Photon radiation heat radiation structure

A heat dissipation structure and photon radiation technology, which is applied in the field of radiation heat dissipation, can solve problems such as increasing system complexity and increasing equipment manufacturing costs, and achieve the effects of lowering temperature, reducing energy consumption, and lowering equipment temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

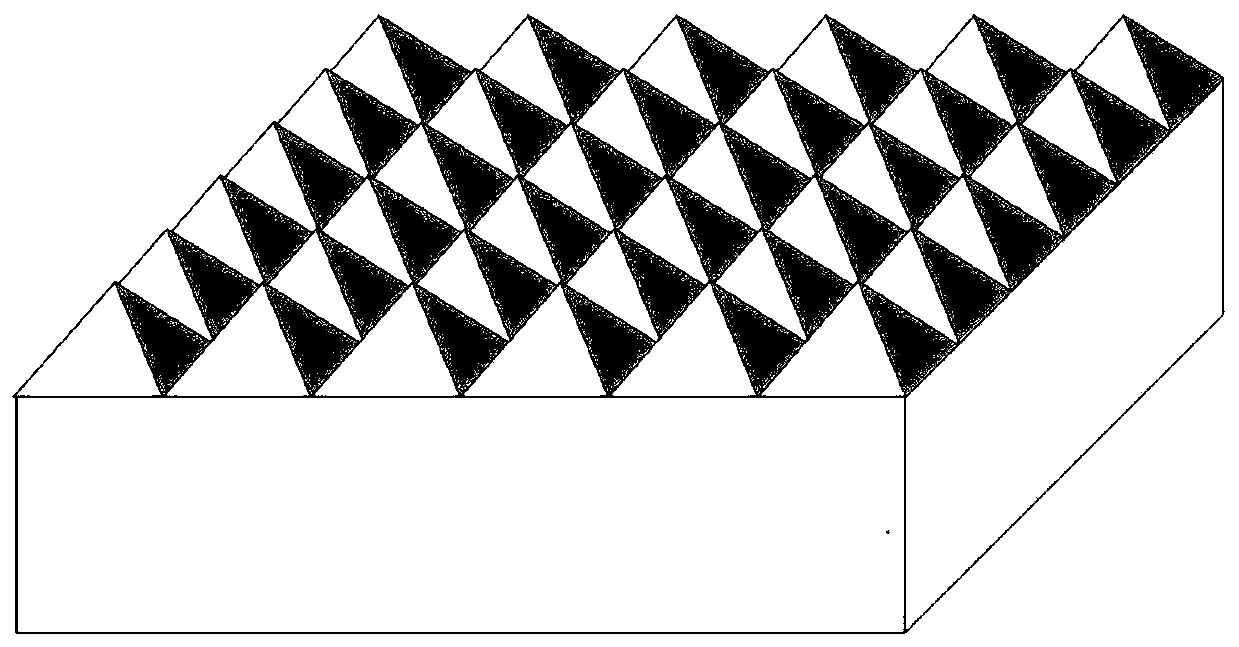

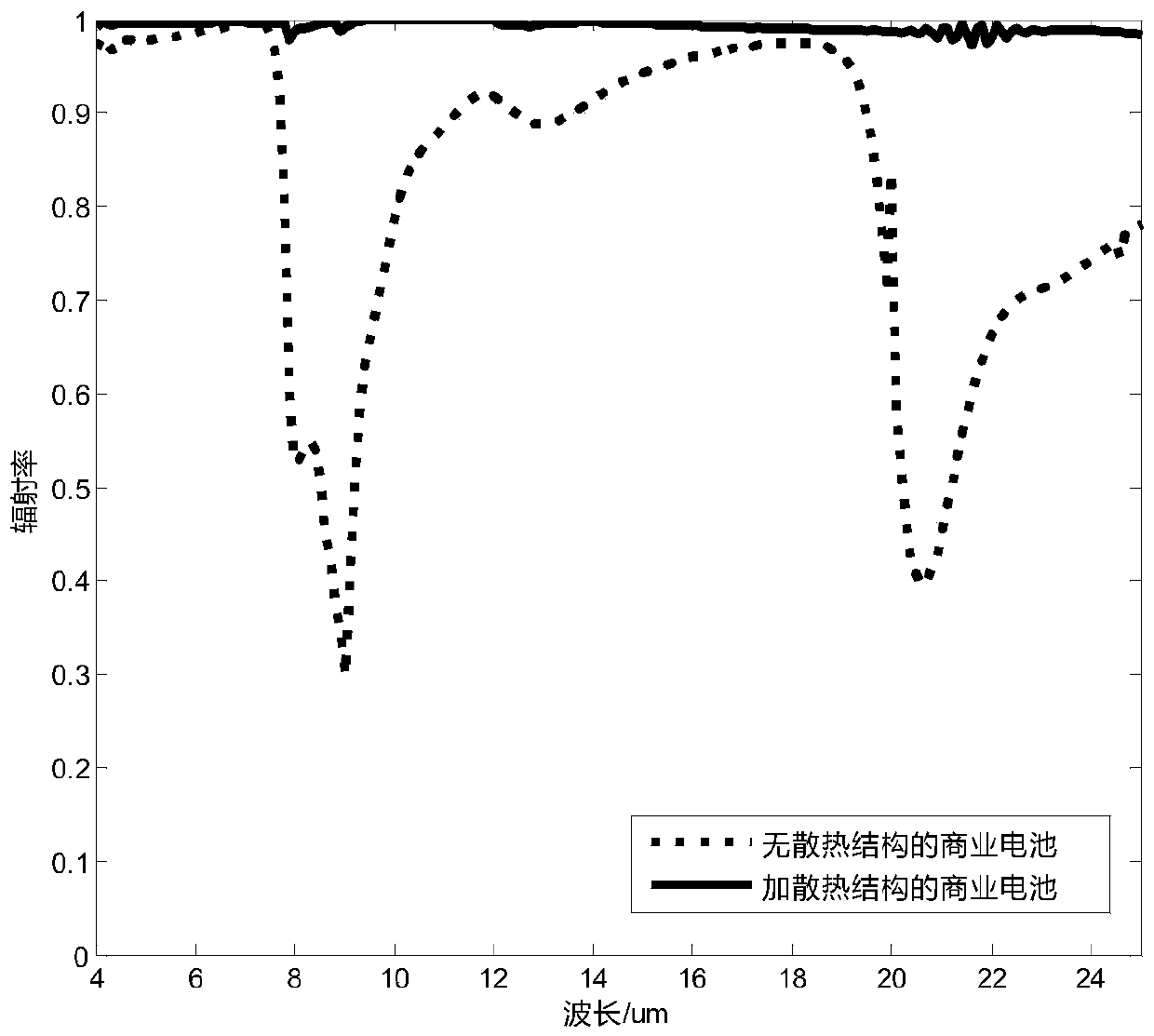

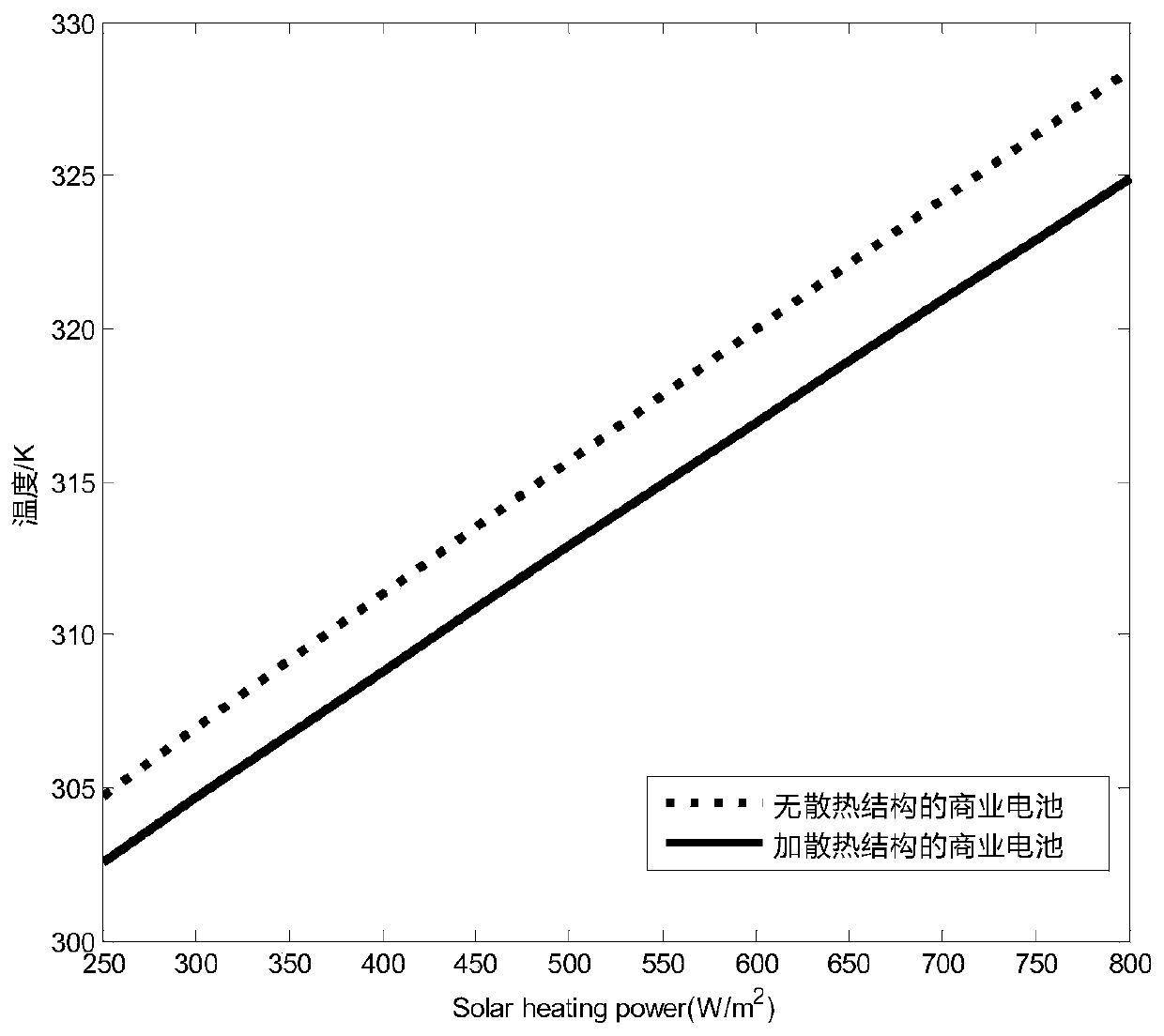

[0032] In this embodiment, the photon radiation heat dissipation structure that needs to be prepared has a period of 12um, and the height of the pyramid in the periodic unit is about 8.47um. The ratio of the pyramid structure to the unit period is 0.9. The material is silicon dioxide. The radiation heat dissipation structure is applied to traditional commercial solar cells.

[0033] The periodic pyramid structure is prepared on a single crystal silicon substrate: a layer of AZ6112 resist film is coated on the surface of the crystalline silicon with an oxide layer by spin coating, assembled on a mask, exposed by a photolithography machine, and passed Development realizes the transfer of the mask pattern to the resist film. Use BOE solution to etch the silicon oxide layer to realize the transfer of the mask pattern to the silicon oxide layer. Using silicon dioxide as a mask, an etching solution was prepared according to the ratio of deionized water: potassium hydroxide: isopropano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com