Flame retardant composition for electric cable outer sheaths, and preparation method thereof

A composition and cable technology, applied in the direction of rubber insulators, organic insulators, etc., can solve the problem of low flame retardant efficiency of inorganic flame retardants, affecting the processing performance, insulation performance and mechanical properties of EPDM rubber and its composite materials, and fracture Elongation deterioration and other problems, to achieve the effect of reducing entanglement, improving interfacial compatibility, and improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

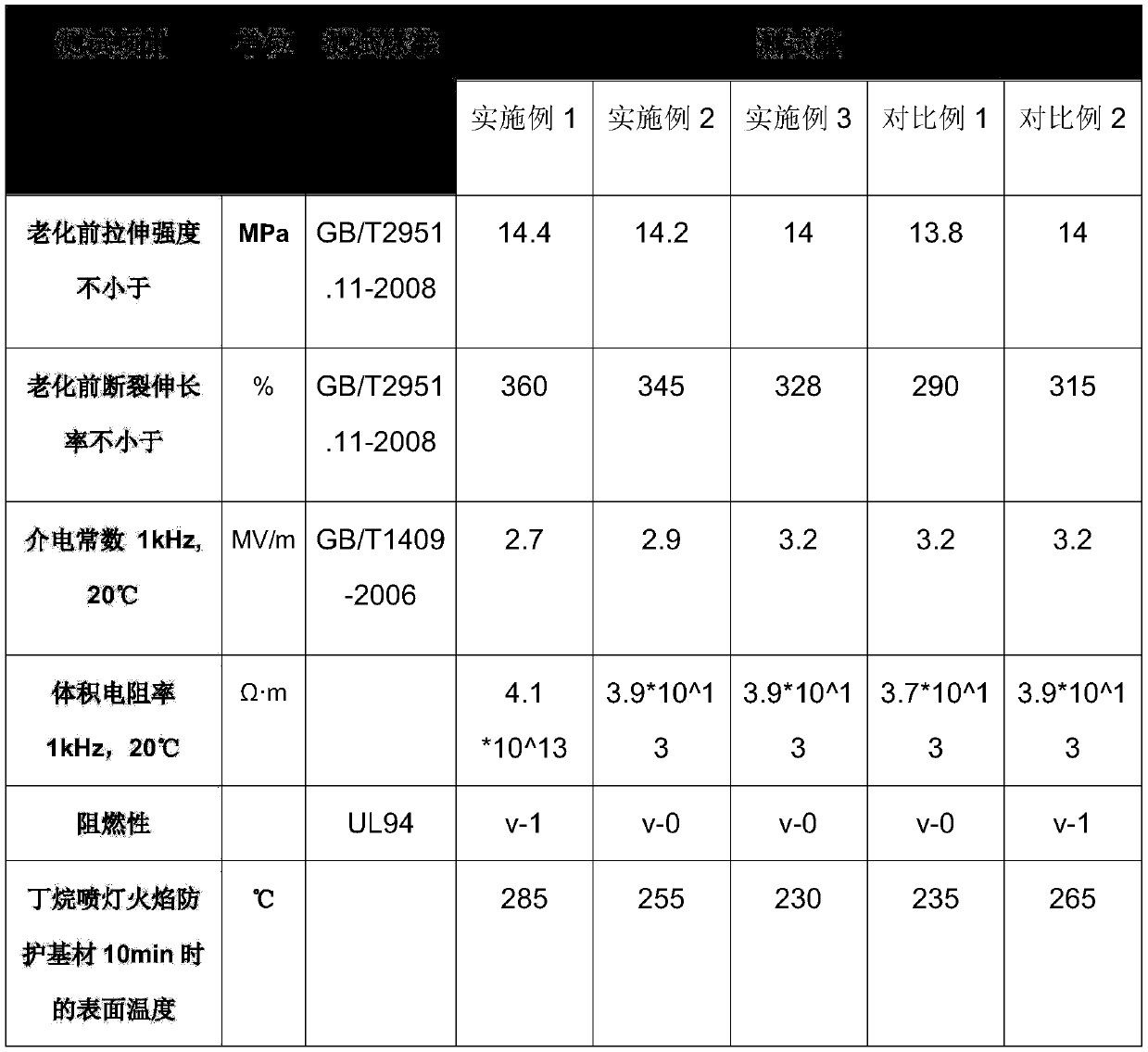

Examples

Embodiment 1

[0046] A flame retardant composition for an outer sheath of a cable, comprising the following components in parts by weight:

