Bionic trunk fiber reinforced concrete beam and column structure

A fiber reinforced concrete, beam-column structure technology, applied in the field of concrete beam-column, can solve problems such as unparalleled anti-corrosion and protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

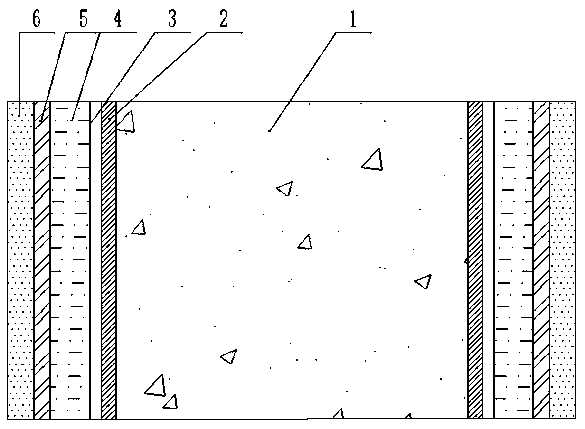

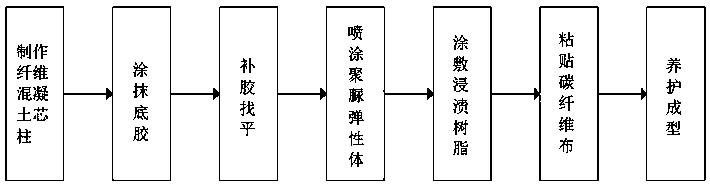

[0029] Such as figure 1 and figure 2 As shown, it is a "carbon fiber-polyurea" double-constrained non-prefabricated (Type II) fiber concrete (C-P-C) beam-column structure based on the bionic design idea of trunk structure. From the inside to the outside, the fiber concrete core 1, Primer layer 2, leveling layer 3, polyurea middle layer 4, impregnating resin 5 and carbon fiber outer layer 6. The section of the fiber concrete core 1 can be circular or square, and steel bars can be configured according to engineering needs. Apply the primer layer 2 evenly on the outside of the fiber concrete core 1 with a roller brush. The amount of application depends on the type of primer and the surface condition of the concrete. When the concentration of the primer is low, the general dosage standard is 0.25-0.3kg / ㎡ . After the primer layer 2 is dried, apply repair glue to the concrete surface as a leveling layer 3, and the general dosage of the repair glue is 0.5-1.5kg / m 2 . After ...

Embodiment 2

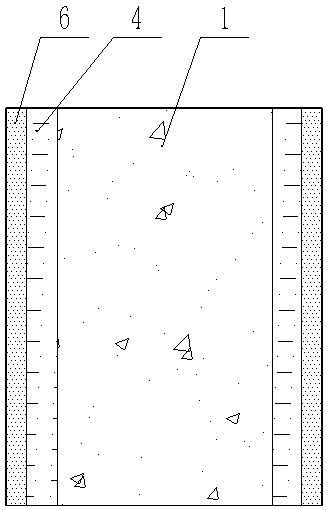

[0031] Such as image 3 and Figure 4 As shown, it is a "carbon fiber-polyurea" double-constrained prefabricated (type I) fiber concrete (C-P-C) beam-column structure based on the bionic design idea of trunk structure, including fiber concrete core 1, polyurea middle layer 4 and The carbon fiber outer layer 6 uses a CFRP composite pipe as the carbon fiber outer layer 6, and sprays polyurea elastomer with a uniform thickness on the inner wall of the CFRP pipe as the polyurea intermediate layer 4, and the spraying thickness can be adjusted between 0.5mm-10mm. After the polyurea gel is hardened, the fiber concrete is poured inside the pipe body and cured.

[0032] Compared with the traditional steel-concrete composite structure, the C-P-C composite member designed based on the characteristics of the trunk structure "woody matrix + cambium + active phloem" can derive diverse mechanical properties and durability. The advantages and positive effects of embodiments 1 and 2 are sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com