Synthesis method of hydrogen-enriched water ceramic filter element

A technology of ceramic filter elements and synthesis methods, applied in chemical instruments and methods, filtration treatment, water/sewage treatment, etc., can solve problems affecting the use effect of ceramic filter elements, agglomeration, high cost, etc., and achieve good application universality , Uniform micropores, guaranteed effect of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for synthesizing a hydrogen-rich water ceramic filter element is prepared according to the following scheme:

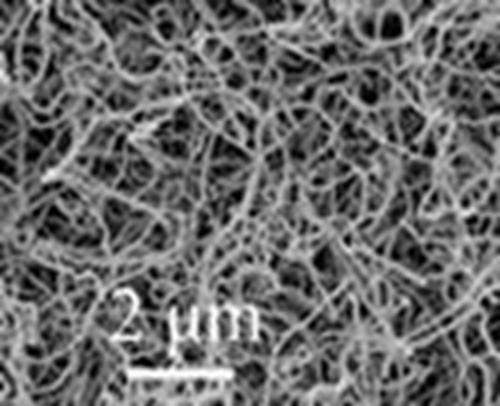

[0031] Step 1. According to the number of parts by mass, 41 parts of germanite powder, 16 parts of tourmaline powder, 12 parts of carboxylated double-walled carbon nanotubes and 27 parts of dolomite powder are mixed and ground for 6 hours to form the substrate powder of the material; Add 1 part of selenium glycine, 0.07 parts of hydroxyapatite nanowires, 6 parts of stearic acid, and mix at 90°C for 4 hours; obtain activated substrate powder;

[0032] Step 2. Mix and grind 12 parts of magnesium metal powder and 8 parts of KDF alloy powder according to the parts by mass for 7 hours to form the hydrogen-rich powder of the material;

[0033] Step 3: According to the mass parts, add 75 parts of activated substrate powder and 2 parts of titanium dioxide nanowires into the mixer, mix for 5 hours, then add 65 parts of purified water and 7 parts of coconut oil ...

Embodiment 2

[0042] A method for synthesizing a hydrogen-rich water ceramic filter element is prepared according to the following scheme:

[0043] Step 1. Mix and grind 20 parts of germanite powder, 10 parts of tourmaline powder, 10 parts of carboxylated double-walled carbon nanotubes and 25 parts of dolomite powder according to the number of parts by mass to form the substrate powder of the material; Add 0.3 parts of selenium glycine, 0.03 parts of hydroxyapatite nanowires, and 4 parts of stearic acid, and mix at 80° C. for 2 hours; obtain activated substrate powder;

[0044] Step 2. Mix and grind 10 parts of magnesium metal powder and 5 parts of KDF alloy powder for 5 hours according to the parts by mass to form the hydrogen-rich powder of the material;

[0045] Step 3: Add 70 parts of activated base material powder and 1 part of titanium dioxide nanowires into the mixer according to the mass parts, mix for 3 hours, then add 60 parts of purified water and 5 parts of coconut oil fatty aci...

Embodiment 3

[0051] A method for synthesizing a hydrogen-rich water ceramic filter element is prepared according to the following scheme:

[0052] Step 1. According to the number of parts by mass, 50 parts of germanite powder, 30 parts of tourmaline powder, 20 parts of carboxylated double-walled carbon nanotubes and 35 parts of dolomite powder are mixed and ground for 10 hours to form the substrate powder of the material; Add 3 parts of selenium glycine, 0.8 parts of hydroxyapatite nanowires, and 10 parts of stearic acid, and mix for 5 hours at 120° C. to obtain activated substrate powder;

[0053] Step 2. Mix and grind 15 parts of magnesium metal powder and 10 parts of KDF alloy powder according to the parts by mass for 10 hours to form the hydrogen-rich powder of the material;

[0054] Step 3. According to the mass parts, 80 parts of activated substrate powder and 5 parts of titanium dioxide nanowires are added to the mixer, mixed for 8 hours, and then 70 parts of purified water and 10 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com