Production process of small low-alloy Q355B angle steel

A technology of Q355B and production process, which is applied in the field of production process of small low-alloy Q355B angle steel, can solve the problems such as toughness is difficult to guarantee, and achieve the effect of low requirements for rolling equipment and rolling process, excellent welding performance and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A titanium-strengthened low-alloy Q355B angle steel, its chemical composition and the mass fraction of each composition are shown in Table 1, and the rolling specification is ∠75×75×6. In the heating process, the continuous casting slab adopts cold charging, the heating temperature is 1230°C, the time in the furnace is 105min, and the temperature of the continuous casting slab is 1083°C; the rolling process, the rolling temperature is 1062°C, and the first stand The rolling mill reciprocated rolling for 4 passes, the second rolling mill reciprocated rolling for 5 passes, and the subsequent 5 stands The rolling mills each rolled one pass, the final rolling temperature was 923°C, the cooling rate of the cooling bed was 2.0°C / s, and the temperature of the lower cooling bed was 465°C. The mechanical properties of the titanium-strengthened low-alloy Q355B angle steel prepared in this example are shown in Table 2.

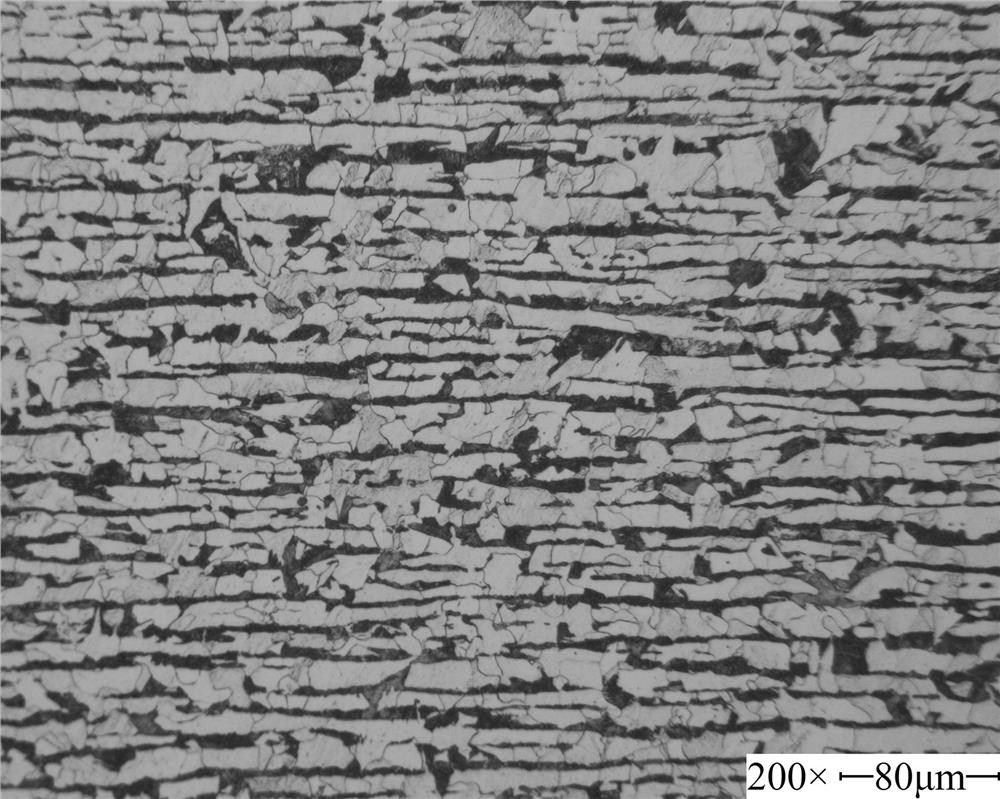

[0022] The metallographic photo of this embodiment Q355B ...

