Method for preparing composite separator for lithium sulfur battery

A composite diaphragm, lithium-sulfur battery technology, applied in lithium batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problem that the flame retardant performance cannot be well improved, and achieve the suppression of the shuttle effect and the improvement of heat resistance. performance, the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of composite diaphragm provided by the invention may further comprise the steps:

[0031] (1) React an equimolar amount of diamine with dianhydride to obtain a polyamic acid solution; take a part of the polyamic acid solution as a spinning solution for spinning to form a film, and obtain a polyimide spinning solution after thermal imidization treatment. Silk-based membranes; specifically include:

[0032] (1.1) Add the diamine into the solvent, stir in a cold trap at -3°C under the protection of nitrogen until dissolved; then add the dianhydride into the diamine solution in four times; after reacting for 12 hours, a polyamic acid solution is obtained; The solvent is N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAc) or N-methylpyrrolidone (NMP);

[0033] The diamine is any one or more of the following: p-phenylenediamine, 4,4'-diaminodiphenyl ether, biphenylenediamine, 2,2-bis(3-amino-4-hydroxyphenyl ) hexafluoropropane, 4,4'-diaminodiphe...

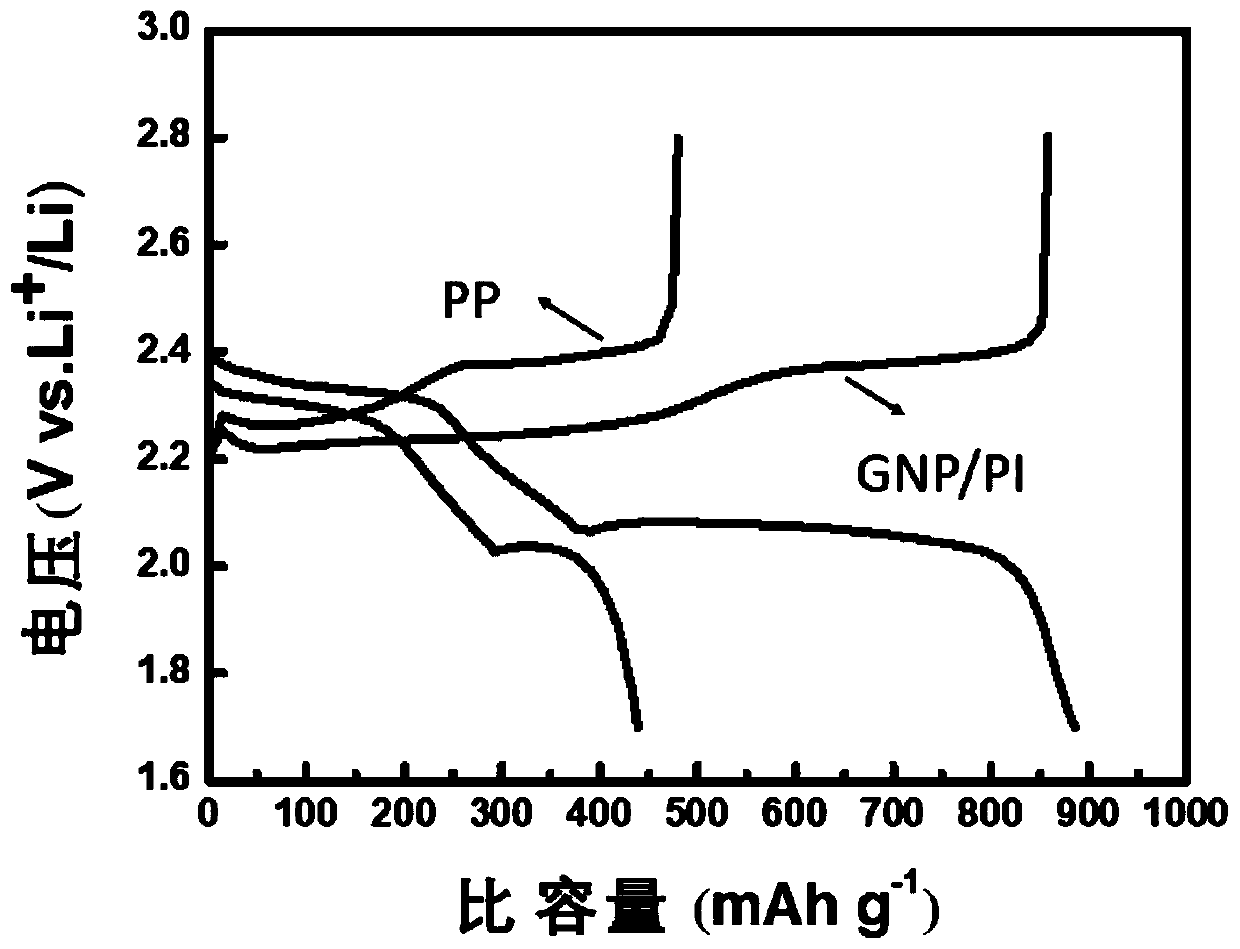

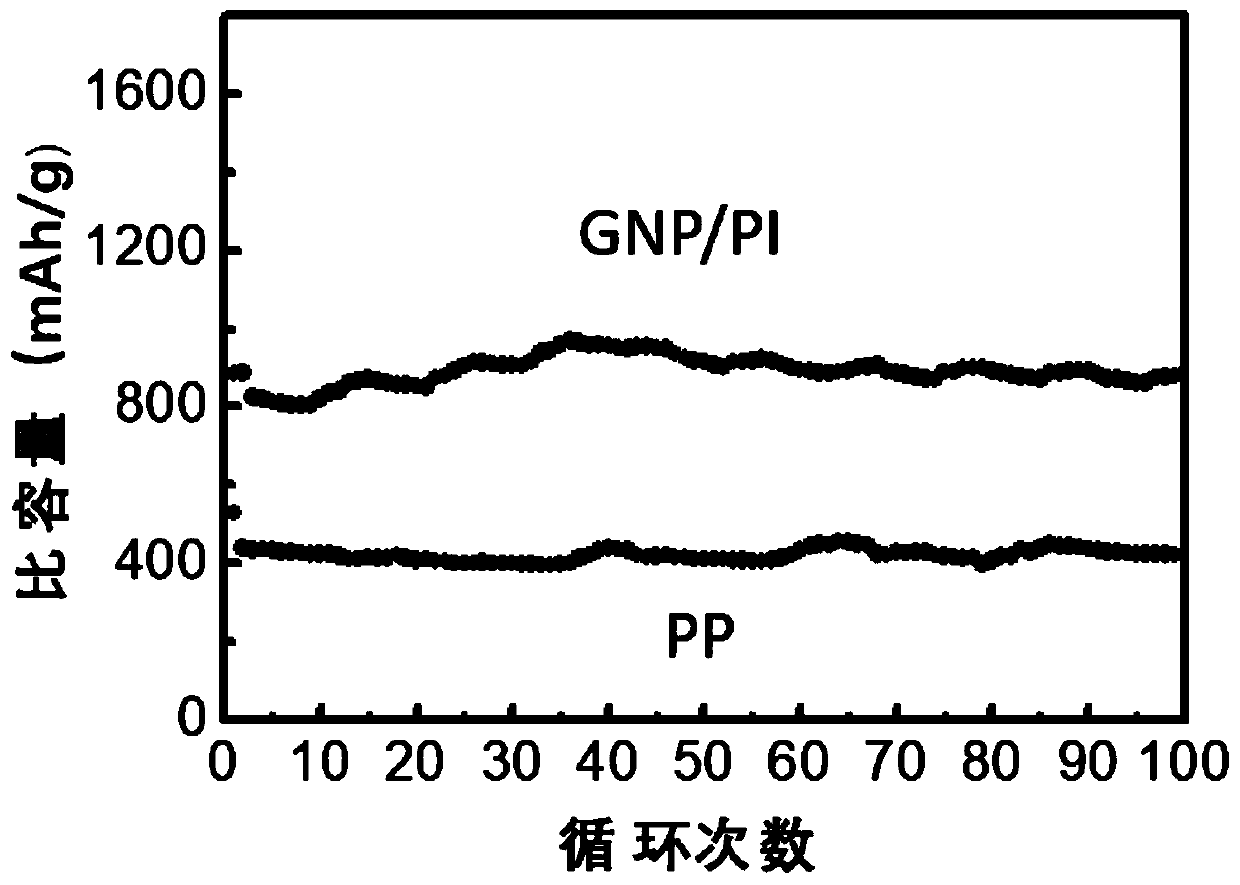

Embodiment 1

[0042] An example of the preparation of a separator sandwiched by a nitrogen-doped carbide film.

