Preparation method for NxC-coated metal nanoparticle core-shell-structured material

A metal nanoparticle, core-shell structure technology, applied in metal material coating process, metal processing equipment, catalyst activation/preparation, etc., can solve the problems of poor product selectivity, unsatisfactory, low catalyst activity, etc., and achieve good selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

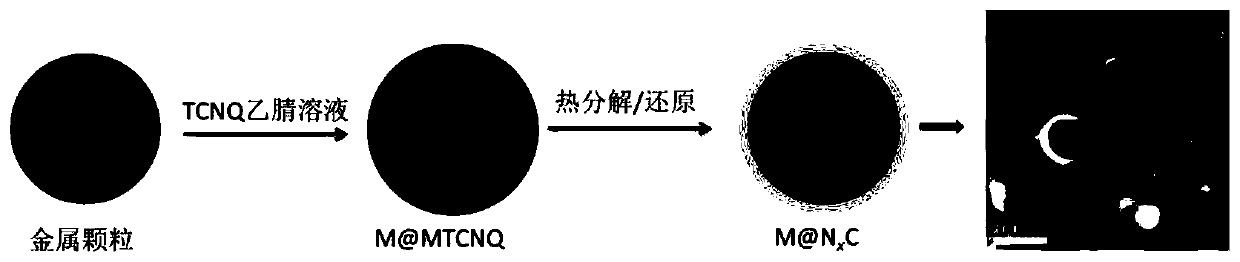

[0031] Weigh 100mg of commercial nano-Cu powder into a 150mL round bottom flask, add 100mL 0.1M H 2 SO 4 Aqueous solution, stirred for 10 minutes to remove surface oxides. Wash with deionized water several times and centrifuge. After freeze-drying, weigh 50 mg and add it to 100 mL of acetonitrile solvent, ultrasonically disperse for 10 minutes, add 10 mg of 7,7,8,8-tetracyanoquinodimethane (TCNQ) under stirring conditions, continue stirring for 30 minutes, filter After washing with acetonitrile and freeze-drying for 12 hours, CuTCNQ-coated Cu nanoparticle precursors were obtained.

[0032] The above precursor was heated to 350 °C at a heating rate of 5 °C / min in a tube furnace under the condition of argon and hydrogen mixed gas, kept for 2 hours and then naturally cooled to room temperature. get N x C-wrapped Cu nanoparticles core-shell structure material (Cu@N x C).

