Catalyst and preparation method for preparing 1,6-hexanediol by reduction of adipic acid

A technology of catalyst and adipic acid, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of high preparation cost, achieve the effects of reducing production cost, improving performance, and good industrialization prospects

Active Publication Date: 2022-06-03

QINGDAO UNIV OF SCI & TECH

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to seek a catalyst for the reduction of adipic acid to prepare 1,6-hexanediol and a preparation method thereof, which solves the problem that the existing catalyst for the reduction of adipic acid to prepare 1,6-hexanediol has a relatively high preparation cost The problem

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2-6

Embodiment 7

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

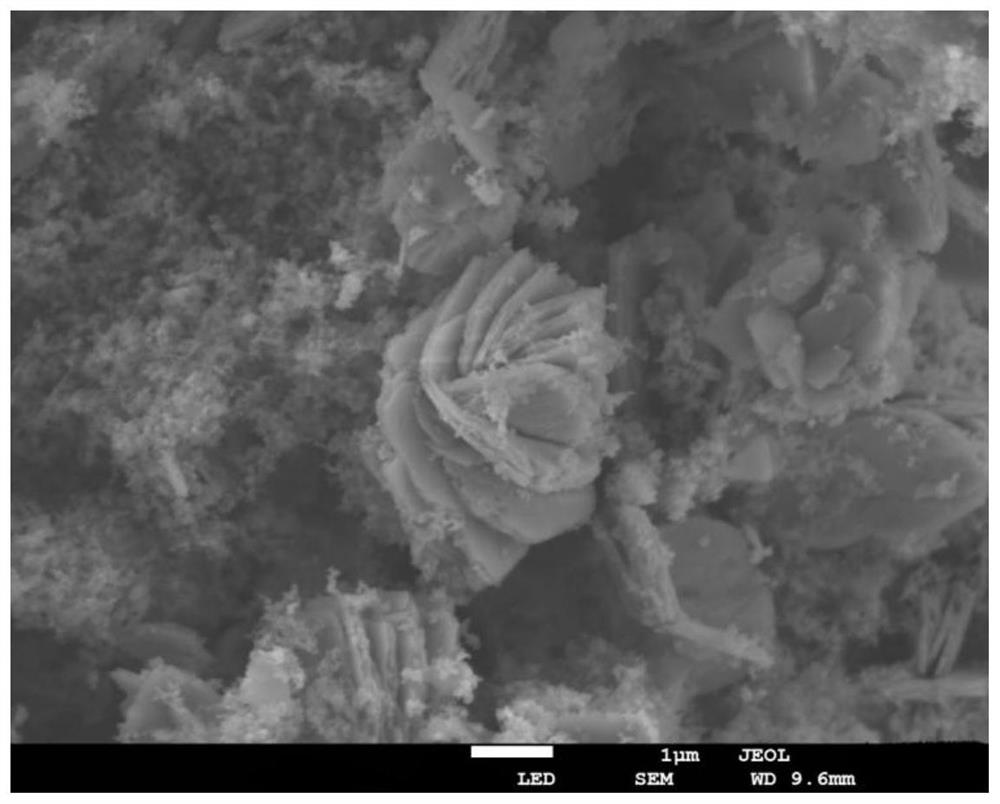

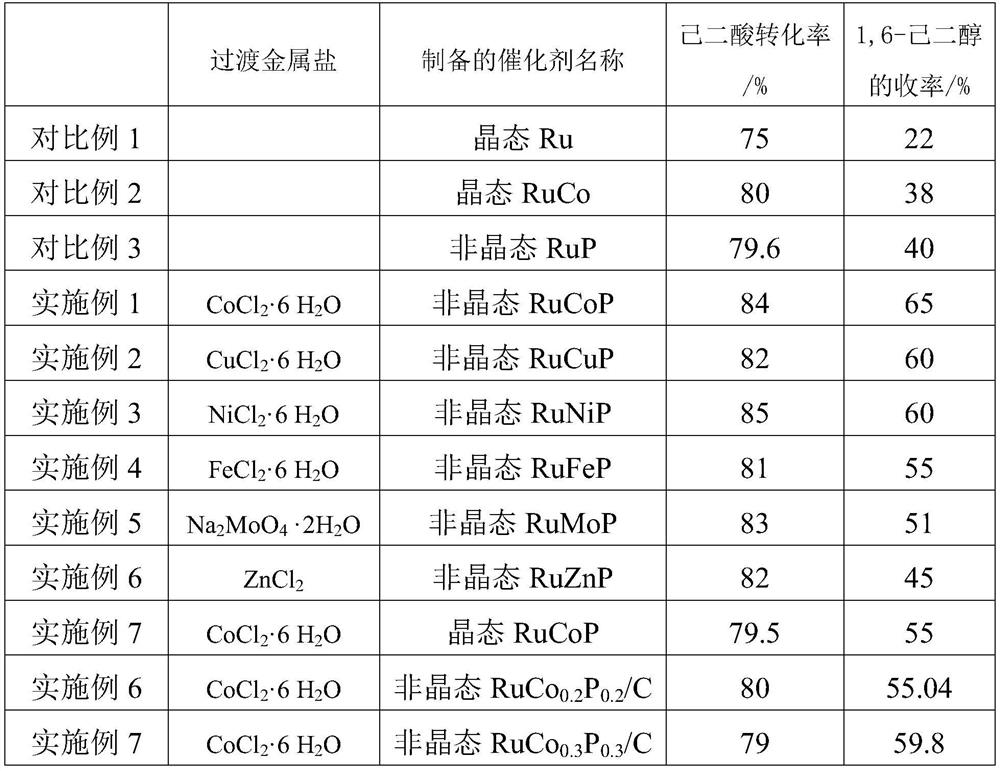

The invention discloses a catalyst for preparing 1,6-hexanediol by reduction of adipic acid, which comprises an active component, a transition metal, phosphorus and a carrier, the active component is Ru, and the transition metal is Co, Cu , at least one of Ni, Fe, Mo and Zn, and the carrier is a porous structure material, such as diatomaceous earth, activated carbon, etc. First configure a mixed solution containing soluble salts and phosphorus salts of any of the above transition metals, and pass inert gas into the solution to form a gas-liquid interface with inert gas bubbles as a template; then slowly add a certain concentration of NaBH 4 solution, and then quickly add catalyst active