Synthesis method of graded porous carbon nanometer material

A technology of carbon nanomaterials and synthesis methods, which is applied in the field of synthesis of hierarchical porous carbon nanomaterials, can solve the problems of complex preparation process, large organic solvent, unfavorable wide application and exploration of hierarchical porous carbon materials, etc. High adaptability and mild condition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a synthetic method of hierarchical porous carbon nanomaterials, comprising the following steps:

[0036] A) mixing and reacting small organic molecules containing multichelating groups or adjacent hydroxyl groups and inorganic zinc salts in an alkaline aqueous solution to obtain a precursor precipitated in the form of precipitation;

[0037] B) performing high temperature pyrolysis on the precursor to obtain hierarchical porous carbon nanomaterials.

[0038] In the invention, firstly, small organic molecules containing multi-chelating groups or adjacent hydroxyl groups and inorganic zinc salts are mixed and reacted in an alkaline aqueous solution to obtain a precursor precipitated in the form of precipitation.

[0039] Specifically, a small organic molecule containing a multichelating group or an ortho-diphenol is dissolved in an alkaline aqueous solution to obtain a mixed solution;

[0040] The small organic molecules containing multichelating g...

Embodiment 1

[0062] a. Disperse 0.8g of terephthalic acid into 80ml of water, then add 2.67ml of triethylamine, after stirring for half an hour, then add 5.73g of zinc nitrate hexahydrate, and continue stirring for 24 hours to obtain the precipitated precursor ;

[0063] b. Centrifuge the above-mentioned aqueous solution containing the precursor to remove water, then add clean water and repeat washing three times by centrifugation, and finally put it into an oven for drying;

[0064] c. Transfer the completely dried precursor to a quartz crucible, put it into a tube furnace, and then pass in nitrogen as a protective gas, raise the temperature of the tube furnace to 1000 °C at a rate of 5 °C / min, and keep it for 2 hours; Cool down to 500°C at a rate of 5°C / min, and finally cool down to room temperature naturally; maintain normal pressure in the tube furnace. Obtain hierarchical porous carbon nanomaterials;

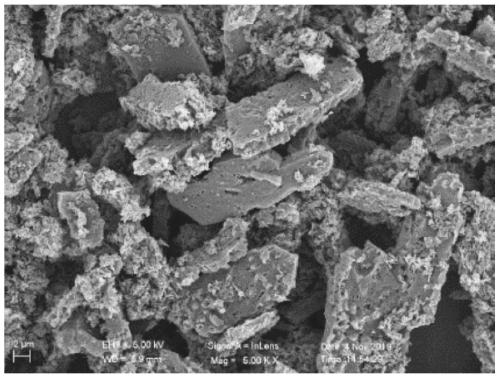

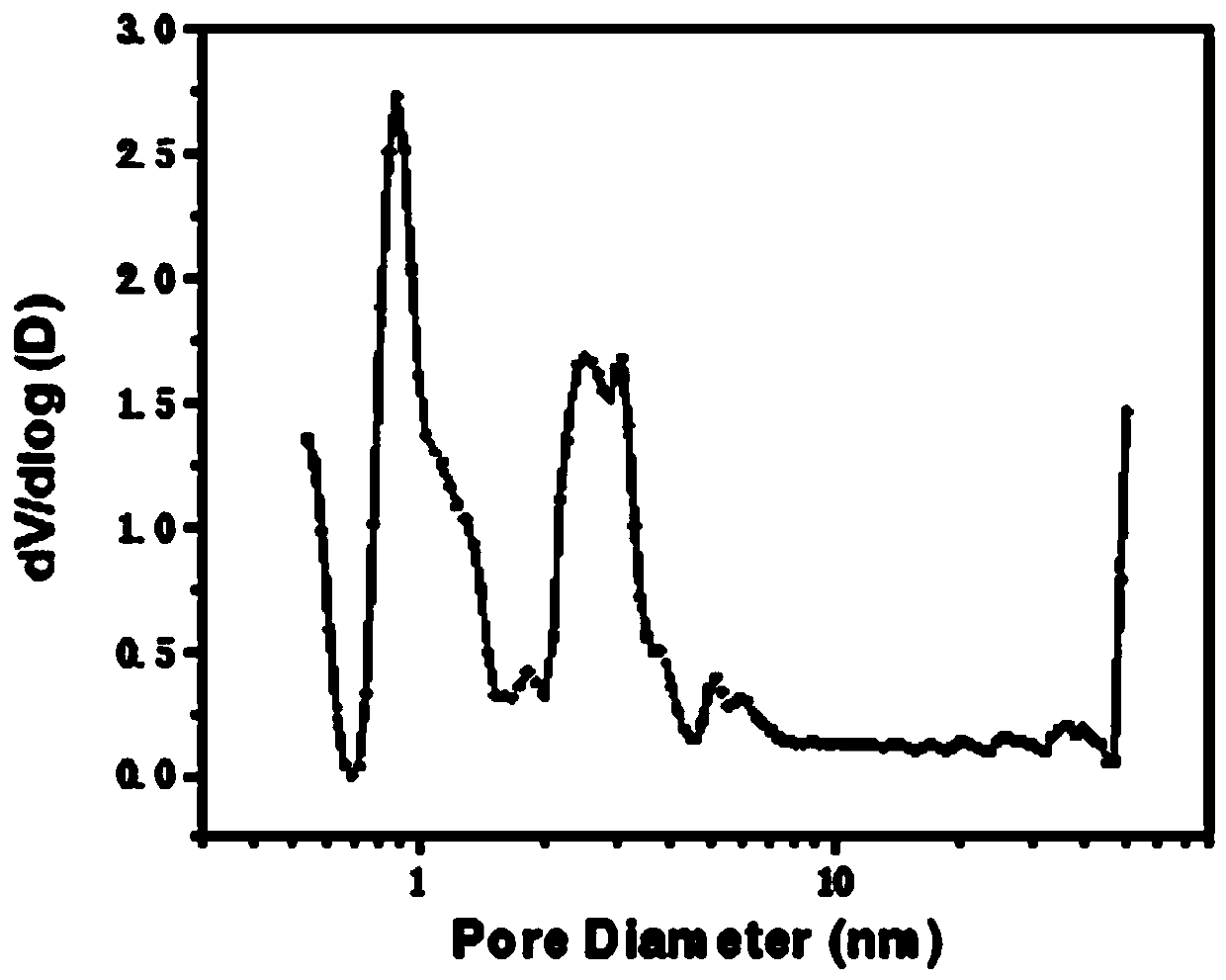

[0065] figure 1 It is a scanning electron micrograph of the hierarchical porous ...

Embodiment 2

[0069] a. Disperse 0.8g of terephthalic acid and 0.209mg of suberic acid into 80ml of water, then add 3.34ml of triethylamine, after stirring for half an hour, add 7.16g of zinc nitrate hexahydrate, and continue stirring for 24 hours to obtain the following: Precursors precipitated in the form of precipitation;

[0070] b. Centrifuge the above-mentioned aqueous solution containing the precursor to remove water, then add clean water and repeat washing three times by centrifugation, and finally put it into an oven for drying;

[0071] c. Transfer the completely dried precursor to a quartz crucible, put it into a tube furnace, and then pass in nitrogen as a protective gas, raise the temperature of the tube furnace to 1000 °C at a rate of 5 °C / min, and keep it for 2 hours; Cool down to 500°C at a rate of 5°C / min, and finally cool down to room temperature naturally; maintain normal pressure in the tube furnace. Obtain hierarchical porous carbon nanomaterials;

[0072] image 3 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com