Anti-buckling low-frequency vibration isolation rubber support

A rubber bearing and anti-buckling technology, applied in the direction of earthquake resistance, building types, buildings, etc., can solve problems such as fatigue, reduce the comfort of adjacent civil engineering facilities, affect the normal use of vibration-sensitive instruments and equipment, and achieve low stiffness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

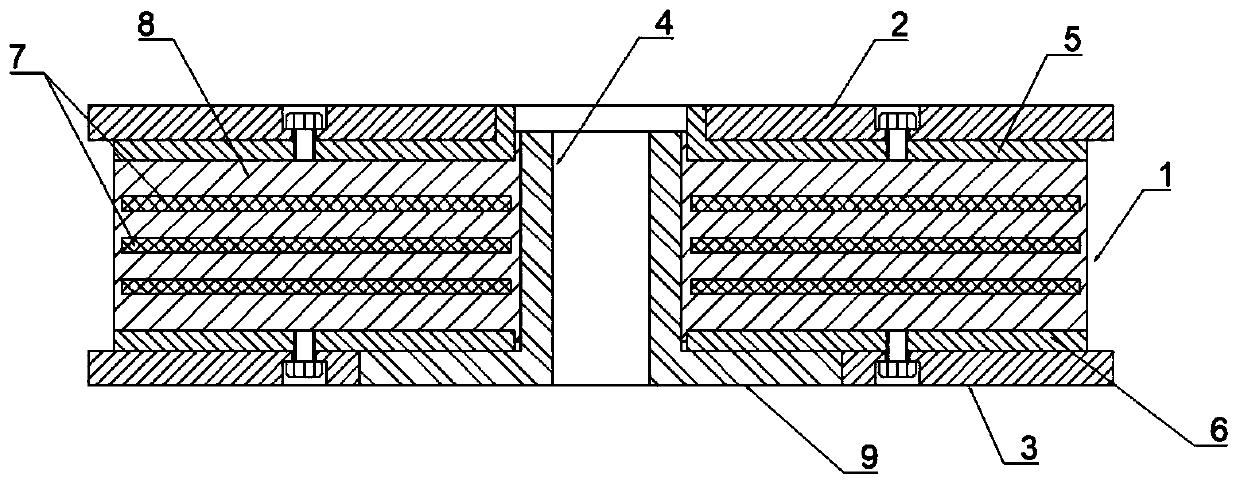

[0045] see Figure 1-Figure 16 , the anti-buckling low-frequency vibration-isolation rubber bearing of the present invention includes a rubber bearing body 1, an upper connecting steel plate 2 arranged at the upper end of the rubber bearing body 1, and a lower connection plate arranged at the lower end of the rubber bearing body 1. The steel plate 3 and the anti-seismic sleeve 4 arranged in the rubber bearing body 1, wherein the rubber bearing body 1 includes the upper sealing layer steel plate 5, the lower sealing layer steel plate 6, and the upper sealing layer steel plate 5 and the lower sealing layer steel plate The multi-layer laminated rubber 8 between the sealing steel plates 6, wherein the laminated rubber 8 and the inner steel plate 5 are connected into one body through high-temperature vulcanization bonding; an inner steel plate is arranged between two adjacent layers of laminated rubber 8 7. The anti-seismic sleeve 4 is vertically arranged in the rubber bearing body...

Embodiment 2

[0084] see Figure 17 The difference between this embodiment and Embodiment 1 is that the rubber layer 10 is a thin rubber ring, and the thin rubber ring is set on the anti-seismic sleeve 4 .

[0085] All the other structures are implemented with reference to Example 1.

Embodiment 3

[0087] see Figure 18 The difference between this embodiment and Embodiment 1 is that one of the multiple anti-seismic sleeves 4 vertically penetrates the upper connecting steel plate 2 sequentially from the axial center of the rubber bearing body 1 , the rubber bearing body 1 and the lower connecting steel plate 3, the rubber bearing body 1 is provided with a through hole at the position in contact with the shockproof casing 4, a rubber layer 10 is arranged in the through hole, and the rubber layer 10 is implemented with reference to the rubber layer 10 in Example 1.

[0088] And other anti-seismic sleeves 4 are distributed along the circumferential direction of the rubber bearing body 1, and vertically run through the upper connecting steel plate 2, the rubber bearing body 1 and the lower connecting steel plate 3 in sequence; A through hole is provided at the contact position of the anti-seismic sleeve 4 , and a rubber layer 10 is arranged in the through hole, and the rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com