Nylon composite material, and raw materials, device and method for preparation of same

A technology for nylon composite materials and preparation devices, which is applied in the field of nylon composite materials and their preparation raw materials and preparation devices, and can solve the problems of low strength of nylon composite materials, poor compatibility of nylon and glass fibers, and generation of floating fibers. Achieve the effects of improving the interface bonding strength, facilitating industrial production, and benefiting the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

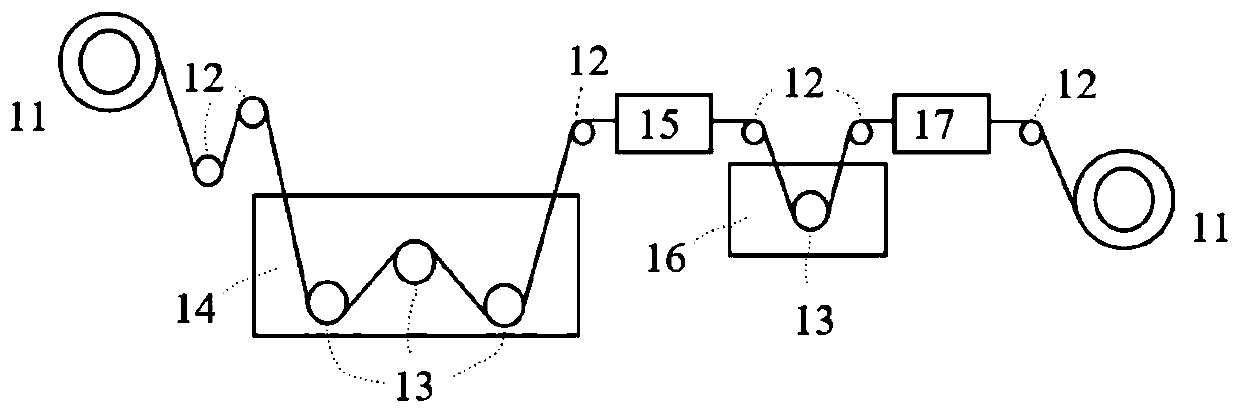

[0037] The preparation device of nylon composite material provided by the present invention comprises fiber pretreatment device 1 and cladding device 2; figure 1 As shown, the fiber pretreatment device 1 includes a bracket 11, a guide roller 12, a tension guide roller 13, an infiltration tank 14, a first dryer 15, a washing tank 16 and a second dryer 17, and the bracket 11 is used For fixing the continuous glass fiber, the guide roller 12 is used to guide the continuous glass fiber, and the soaking tank 14 and the washing tank 16 are provided with a tension guide roller 13 to guide and stretch the continuous glass fiber. The soaking tank 14 is used to soak the continuous glass fiber from the support 11, the first dryer 15 is used to dry the continuous glass fiber from the soaking tank 14, and the washing tank 16 is used to clean the source Wash the continuous glass fiber from the first dryer 15, and the second dryer 17 is used to dry the continuous glass fiber from the washing...

Embodiment 1

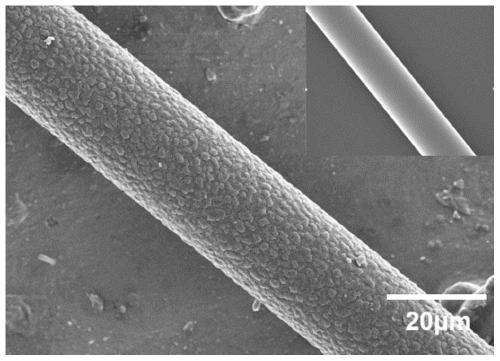

[0050] S1. Pretreatment of continuous glass fiber: such as figure 1 As shown, deionized water is used as a solvent to prepare a dopamine solution with a concentration of 2 g / L. The mass ratio of continuous glass fiber (10-15 μm in diameter) to dopamine solution is 25:1, and the continuous glass fiber roll passes through the guide roller 12 and the tension guide roller 13 are sent into the infiltration tank 14 equipped with dopamine solution for cyclic infiltration for 0.5h, then add the prepared Tris buffer solution to the dopamine solution, keep the pH value of the solution at 8.5, continue to circulate and stir infiltration for 5h, and then introduce The first dryer 15 is dried, and then sent to the washing tank 16 filled with ion water through the guide roller 12 and the tension guide roller 13 for washing, and then dried by the second dryer 17 to obtain pretreated continuous glass fiber roll. The SEM image of the pretreated continuous glass fiber roll is shown in image ...

Embodiment 2

[0053] S1. Pretreatment of continuous glass fiber: such as figure 1 As shown, deionized water is used as a solvent to prepare a dopamine solution with a concentration of 2 g / L. The mass ratio of continuous glass fiber (10-15 μm in diameter) to dopamine solution is 50:1, and the continuous glass fiber roll passes through the guide roller 12 and the tension guide roller 13 are sent into the infiltration tank 14 equipped with dopamine solution for cyclic infiltration for 5 hours, then add the configured Tris buffer solution to the dopamine solution, keep the pH value of the solution at 8.5, continue to circulate and stir and infiltrate for 5 hours, and then introduce the first A dryer 15 is dried, and then sent into a washing tank 16 filled with ionized water through a guide roller 12 and a tension guide roller 13 for washing, and then dried by a second dryer 17 to obtain a pretreated continuous glass fiber coil .

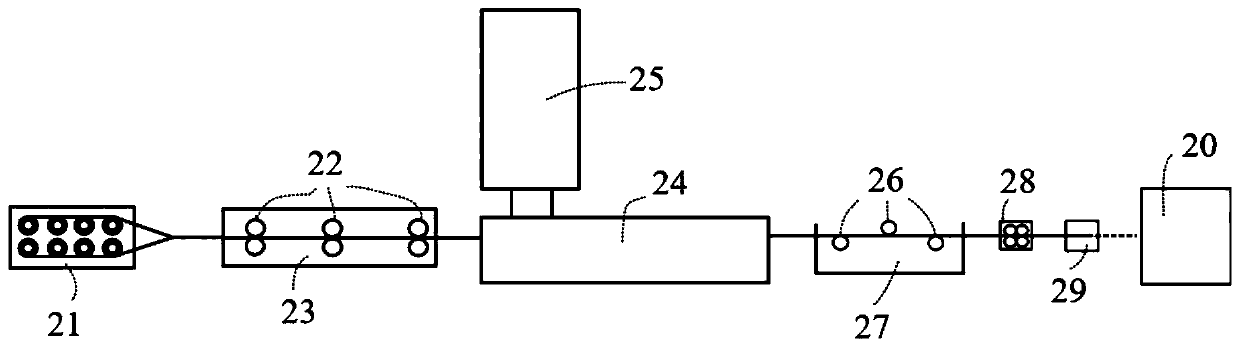

[0054] S2, coating treatment: such as figure 2As shown, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com