Corrugated base paper moisture-proof process

A corrugated base paper and process technology, which is applied in the field of papermaking, can solve problems such as reduction of carton ring compression strength, quality accidents, and collapse of goods, and achieve the effects of reducing time waste, good water and moisture resistance, and improving the degree of gelatinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

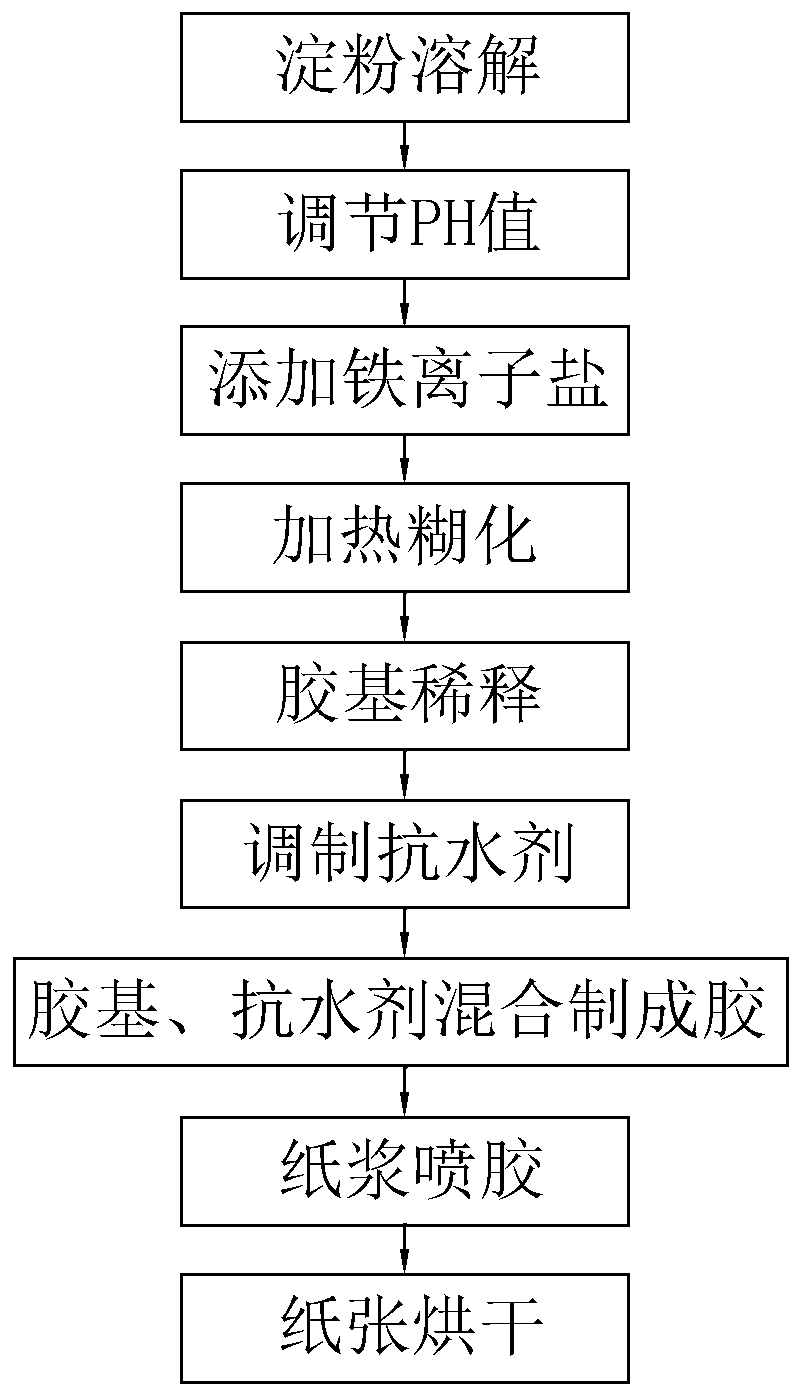

[0038] Such as figure 1 Shown, a kind of corrugated base paper moisture-proof process, comprises the following steps:

[0039] S1 To make the gum base, first mix the starch with warm water at a ratio of 1:1. During the process of dissolving the starch, you need to add the starch while stirring to obtain a starch suspension solution, and then add glacial acetic acid to the starch solution to adjust the pH value to After 6-7, add ferrous sulfate of 15% starch weight to the starch suspension, and fully mix and stir.

[0040] After adding ferrous sulfate, the starch solution needs to be gelatinized. The specific operation method is: use steam as the heat source, first heat the starch solution to 65°C at a heating rate of 5°C / min, and then heat the starch solution at a heating rate of 3°C / min. Heat the starch solution to 90°C, then heat the starch solution to 95°C at a heating rate of 2°C / min, and keep it warm for 15 minutes to fully gelatinize the starch and obtain a gum base.

