Implanting jawbone with dental implanting sites and digital processing method thereof

A technology for dental implants and dental implants, applied in metal processing equipment, dental implants, dentistry, etc., can solve problems such as delayed recovery time, high operation requirements, and fragile implanted jaws, so as to enhance the structural diversity of the jaws, shorten the Effect of treatment cycle and reduction of surgical risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below.

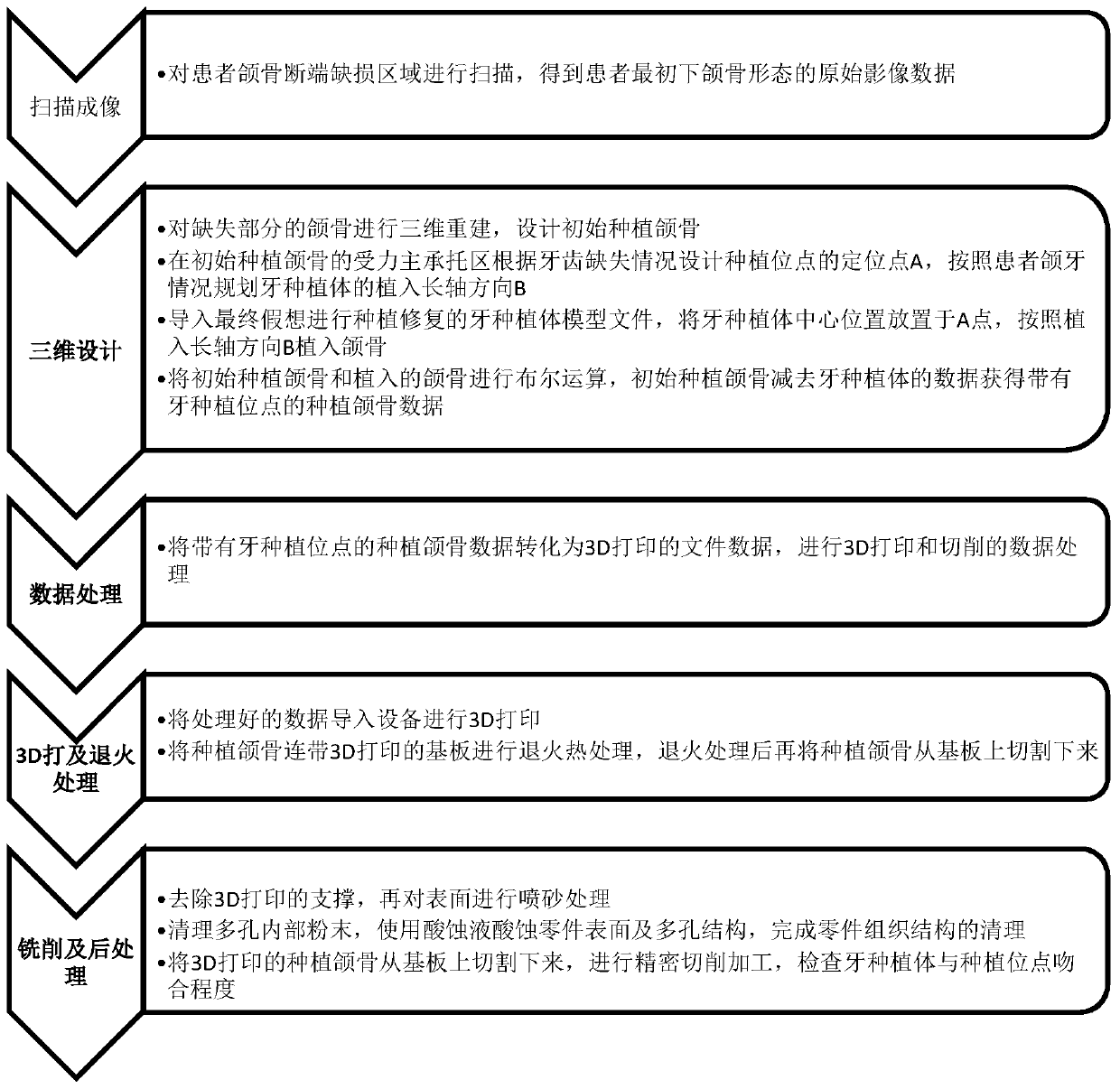

[0032] The digitized processing mode of the implanted jaw with the dental implant site disclosed by the present invention comprises the following steps:

[0033] Scanning imaging: scan the defect area of the broken end of the patient's jaw to obtain the original image data of the patient's initial jaw shape;

[0034] CBCT scanning is preferred for scanning and imaging. CBCT is an exclusive scanning method for dental and maxillofacial parts. It uses three-dimensional cone beam X-rays for scanning. For high-resolution areas, such as tooth root canal system, mandible, mandibular nerve canal, temporomandibular The imaging quality of the fine hard tissue structure of the joint is good. During scanning, the scanning plane is parallel to the patient's orbito-auricular plane, and the scanning range is from the patient's superior orbital edge to the lower edge of the mandible.

[0035] Three-dimensional design: perform thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com