Preparation method of ceramic cover plate

A ceramic cover and ceramic technology, which is applied in the field of ceramic processing, can solve problems such as easy breakage, high hardness, and lower product yield, and achieve the effects of reducing slurry viscosity, improving production efficiency, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides a method for preparing a ceramic cover plate. The method for preparing a ceramic cover plate includes the following steps:

[0049] S1. Put the zirconia powder, organic solvent, and dispersant into the ball mill in proportion. After mixing for 1-12 hours, add binder and plasticizer, and continue mixing for 1-25 hours to prepare a slurry. This order can avoid The first combination of powder and binder can effectively reduce the viscosity of the slurry in the later stage.

[0050] Wherein, the mass percentage of zirconia powder is 45-60%.

[0051] The organic solvent is one or more of acetone, ethanol, butanol, toluene, xylene, bromochloromethane and diacetone, and the mass percentage of the organic solvent is 40-50%.

[0052] The binder is one or more of polyvinyl butyral, ethyl cellulose, polyvinyl alcohol, ether cellulose and polymethylpropylene, and the mass percentage of the binder is 3-15%.

[0053] The plasticizer is one or more of glycer...

Embodiment 2

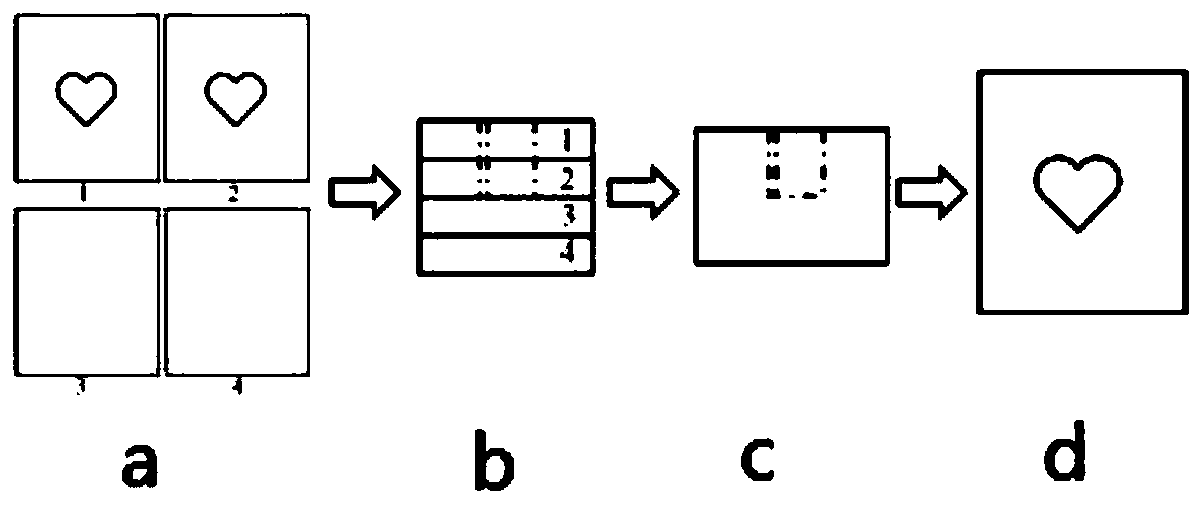

[0068] This embodiment provides a method for preparing a ceramic cover plate, using the ceramic blank obtained in Embodiment 1, such as figure 1 As shown in a-1d, the preparation method of the ceramic cover plate also includes the following steps:

[0069] S6, performing CNC machining, grinding, and polishing on the ceramic blank obtained in S5 to obtain a ceramic cover plate with a groove pattern.

[0070] Specifically, the casting sheet in S4 includes a first casting sheet 1, a second casting sheet 2, a third casting sheet 3 and a fourth casting sheet 4; With heart pattern.

[0071] Specifically, the specific steps of grinding and polishing are as follows: adsorb the sample on the fixture, and perform surface grinding. The grinding parameters are: the diamond grinding head of the cutter d6-400#, each cutting 0.03mm, and grinding and leveling; then polishing, After polishing for 2 to 3 hours, the mirror effect will be achieved.

[0072] In this embodiment, 20 samples were ...

