Metal rubber fabricated part and preparation thereof, and preparation method of metal rubber ring

A metal rubber, prefabricated technology, applied in mechanical equipment, shock absorbers, springs/shock absorbers, etc., can solve problems such as large structure size, large height size, cracking, etc., to achieve high weaving quality, tight weaving, large damping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The metal rubber prefabricated part comprises a core body and a cladding body, and its preparation comprises the following steps:

[0051] Wind and stretch 100g metal wire into a helical structure, the pitch of the helical structure is equal to the diameter, and set aside.

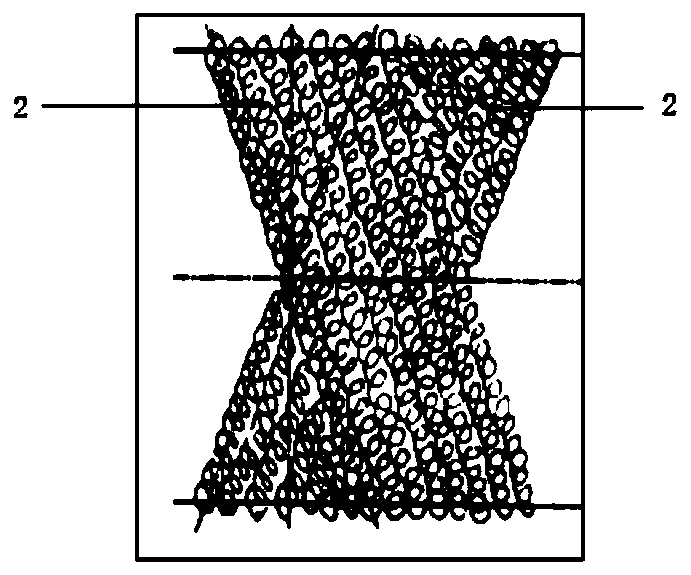

[0052] In a plane, a number of "○"-shaped structures are wound around the helical wire to fill the plane, forming a "○"-shaped braid (such as figure 1 As shown, the size of the helical coil is 20 times the outer diameter of the metal wire), and several layers of "○" type braiding layers are continuously formed on the "○" type braiding layer. Based on the area of the "○"-shaped structures, adjacent "○"-shaped structures overlap by 40% between adjacent layers. The metal wire used for the "○" type braid is 70g, and several layers of "○" type braids are formed as the core.

[0053] Wrapping the above-mentioned core body in the same oblique direction by a helical metal wire forms a first oblique brai...

Embodiment 2

[0055] The preparation of metal rubber ring comprises the steps:

[0056] Wind and stretch 100g metal wire into a helical structure, the pitch of the helical structure is equal to the diameter, and set aside.

[0057] In a plane, a number of "○"-shaped structures are wound around the helical wire to fill the plane, forming a "○"-shaped braid (such as figure 1 As shown, the size of the helical coil is 20 times the outer diameter of the metal wire), and several layers of "○" type braiding layers are continuously formed on the "○" type braiding layer. Based on the area of the "○"-shaped structures, adjacent "○"-shaped structures overlap by 40% between adjacent layers. The metal wire used for the "○" type braid is 70g, and several layers of "○" type braids are formed as the core.

[0058] Wrapping the above-mentioned core body in the same oblique direction by a helical metal wire forms a first oblique braiding layer, and wraps obliquely around the first oblique braiding layer ...

Embodiment 3

[0063] The preparation of metal rubber ring comprises the steps:

[0064] Wind and stretch 100g metal wire into a helical structure, the pitch of the helical structure is equal to the diameter, and set aside.

[0065] In a plane, a number of "○"-shaped structures are wound around the helical wire to fill the plane, forming a "○"-shaped braid (such as figure 1 As shown, the size of the helical coil is 20 times the outer diameter of the metal wire), and several layers of "○" type braiding layers are continuously formed on the "○" type braiding layer. Based on the area of the "○"-shaped structures, adjacent "○"-shaped structures overlap by 40% between adjacent layers. The metal wire used for the "○" type braid is 70g, and several layers of "○" type braids are formed as the core.

[0066] Wrapping the above-mentioned core body in the same oblique direction by a helical metal wire forms a first oblique braiding layer, and wraps obliquely around the first oblique braiding layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com