Light weight pyrolytic self-adaptive dimensional efficient heatproof material

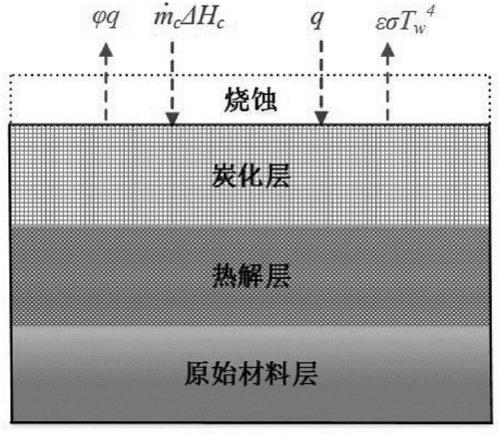

A heat-resistant material and self-adaptive technology, applied in the field of thermal protection systems, can solve the problems of not being able to meet the requirements of light weight and dimensional shape at the same time, changing the aerodynamic shape of the aircraft, affecting the target accuracy, etc. load, the effect of increasing the thermal radiation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

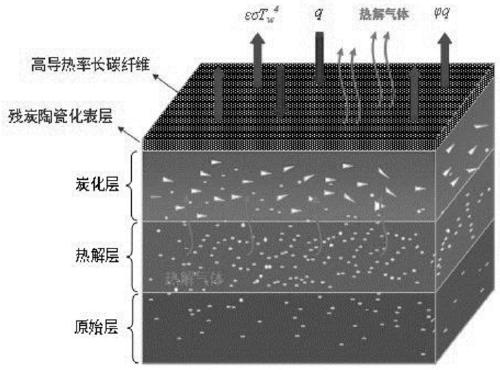

[0014] The invention uniformly mixes the treated chopped carbon fiber with silica sol and additives, and performs suction filtration to make a wet billet of silicide ceramic coated carbon fiber material, and then performs drying, molding and sintering process with the treated long carbon fiber with high thermal conductivity. A carbon fiber porous preform coated with silicide ceramics. The silicide ceramic-coated carbon fiber porous preform is immersed in yttrium sol, and after drying and sintering processes, the silicide, yttrium, and yttrium silicate ceramic-coated carbon fiber porous preform are produced.

[0015] In the present invention, inorganic elements such as boron, zirconium and silicon are introduced into the phenolic resin to prepare the inorganic substance blending modified phenolic resin. Through the characterization of the thermal stability of the modified resin and the characterization of the thermal radiation coefficient after high-temperature ceramization, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com