Method and device for forming a large-diameter steel pipe bend

A forming method and large-diameter technology, applied in the field of steel pipe manufacturing and processing, can solve the problem that the same large-diameter steel pipe cannot be bent in two different ways

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A kind of large-diameter steel pipe bending forming device

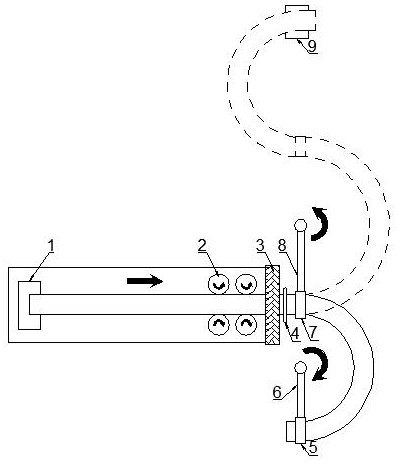

[0027] Such as figure 1 As shown, a large-diameter steel pipe bending forming device provided by the present invention includes a propulsion device 1 for the end of the steel pipe to be bent, a guide wheel 2, an intermediate frequency inductor 3, an induction coil 4, a first chuck 5, and a second chuck The head 7 and the support seat 9; the first chuck 5 and the second chuck 7 are driven to rotate by the first rocker arm 6 and the second rocker arm 8 respectively, and the rotation directions of the first rocker arm 6 and the second rocker arm 8 are opposite. The lengths of the first rocker arm 6 and the second rocker arm 8 are adjusted separately; the first rocker arm 6 drives the first chuck 5 to bend the steel pipe in an arc shape for the first time, and the second rocker arm 8 drives the second chuck 7 pairs The steel pipe is bent in the second arc shape; the support seat 9 is placed on the su...

Embodiment 2

[0028] Embodiment 2 A kind of large-caliber steel pipe bend pipe forming method

[0029] Such as figure 1 As shown, the present invention provides a method for forming large-diameter steel pipe bends, which can bend the same large-diameter steel pipe with two different radii; the embodiment of the present invention is for the material is 12Cr1MoV, the outer diameter D is 325mm, the wall A steel pipe with a thickness t of 30mm is bent with two radii; the bending process includes the following steps in turn: verification before bending, calculation of the size of the bend, installation of the steel pipe, primary bending, secondary bending, and post-bending correction process.

[0030] Verify before bending:

[0031] a. Check the raw material size, the allowable deviation of the outer diameter of the pipe end is -0.5mm~+2.0mm; the difference between the diameter of one end of the steel pipe and the diameter of the other end shall not be greater than 2.0mm;

[0032] b. The ellip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com