Double-contact structure of vacuum arc-extinguishing chamber

A technology of vacuum interrupter and double contacts, which is applied to high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve problems such as ablation, aging, and vacuum interrupter damage, and improve service life , Improve the effect of tolerance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

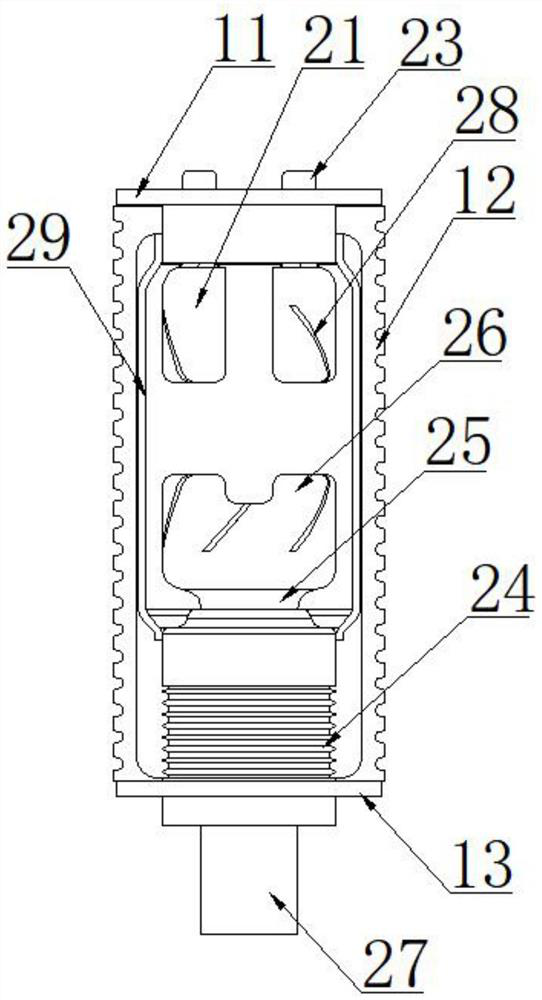

[0021] like figure 1 As shown, a double-contact structure of a vacuum interrupter includes a static end cover plate 11, a porcelain shell 12, a moving end cover plate 13, a static end cover plate 11, a porcelain shell 12, and a moving end cover plate from top to bottom. A closed vacuum chamber is formed between 13.

[0022] In the present invention, two static contacts 21 are provided separately below the static end cover 11 . In this embodiment, the two static contacts 21 are symmetrically arranged, and a top of the static contacts 21 is respectively provided with one extending to the static end cover. 11. The static guide rod 23 on the outer side, the top of the movable end cover plate 13 is provided with a bellows 24, the airtight vacuum chamber is provided with a movable contact 25, and the top of the movable contact 25 is provided with two protruding structures 26. The outlet structure 26 is symmetrically arranged, the two static contacts 21 are respectively arranged cor...