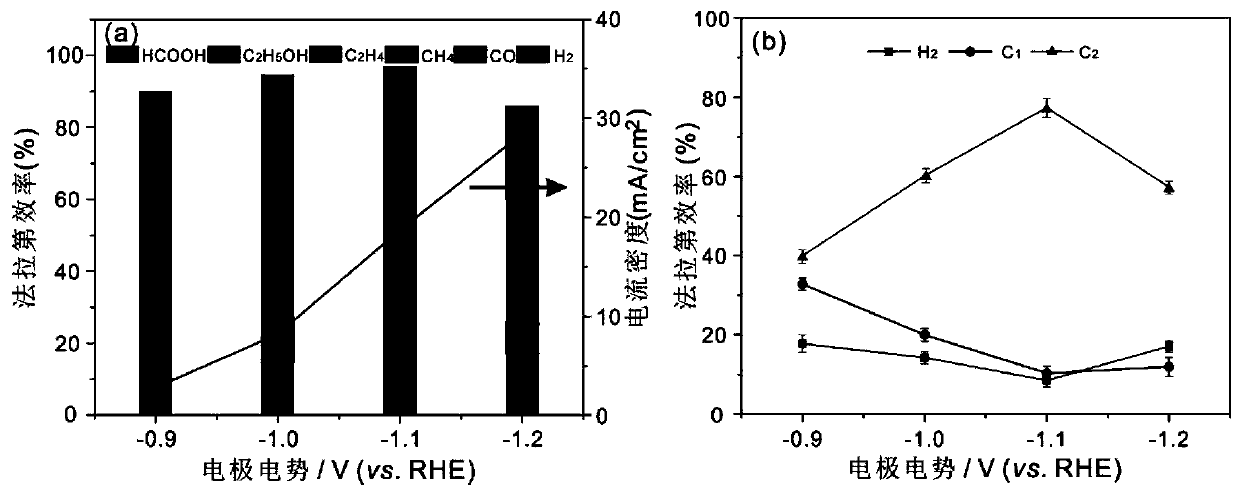

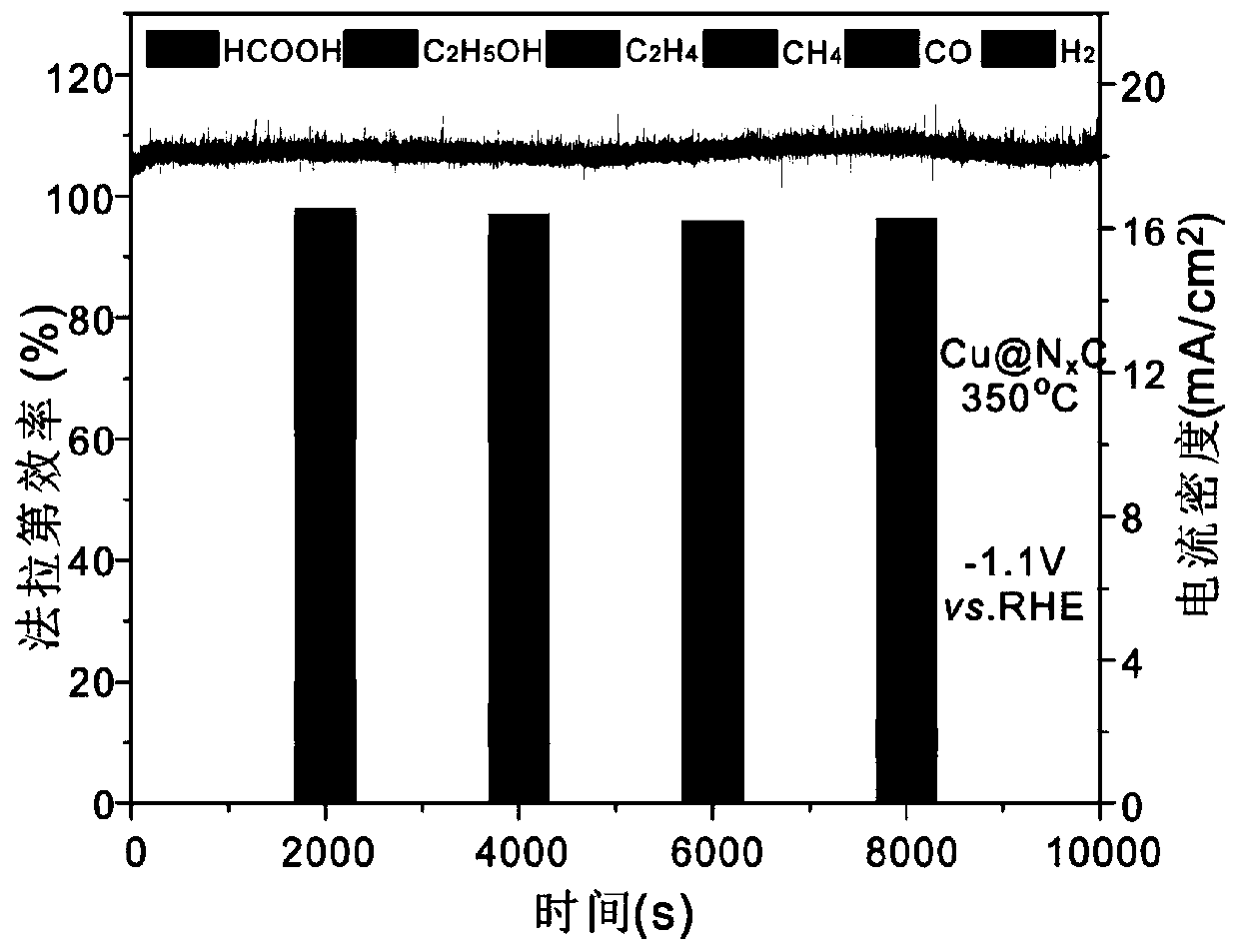

[0033] N obtained from this example x C-wrapped Cu nanoparticle core-shell structure material for elec...

Embodiment 2

[0035] Weigh 100mg of commercial nano-Cu powder into a 150mL round bottom flask, add 100mL 0.1M H 2 SO 4 Aqueous solution, stirred for 10 minutes to remove surface oxides. Wash with deionized water several times and centrifuge. After freeze-drying, weigh 50 mg and add it to 100 mL of acetonitrile solvent, ultrasonically disperse for 10 minutes, add 2.5 mg of 7,7,8,8-tetracyanoquinodimethane (TCNQ) under stirring conditions, and continue stirring for 30 minutes, Filtration, washing with acetonitrile, and freeze-drying for 12 h gave CuTCNQ-coated Cu nanoparticle precursors.

[0036] The above precursor was heated to 350 °C at a heating rate of 5 °C / min in a tube furnace under the condition of argon and hydrogen mixed gas, kept for 2 hours and then naturally cooled to room temperature. get N x C-wrapped Cu nanoparticles core-shell structure material (Cu@N x C).

Embodiment 3

[0038] Weigh 100mg of commercial nano-Cu powder into a 150mL round bottom flask, add 100mL 0.1M H 2 SO 4 Aqueous solution, stirred for 10 minutes to remove surface oxides. Wash with deionized water several times and centrifuge. After freeze-drying, weigh 50 mg and add it to 100 mL of acetonitrile solvent, ultrasonically disperse for 10 minutes, add 5 mg of 7,7,8,8-tetracyanoquinodimethane (TCNQ) under stirring conditions, continue stirring for 30 minutes, filter After washing with acetonitrile and freeze-drying for 12 hours, CuTCNQ-coated Cu nanoparticle precursors were obtained.

[0039] The above precursor was heated to 350 °C at a heating rate of 5 °C / min in a tube furnace under the condition of argon and hydrogen mixed gas, kept for 2 hours and then naturally cooled to room temperature. get N x C-wrapped Cu nanoparticles core-shell structure material (Cu@N x C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com