components; add the reacted mixed solution to the carrier, react for a period of time, wash with water until neutral, filter, and dry to obtain an amorphous catalyst. The catalyst has low cost, the conversion rate of adipic acid is as high as 90%, and the yield of 1,6-hexanediol can reach 65%, which has achieved good technical effects and has good industrialization prospects.

Description

Catalyst and preparation method for preparing 1,6-hexanediol by reducing adipic acid Technical field: The present invention relates to catalyst preparation technical field, be specifically related to a kind of inert bubble template method that can A catalyst for the synthesis of 1,6-hexanediol by one-step diacid method. Background technique: Diols have an important position in industry, and they are used as raw materials in various fine chemicals, the materials of medicines. materials and biodegradable polymers. 1,6-Hexanediol (HDO) is one of the indispensable chemical raw materials. HDO can be combined with organic acids, Isocyanates, anhydrides can react to form different types of derivatives, and can also be used to synthesize caprolactone / caprolactam and polymers, Such as polyester, polyurethane and various adhesives to improve the mechanical strength, hydrolysis resistance, heat resistance, chemical resistance, etc. performance. Polyurethane, polyester, coat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B01J27/185B01J27/19B01J37/16C07C29/147C07C31/20

CPCC07C29/147B01J27/1856B01J27/19B01J37/16C07C31/20Y02P20/584

Inventor 王许云巩伟王辉王荣方

Owner QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com