[0043]Preparation of diaphragm: Weigh 2.0024g of 4,4'-diaminodiphenyl ether, dissolve 4,4'-diaminodiphenyl ether in 40mL of DMF in a cold trap at -3°C under a nitrogen atmosphere, and Equimolar amounts of pyromellitic dianhydride were added into the solution four times every half hour. Specifically, 0.7271 g was added for the first and second times, 0.3635 g was added for the third and fourth times, and reacted for 12 hours to obtain poly Amic acid solution. Then the polyamic acid solution was subjected to electrospinning, the electrospinning temperature was 32°C, the spinning voltage was 17KV, the distance between the spinning needle and the receiver was 20cm, and the spinning time was 2h, and the polyamic acid obtained by spinning was The non-woven separator was dried overnight in an oven at 60 °C, and then the polyamic acid non-woven film was placed in N 2 Under protection, ...

Embodiment 2

[0050] Preparation of diaphragm: Weigh 2.0024g of 4,4'-diaminodiphenyl ether, dissolve 4,4'-diaminodiphenyl ether in DMF in a cold trap at -3°C under a nitrogen atmosphere, and equimolarly A certain amount of 3,3',4,4'-biphenyltetracarboxylic dianhydride was added into the solution four times every half hour, specifically, 0.9807g was added for the first and second times, and 0.9807g was added for the third and fourth times respectively. Add 0.4904g and react for 12 hours to obtain a polyamic acid solution, then electrospin the polyamic acid solution, the electrospinning temperature is 32°C, the spinning voltage is 17KV, and the distance between the spinning needle and the receiver is 20cm , spinning for 2h, the polyamic acid non-woven membrane obtained by spinning was dried overnight in an oven at 60°C, and then dried under N 2 Under protection, the temperature is raised in steps of 5°C / min, and the temperature is kept at 100°C, 200°C, and 300°C for 1 hour respectively, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com