Processing method of aluminum flat ingot with ultra-high width-to-thickness ratio

A processing method and aluminum alloy technology, applied in metal processing equipment, equipment for feeding molten metal into molds, manufacturing tools, etc., can solve the problems of non-concentrated stress release of aluminum ingots, high scrap rate, and difficulties in casting and molding, etc. problems, achieve the effect of reducing the risk of cracks, improving market competitiveness, and shortening the crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

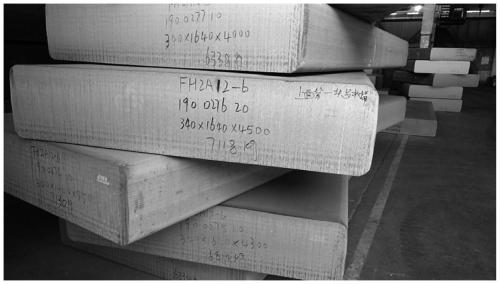

[0026] Example 1: Supply of 2A12 alloy to Southwest Aluminum (Group) Co., Ltd. on April 25, 2019, melting number 190 0271

[0027] Take the processing of aluminum alloy flat ingots in the flat ingot workshop of Chongqing Fenghe Aluminum Industry Co., Ltd. as an example. The processing method of ultra-high aspect ratio aluminum alloy flat ingot has the following steps:

[0028] A. 16558kg of raw materials (3467kg of original aluminum ingots, accounting for 20.94%, 12568kg of primary scrap, accounting for 75.90%; master alloy 526kg, accounting for 3.18%; because there is no secondary waste that meets the requirements on site, no secondary waste is put in ) Put into the smelting furnace for smelting, the smelting temperature is 736℃;

[0029] B. The flow channel of the outlet section of the aluminum liquid filter box and the flow channel of the splitter plate are sprayed with boron nitride paint;

[0030] C. Preheat the splitter plate and control the front end temperature of the splitte...

Embodiment 2

[0033] Example 2: Supply of 2A12 alloy to Southwest Aluminum (Group) Co., Ltd. on April 25, 2019, melting number 190 0272

[0034] Take the processing of aluminum alloy flat ingots in the flat ingot workshop of Chongqing Fenghe Aluminum Industry Co., Ltd. as an example. The processing method of ultra-high aspect ratio aluminum alloy flat ingot has the following steps:

[0035] A. 16050kg of raw materials (3468kg of raw aluminum ingots, accounting for 21.61%, 12054kg of primary scrap, accounting for 75.10%; master alloy 528kg, accounting for 3.29%; because there is no secondary waste that meets the requirements on site, no secondary waste is input ) Put into the smelting furnace for smelting, the smelting temperature is 744℃;

[0036] B. The flow channel of the outlet section of the aluminum liquid filter box and the flow channel of the splitter plate are sprayed with boron nitride paint;

[0037] C. Preheat the splitter plate and control the front end temperature of the splitter plat...

Embodiment 3

[0040] Example 3: Supply of 2A12 alloy to Southwest Aluminum (Group) Co., Ltd. on April 25, 2019, melting number 190 0273

[0041] Take the processing of aluminum alloy ingots in the flat ingot workshop of Chongqing Fenghe Aluminum Industry Co., Ltd. as an example.

[0042] A. 14984kg of raw materials (3013kg of original aluminum ingots, accounting for 20.11%, 8498.2kg of primary scrap, accounting for 56.72%; 476kg of master alloy, accounting for 3.18%; 2996.8kg of secondary scrap, accounting for 20%) into the melting furnace Smelting, the melting temperature is 743℃;

[0043] B. The flow channel of the outlet section of the aluminum liquid filter box and the flow channel of the splitter plate are sprayed with boron nitride paint;

[0044] C. Preheat the splitter plate and control the front end temperature of the splitter plate to be 695-705℃;

[0045] D. The molten aluminum flows out of the smelting furnace, and enters the inner cavity of the crystallizer through the aluminum liquid f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com