Embodiment 2

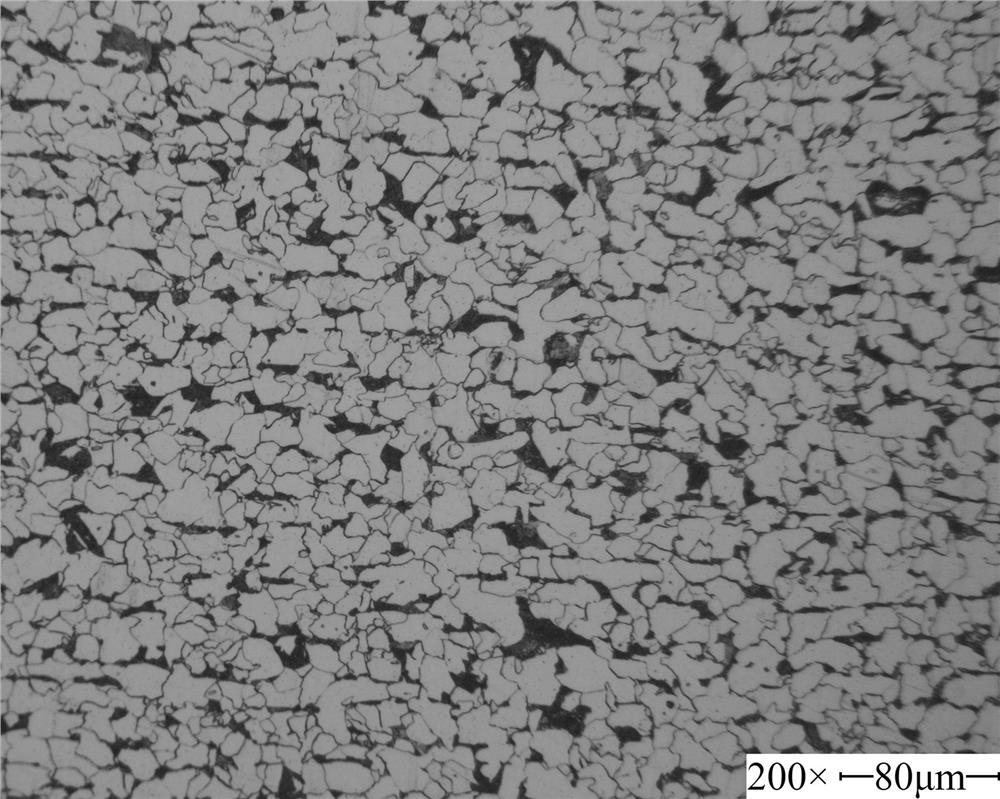

[0024] A titanium-strengthened low-alloy Q355B angle steel, its chemical composition and the mass fraction of each composition are shown in Table 1, and the rolling specification is ∠75×75×8. Continuous casting slab reheating process, continuous casting slab adopts cold charging, heating temperature 1210 ℃, furnace time 112min, continuous casting slab exit temperature 1053 ℃; rolling process, rolling start temperature 1038 ℃, the first stand 4 passes in the rolling mill, 5 passes in the second rolling mill, and 5 subsequent passes The rolling mills each rolled one pass, the final rolling temperature was 935°C, the cooling rate of the cooling bed was 1.8°C / s, and the temperature of the lower cooling bed was 489°C. The mechanical properties of the Q355B angle steel prepared in this example are shown in Table 2, and the metallographic structure is similar to Example 1.

Embodiment 3

[0026] A titanium-strengthened low-alloy Q355B angle steel, its chemical composition and the mass fraction of each composition are shown in Table 1, and the rolling specification is ∠75×75×10. Continuous casting slab reheating process, continuous casting slab adopts cold charging, heating temperature 1170°C, furnace time 121min, continuous casting slab exit temperature 1023°C; rolling process, rolling start temperature 1018°C, first stand 4 passes in the rolling mill, 5 passes in the second rolling mill, and 5 subsequent passes The rolling mills each rolled one pass, the final rolling temperature was 916°C, the cooling rate of the cooling bed was 1.6°C / s, and the temperature of the lower cooling bed was 521°C. The mechanical properties of the Q355B angle steel prepared in this example are shown in Table 2, and the metallographic structure is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com