Composite cooling positive electrode-based GaN planar gunn diode and fabrication method thereof

A Gunn diode and anode technology is applied in the field of GaN planar Gunn diodes and their preparation based on composite heat dissipation anodes. The effect of reducing the self-heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

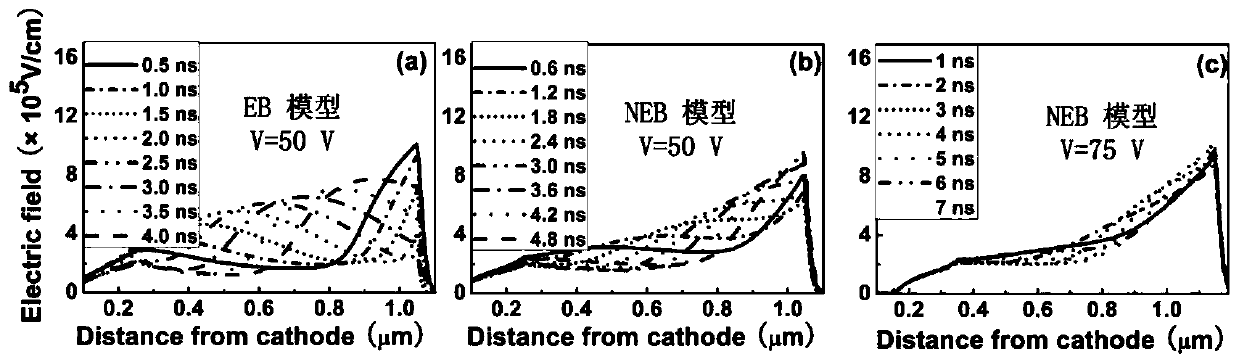

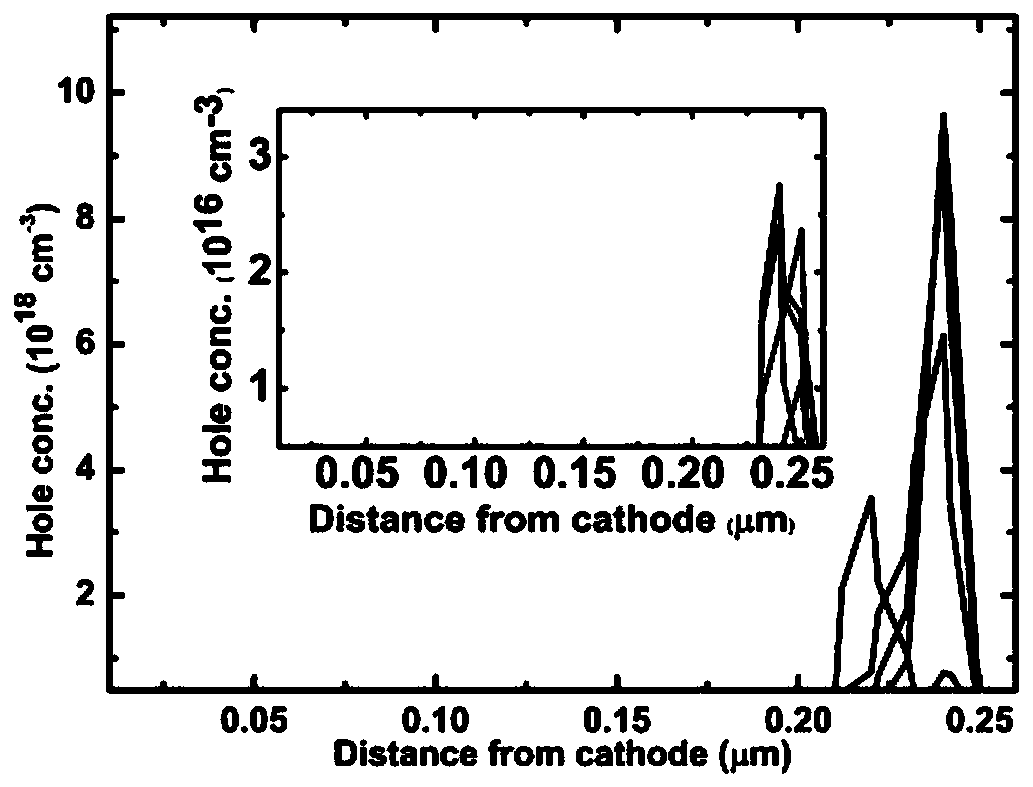

Problems solved by technology

Method used

Image

Examples

Embodiment 1

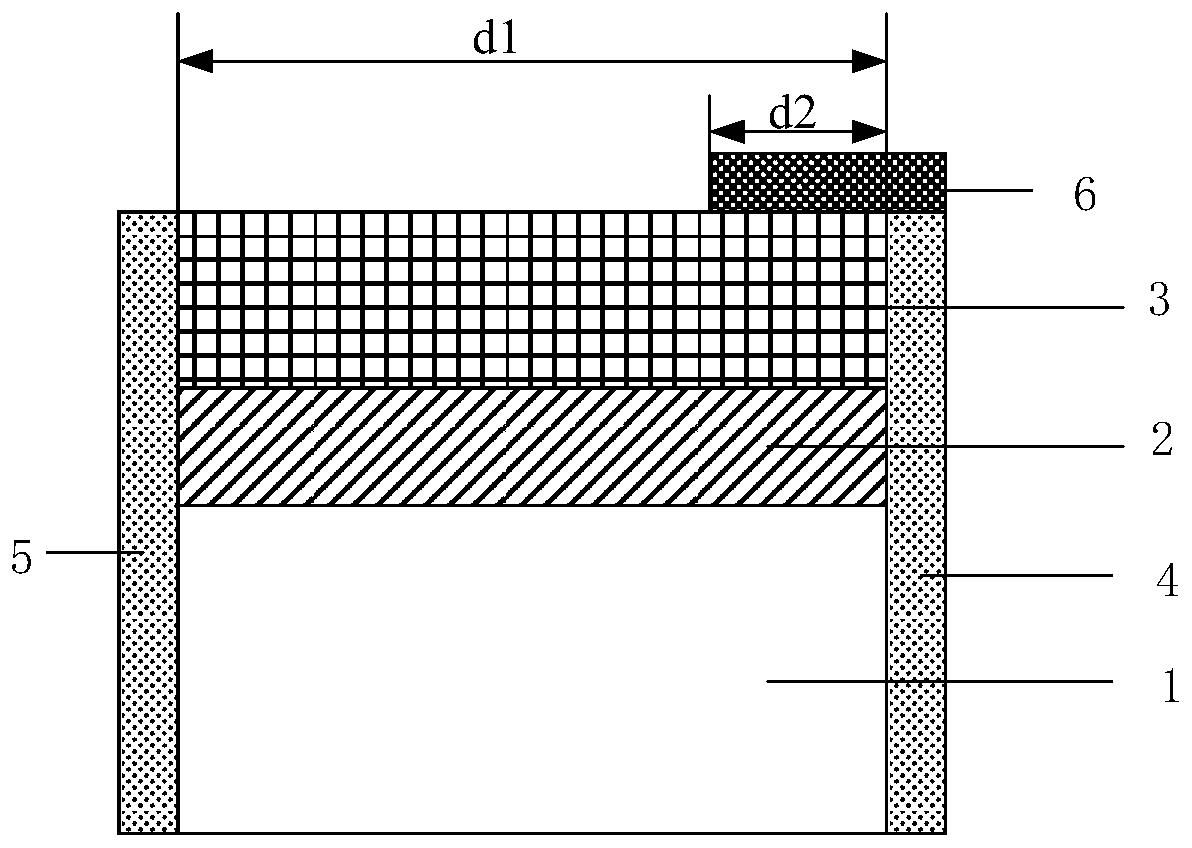

[0042] See figure 2 , figure 2 The schematic diagram of the structure of the first GaN planar Gunn diode based on the compound heat dissipation anode provided by the embodiment of the present invention. The planar Gunn diode includes an AlGaN back barrier layer 1 , a GaN channel layer 2 , an AlGaN barrier layer 3 , an ohmic contact anode 4 , an ohmic contact cathode 5 and a Schottky extension layer 6 .

[0043] Among them, the GaN channel layer 2 is located on the AlGaN back barrier layer 1; the AlGaN barrier layer 3 is located on the GaN channel layer 2; the ohmic contact anode 4 is located on the AlGaN back barrier layer 1, the GaN channel layer 2 and the AlGaN barrier layer One end of the layer 3, the ohmic contact cathode 5 is located at the other end of the AlGaN back barrier layer 1, the GaN channel layer 2 and the AlGaN barrier layer 3; the Schottky extension layer 6 is located on the AlGaN barrier layer 3 and covers the ohmic contact on anode 4.

[0044]In order t...

Embodiment 2

[0055] On the basis of Example 1, please refer to Figure 5 , Figure 5 A schematic diagram of the structure of the second GaN planar Gunn diode based on the compound heat dissipation anode provided by the embodiment of the present invention. The planar Gunn diode includes: an AlGaN back barrier layer 1 , a GaN channel layer 2 , an AlGaN barrier layer 3 , an ohmic contact anode 4 , an ohmic contact cathode 5 , a heat dissipation film 7 and a Schottky extension layer 6 .

