Isothermal normalizing heat treatment process

A normalizing heat treatment and process technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems that the cooling rate cannot be kept consistent, it is difficult to achieve uniform cooling of the gear shaft, and affect the machining and mechanical properties of the workpiece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

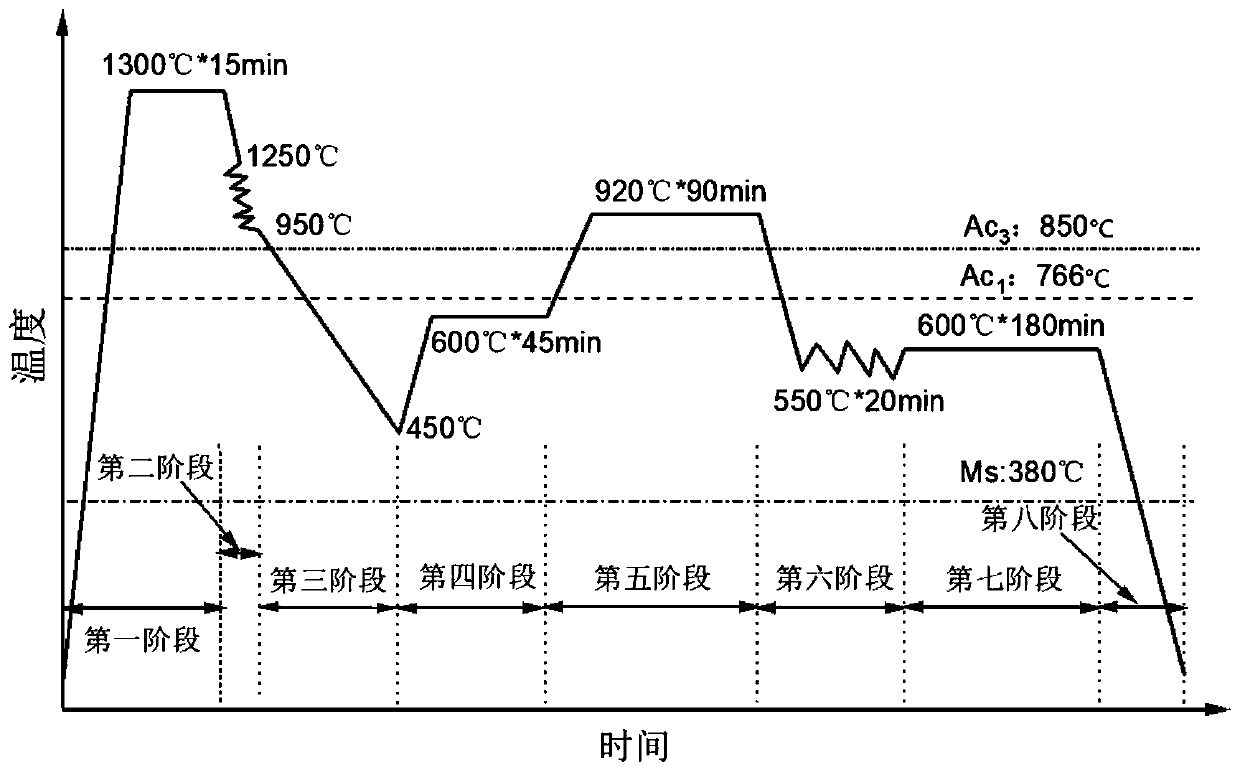

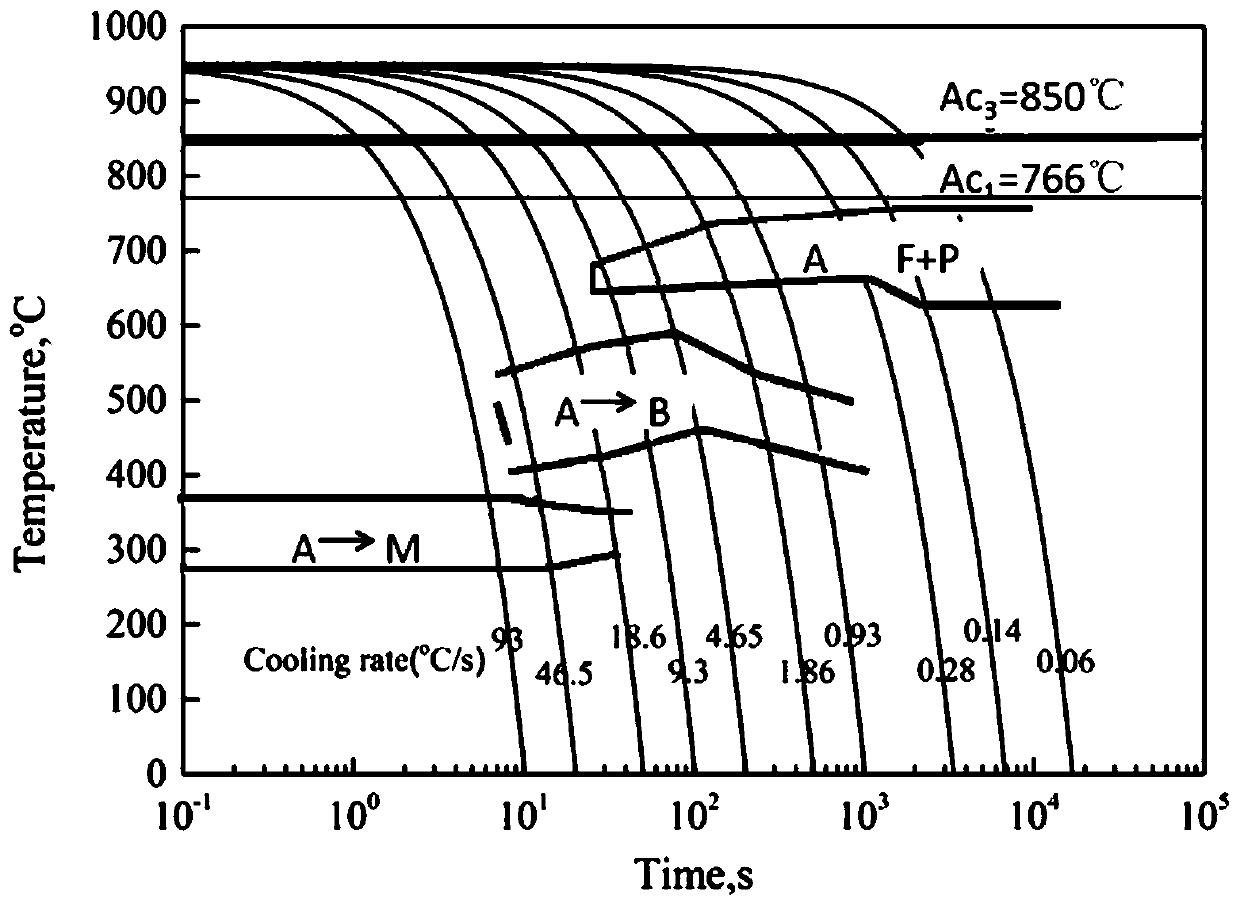

[0032] An isothermal normalizing process, which can transform the structure from austenite to uniform ferrite and pearlite after cooling for a certain period of time after the workpiece is austenitized. At the same time, it can rationally use the waste heat after rolling to save energy and Process costs, which include:

[0033] Step 1, heating the cylindrical billet in an induction heating furnace to transform the original annealed ferrite and pearlite structure into austenite;

[0034] Put the cylindrical blank of low-carbon and low-alloy carburizing steel in the induction heating furnace and heat it to 1100-1300°C, and determine the holding time according to the diameter of the workpiece, generally 10-30min, so that it can be transformed from the original annealed ferrite And the pearlite structure is transformed into austenite, so that the blank is austenitized and the composition is uniform, and the deformation resistance of the cylindrical blank is reduced, which is conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com