[0047] 60 parts of EPDM rubber;

[0048] 40 parts of low-density polyethylene;

[0049] 0.5 parts of polyethylene wax;

[0050] 4,4'-bis(α,α-dimethylbenzyl)diphenylamine: 4 parts;

[0051] p-Benzoquinone dioxime: 0.5 part;

[0052] Dicumyl peroxide: 2 parts;

[0053] Flame retardant filler: 50 parts

[0054] Aluminum diethylalkylphosphinate: 1 part.

[0055] Described flame-retardant filler is magnesium hydroxide / melamine urate compound, and its preparation method comprises the steps:

[0056] 1) Weigh 33.5 parts of magnesium hydroxide and place it in a vacuum drying oven, and dry it for 5 hours at 60 degrees Celsius for subsequent use;

[0057] 2) Weigh 3.5 parts of γ-aminopropyltriethoxysilane and 35 parts of toluene and mix and dilute;

[0058] 3) Place the γ-aminopropyltriethoxysilane toluene dilution obtained in the above step 2) and the m...

Embodiment 2

[0066] A flame retardant composition for an outer sheath of a cable, comprising the following components in parts by weight:

[0067] EPDM rubber: 65 parts;

[0068] Low-density polyethylene: 35 parts;

[0069] Polyethylene wax: 1.2 parts;

[0070] 4,4'-bis(α,α-dimethylbenzyl)diphenylamine: 7 parts;

[0071] p-Benzoquinone dioxime: 2 parts;

[0072] Dicumyl peroxide: 3.5 parts;

[0073] Flame retardant filler: 80 parts

[0074] Aluminum diethylalkylphosphinate: 3.5 parts.

[0075] Described flame-retardant filler is magnesium hydroxide / melamine urate compound, and its preparation method comprises the steps:

[0076] 1) Weigh 59 parts of magnesium hydroxide and place it in a vacuum drying oven, and dry it for 5 hours at 60 degrees Celsius for subsequent use;

[0077] 2) Weigh 7.5 parts of γ-aminopropyltriethoxysilane and 75 parts of toluene and mix and dilute;

[0078] 3) Place the γ-aminopropyltriethoxysilane toluene dilution obtained in the above step 2) and the magne...

Embodiment 3

[0086] A flame retardant composition for an outer sheath of a cable, comprising the following components in parts by weight:

[0087] EPDM rubber: 70 parts;

[0088] Low-density polyethylene: 30 parts;

[0089] Polyethylene wax: 2 parts;

[0090] 4,4'-bis(α,α-dimethylbenzyl)diphenylamine: 10 parts;

[0091] p-Benzoquinone dioxime: 3 parts;

[0092] Dicumyl peroxide: 5 parts;

[0093] Flame retardant filler: 100 parts

[0094] Aluminum diethylalkylphosphinate: 5 parts.

[0095] Described flame-retardant filler is magnesium hydroxide / melamine urate compound, and its preparation method comprises the steps:

[0096] 1) Weigh 77.5 parts of magnesium hydroxide and place it in a vacuum drying oven, and dry it for 5 hours at 60 degrees Celsius for subsequent use;

[0097] 2) Weigh 11.5 parts of γ-aminopropyltriethoxysilane and 115 parts of toluene and mix and dilute;

[0098] 3) Place the γ-aminopropyltriethoxysilane toluene dilution obtained in the above step 2) and the magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com