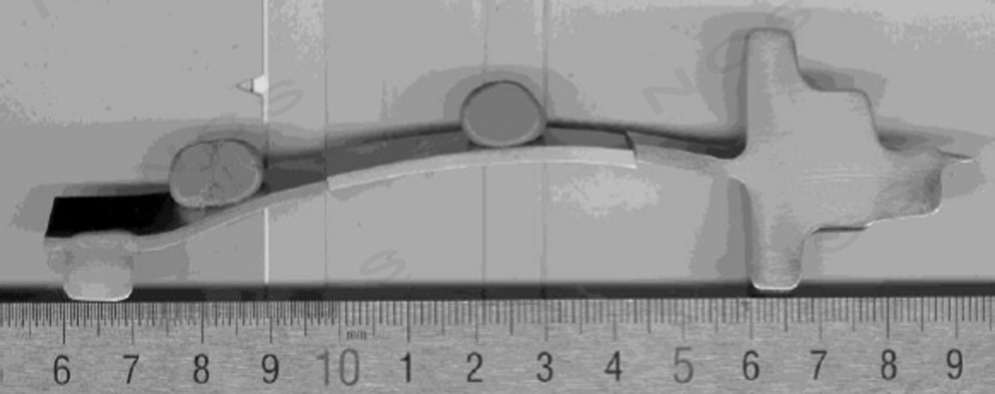

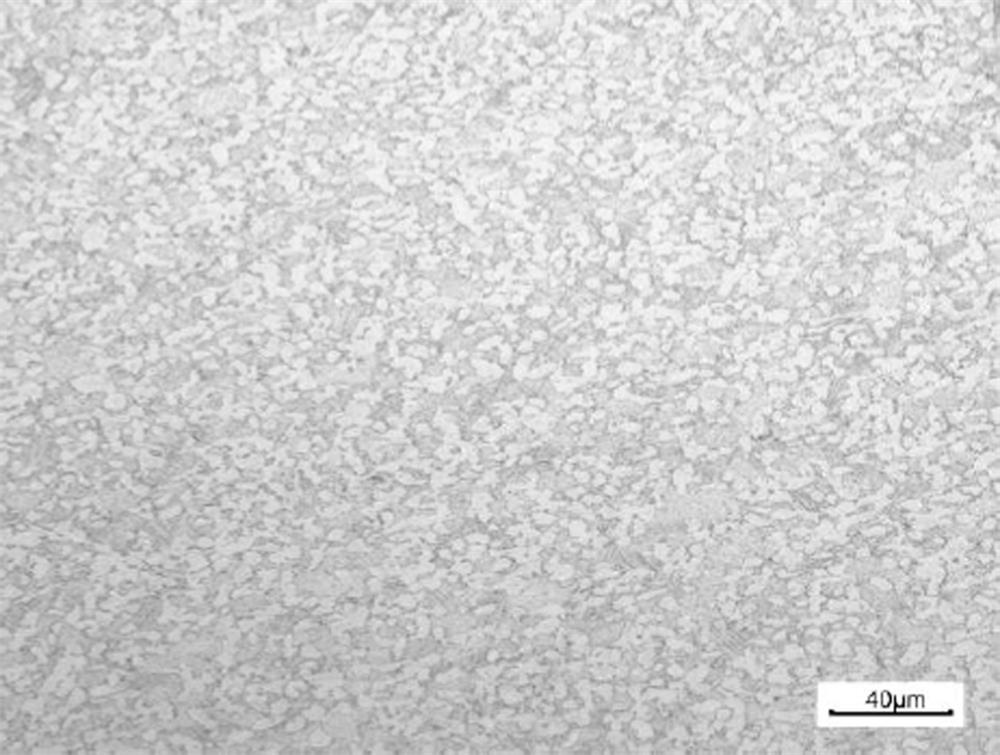

[0084] A forging process for an aero-engine blade based on titanium alloy, comprising the following steps:

[0085] Step (1), blanking, the titanium alloy material is Ti-6Al-4V material, the blanking rod diameter is Φ24.5±0.1mm, and the weight is 120±2g;

[0086] Step (2), surface cleaning, using vibration finishing and acid corrosion, during vibration finishing, put the bar into the vibration finishing machine, the finishing time is 2 hours, the frequency is set to 40Hz, and the height of the abrasive medium is not lower than 10cm below the edge of the finishing machine container, choose ceramic media for the finishing abrasive medium, wash the parts with water after the finishing, and remove the finishing liquid remaining on the surface of the parts; when acid corrosion, the polished rods should be cleaned according to the process requirements Put it into the prepared corrosive solution, clean the surface of the bar through the principle of chemical corrosion, remove the res...

Embodiment 2

[0116] A forging process for an aero-engine blade based on titanium alloy, comprising the following steps:

[0117] Step (1), blanking, the titanium alloy material is Ti-6Al-4V material, the blanking rod diameter is Φ24.5±0.1mm, and the weight is 120±2g;

[0118] Step (2), surface cleaning, using vibration finishing and acid corrosion, during vibration finishing, put the bar into the vibration finishing machine, the finishing time is 2 hours, the frequency is set to 50Hz, and the height of the abrasive medium is not lower than 10cm below the edge of the finishing machine container, choose ceramic media for the finishing abrasive medium, wash the parts with water after the finishing, and remove the finishing liquid remaining on the surface of the parts; when acid corrosion, the polished rods should be cleaned according to the process requirements Put it into the prepared corrosive solution, clean the surface of the bar through the principle of chemical corrosion, remove the res...

Embodiment 3

[0151] A forging process for an aero-engine blade based on titanium alloy, comprising the following steps:

[0152] Step (1), blanking, the titanium alloy material is TC8M-1 material, the blanking rod diameter is Φ18±0.1mm, and the weight is 67±2g;

[0153] Step (2), surface cleaning, using vibration finishing and acid corrosion, during vibration finishing, put the bar into the vibration finishing machine, the finishing time is 2 hours, the frequency is set to 45Hz, and the height of the abrasive medium is not lower than 10cm below the edge of the finishing machine container, choose ceramic media for the finishing abrasive medium, wash the parts with water after the finishing, and remove the finishing liquid remaining on the surface of the parts; when acid corrosion, the polished rods should be cleaned according to the process requirements Put it into the prepared corrosive solution, clean the surface of the bar through the principle of chemical corrosion, remove the residual ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com