FeCrNiAlTi-series dual-phase high-entropy alloy and preparing method thereof

A high-entropy alloy and alloy technology, applied in the field of high-entropy alloys, can solve the problems of unrealistic production and application and high cost of high-entropy alloys, and achieve the effects of high strength and hardness, excellent performance, and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

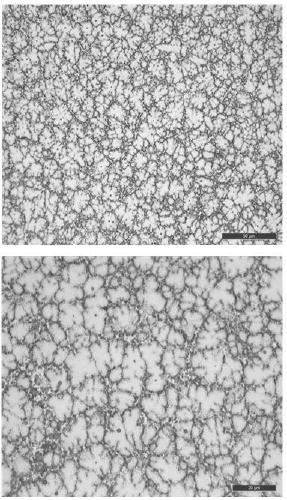

Image

Examples

Embodiment 1

[0033] This embodiment is a FeCrNiAlTi-based high-entropy alloy composed of five elements, Fe, Cr, Ni, Al, and Ti, and the atomic percentage ratio of Fe, Cr, Ni, Al, and Ti is 28.6667:28.6667:28.6667:7: .

[0034] The raw materials for preparing this alloy are pure Fe, pure Cr, pure Ni, pure Al and pure Ti. The mass of each element metal is shown in the table below:

[0035] Table 1 raw material ratio:

[0036]

[0037] The specific implementation process is as follows:

[0038] A preparation method of FeCrNiAlTi system high-entropy alloy, comprising the following steps:

[0039]Step 1. Pretreatment of raw materials: selecting pure Fe, pure Cr, pure Ni, pure Al and pure Ti with a purity greater than 99.9% for batching. The oxide skin on the metal surface needs to be polished off before batching. Put the polished raw materials into a beaker filled with absolute ethanol, and then put them into an ultrasonic cleaner for about 10 minutes to remove impurities and stains on ...

Embodiment 2

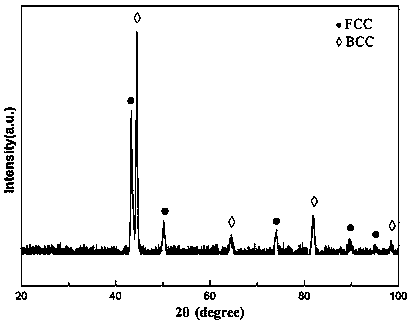

[0051] Example 2: Calculation (FeCrNi) 86 Al 7 Ti 7 Related parameters of high-entropy alloys, such as atomic size difference δ, mixing entropy S mix , Mixing enthalpy △ H mix , mixed melting point Tm, valence electron concentration VEC, electronegativity difference Δχ, parameter Ω are summarized in Table 2. The physical and chemical parameter criteria for forming high-entropy alloy solid solution are: δ≤6.6% and Ω≥1.1. (FeCrNi) 86 Al 7 Ti 7 δ=5.5171%, Ω=1.8357, so high-entropy alloy solid solution can be formed.

[0052] Table 2 Calculation table of relevant parameters of high-entropy alloy

[0053]

[0054] The calculation formulas of relevant parameters are as follows:

[0055]

[0056] Among them, C i — molar percentage of i component, ri — atomic radius of i component

[0057]

[0058] Among them,—the mixing enthalpy between i,j components, ri ,rj—the atomic radius of i,j components

[0059]

[0060] Among them, R—molar gas constant, R=8.3144J / (mo...

Embodiment 3

[0065] Example 3: Test Step 3 (FeCrNi) 86 Al 7 Ti 7 The instrument used for the micro-Vickers hardness is the MH-600 micro-hardness tester. Before the experiment, the samples cut by wire cutting were first mounted with a hot mounting machine, and then polished on 400, 600, 800, 1000, 1200, 1500 and 2000 mesh sandpaper in order until there were no scratches visible to the naked eye, and then polished It is polished on the machine, and no scratches can be observed under a 100x optical microscope. Generally, the measurement needs to be tested at 5-10 different positions, and the average value of the results is taken to ensure the accuracy of the test. The distance between every two positions should be greater than four times the length of the diagonal line, and a maximum value and a minimum value should be removed when calculating the average hardness value to reduce errors. The test uses a test force of 1000gN and loads for 15 seconds. The 10 measurements are summarized in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

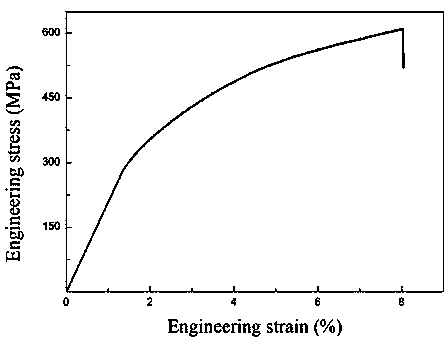

| Yield strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com