[0056] Wherein, the GaN channel layer 2 is located on the AlGaN back barrier layer 1 , and the AlGaN barrier layer 3 is located on the GaN channel layer 2 . The ohmic contact anode 4 is located at one end of the GaN channel layer 2 and the AlGaN barrier layer 3 , and the ohmic contact cathode 5 is located at the other end of the GaN channel layer 2 and the AlGaN barrier layer 3 . The heat dissipation film 7 is located on the surface of the AlGaN barrier layer 3 and covers the ohmic contact anode 4 , and the...

Embodiment 3

[0063] See Figure 9 , Figure 9 A schematic diagram of the structure of the fourth GaN planar Gunn diode based on the compound heat dissipation anode provided by the embodiment of the present invention, Figure 9 The GaN planar Gunn diode includes: AlGaN back barrier layer 1, GaN channel layer 2, AlGaN barrier layer 3, ohmic contact anode 4, ohmic contact cathode 5 and Schottky extension layer 6.

[0064] Wherein, the AlGaN barrier layer 3 is located on the GaN channel layer 2 . The ohmic contact anode 4 is located at one end of the surface of the AlGaN barrier layer 3 , and the ohmic contact cathode 5 is located at the other end of the surface of the AlGaN barrier layer 3 . The Schottky extension layer 6 is located on the surface of the AlGaN barrier layer 3 and covers the ohmic contact anode 4, and together with the ohmic contact anode 4 forms a composite heat dissipation anode to suppress the self-heating effect of the device. For the relevant features of the Schottky e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com