Embodiment 2

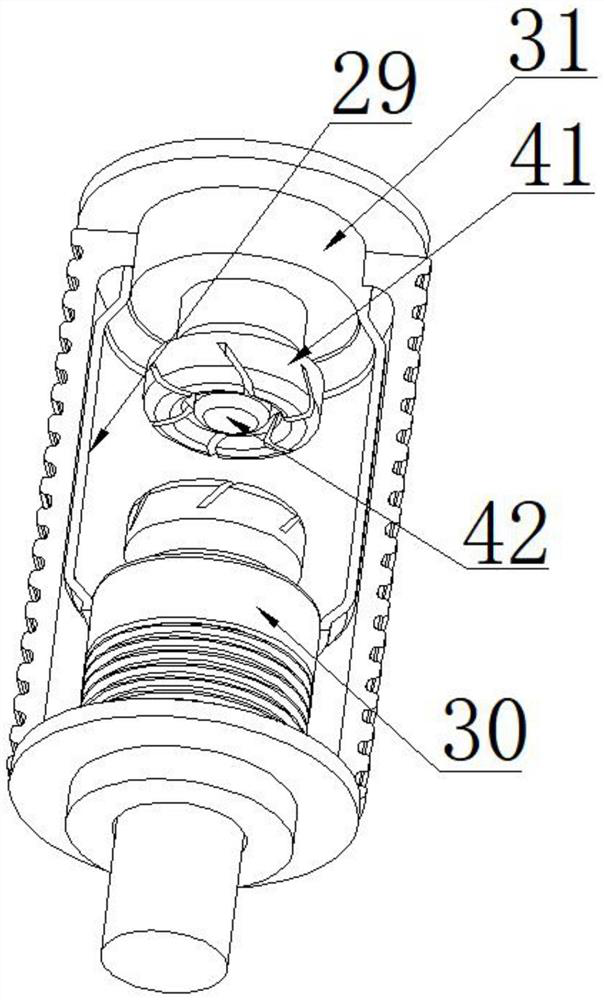

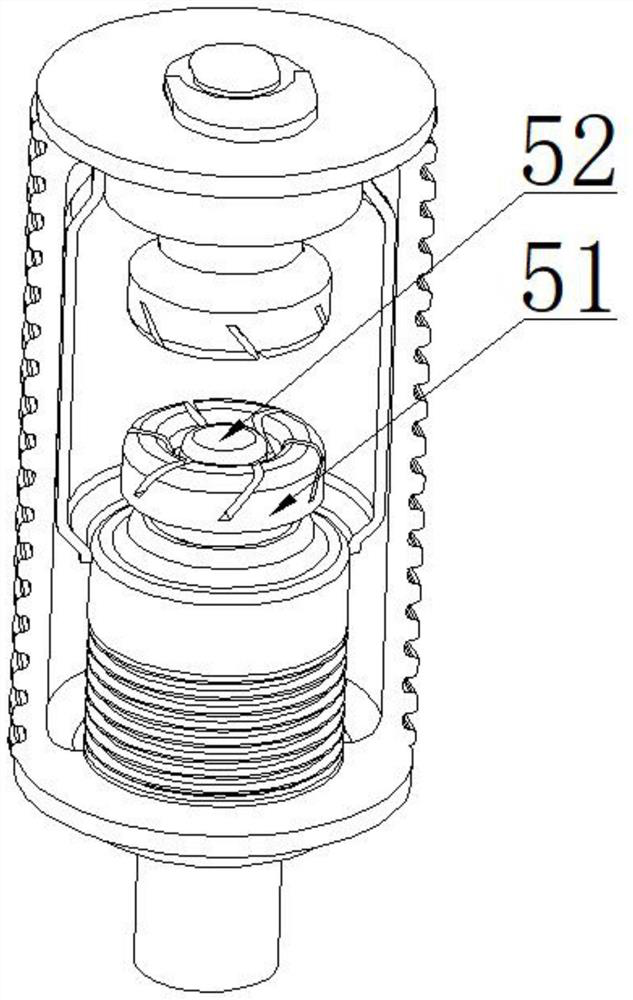

[0026] like figure 2 , 3 As shown, a double-contact structure of a vacuum interrupter includes a static end cover plate 11, a porcelain shell 12, a moving end cover plate 13, a static end cover plate 11, a porcelain shell 12, and a moving end cover plate from top to bottom. A closed vacuum chamber is formed between 13.

[0027] In the present invention, there are two static contacts 21 separated from the bottom of the static end cover 11 . In this embodiment, one of the static contacts is the first hollow cylinder 41 , and the other static contact is arranged on the first hollow cylinder 41 . The first solid cylinder 42 in the inner cavity of the cylinder; the top of the static contact 21 is respectively provided with a static guide rod 23 extending to the outside of the static end cover plate 11, and the top of the moving end cover plate 13 is provided with a bellows 24 to seal the vacuum A movable contact 25 is arranged in the chamber, and two protruding structures 26 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com