Embodiment 3

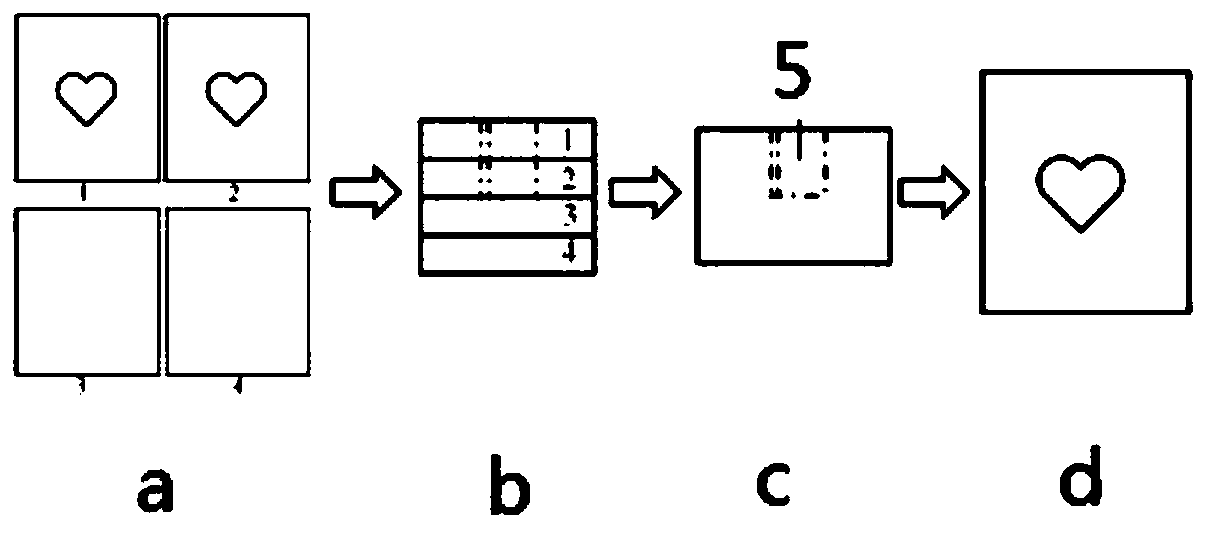

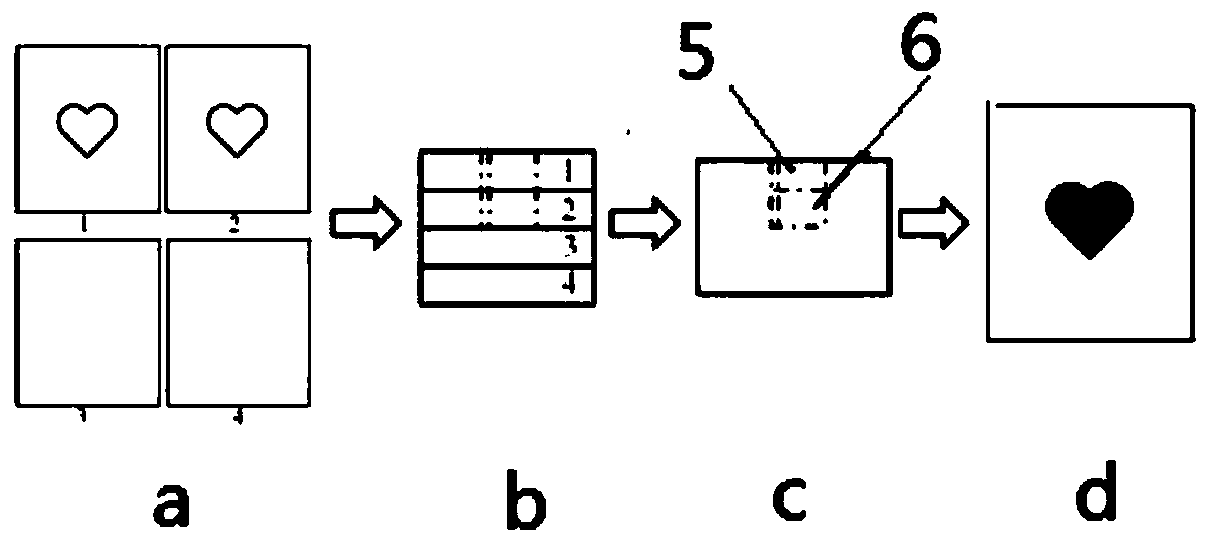

[0074] This embodiment provides a method for preparing a ceramic cover plate, using the ceramic blank obtained in Embodiment 1, such as figure 2 As shown in a-2d, the preparation method of the ceramic cover further includes the following steps:

[0075] S6. Filling the patterned grooves with a transparent covering layer 5, and performing CNC machining, grinding, and polishing on the obtained ceramic blank to obtain a ceramic cover plate with grooved patterns. For example, the pattern is a heart.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com