Deep hole nickel electroplating plating solution and preparation method thereof

A technology of deep hole electroplating and nickel plating, which is applied in the field of electroplating nickel, can solve the problems of insufficient demand for electroplating and deep plating, and achieve potential industrial application value, good corrosion resistance, and good brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

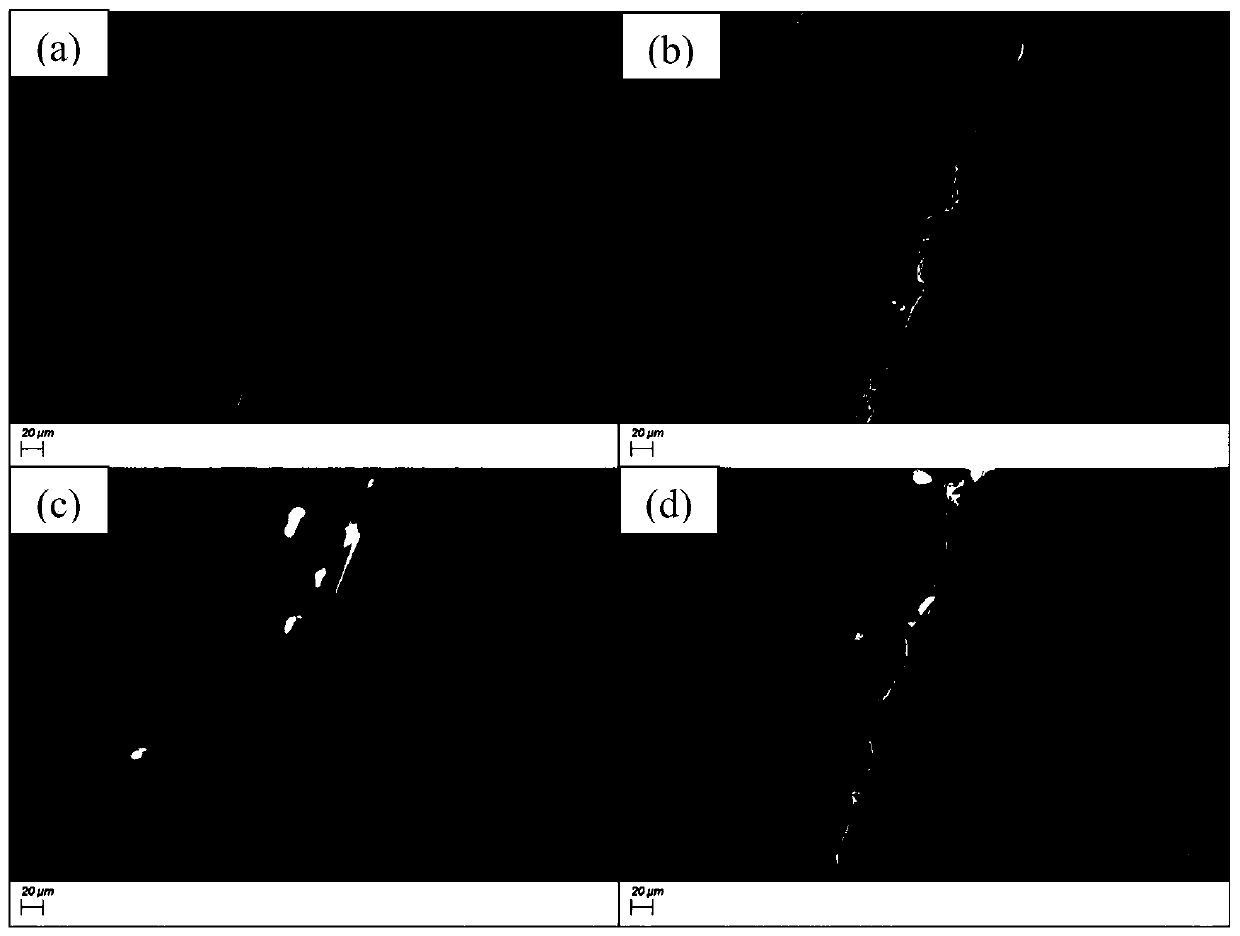

Image

Examples

preparation example Construction

[0049] The present invention also discloses a method for preparing the plating solution of the above-mentioned deep hole bright nickel plating, comprising the following steps:

[0050] Step 1, weighing various raw materials according to the concentration of each component in the deep hole electroplating nickel solution;

[0051] Step 2, dissolving nickel sulfate, nickel chloride, boric acid, sodium dodecylbenzenesulfonate with deionized water to obtain nickel sulfate basic solution;

[0052] Step 3. Dilute the hydroxypropyl displacing agent with deionized water, then add the diluted hydroxypropyl displacing agent to the nickel sulfate basic solution, mix and stir;

[0053] Step 4, add sodium citrate, stir well;

[0054] Step 5, add ammonium sulfate, fully stir;

[0055] Step 6, adding PS reagent, fully stirring to obtain deep hole electroplating nickel plating solution.

[0056] The preparation method of the invention can ensure that the obtained plating layer is bright and...

Embodiment 1

[0068] The content of each component is as shown in table 1 in the present embodiment announcement a kind of deep-hole electroplating nickel plating solution:

[0069] Contents of each component in the nickel bath for deep-hole electroplating in table 1

[0070]

[0071]

[0072] The present embodiment discloses a kind of preparation method of deep-hole electroplating nickel plating solution, specifically comprises the following steps:

[0073] Step 1. Add 800ml of deionized water to container A. While stirring, add 300g of nickel sulfate, 45g of nickel chloride, 35g of boric acid and 0.05g of sodium dodecylbenzenesulfonate, and stir until completely dissolved;

[0074] Step 2. Take 1ml of hydroxypropyl displacement agent with a volume fraction of 55vt%, dilute it 100 times with deionized water, take 2ml and add it to container A;

[0075] Step 3. Add 200ml of deionized water into container B, add 50g of sodium citrate and 5g of ammonium sulfate under stirring, and stir...

Embodiment 2

[0085] The content of each component is as shown in table 2 in the present embodiment announcement a kind of deep-hole electroplating nickel plating solution:

[0086] Contents of each component in the nickel bath for deep-hole electroplating in table 2

[0087]

[0088] Step 1. Add 800ml of deionized water to container A. While stirring, add 300g of nickel sulfate, 50g of nickel chloride, 50g of boric acid and 0.08g of sodium dodecylbenzenesulfonate, and stir until completely dissolved;

[0089] Step 2. Take 1ml of hydroxypropyl displacement agent with a volume fraction of 55vt%, dilute it 100 times with deionized water, take 20ml and add it to container A;

[0090] Step 3. Add 200ml of deionized water into container B, add 80g of sodium citrate and 20g of ammonium sulfate under stirring, and stir until fully dissolved;

[0091] Step 4. Pour the solution in container B into container A while stirring, and continue stirring for 30 minutes;

[0092] Step 5. Add 0.08 g of P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com