[...

Embodiment 3

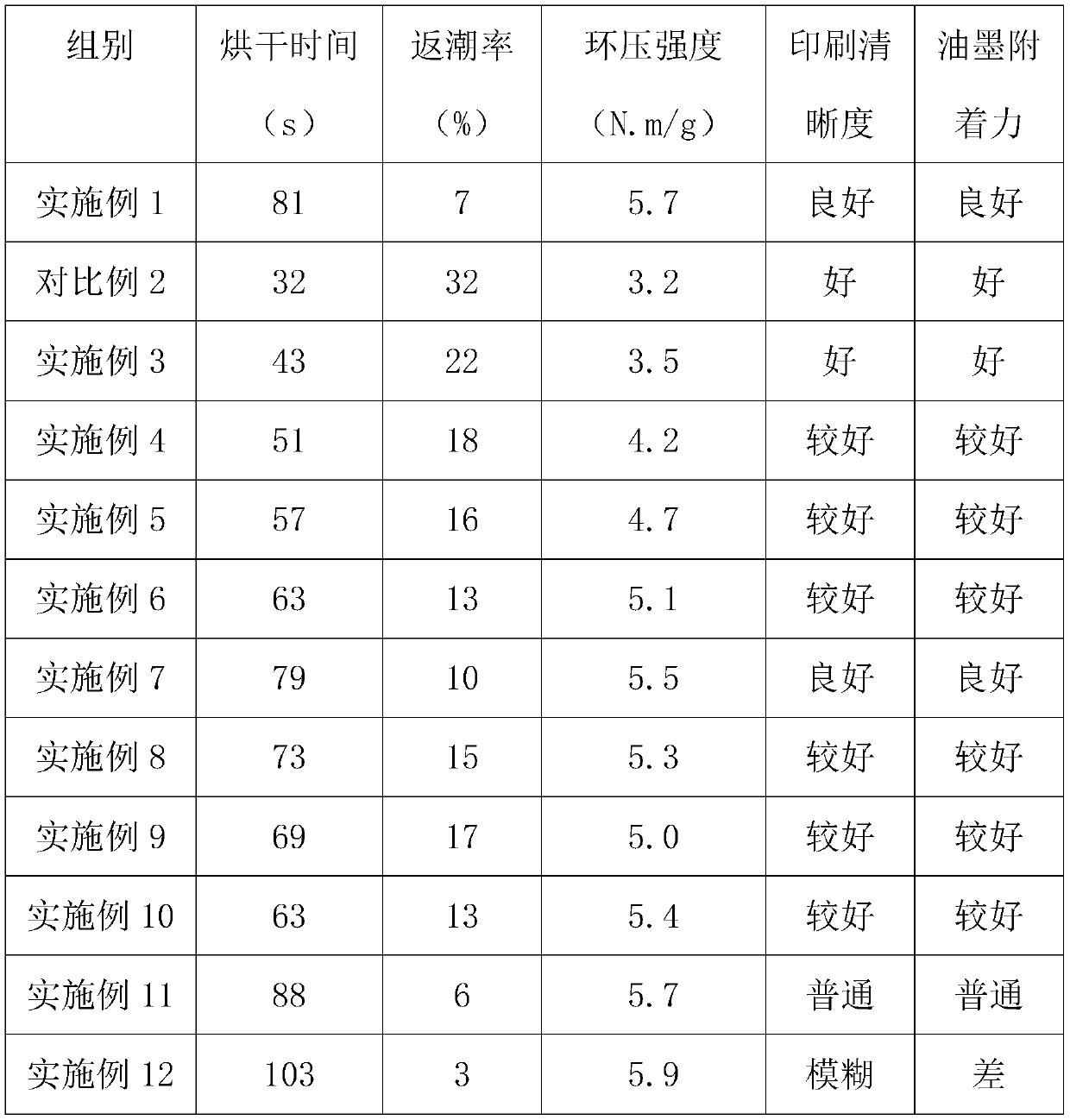

[0050] A moisture-proof process for corrugated base paper, only adding polyvinyl alcohol accounting for 1% of the total weight of the diluted rubber base as a water-resistant agent, and the rest of the process conditions and steps are exactly the same as in Example 1.

Embodiment 4

[0052] A moisture-proof process for corrugated base paper, only adding phenolic resin accounting for 0.8% of the total weight of the diluted rubber base as a water-resistant agent, and the rest of the process conditions and steps are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com