Method for preparing herba epimedii low-glycoside components from herba epimedii

A technology of low glycoside and epimedium, which is applied in the field of compound extraction and preparation, can solve the problems of failing to ensure complete conversion of polyglycosides, destroying the structure of chemical components, unfavorable environmental protection by waste water, etc., and achieves strong safety and specificity, The effect of high catalytic activity and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

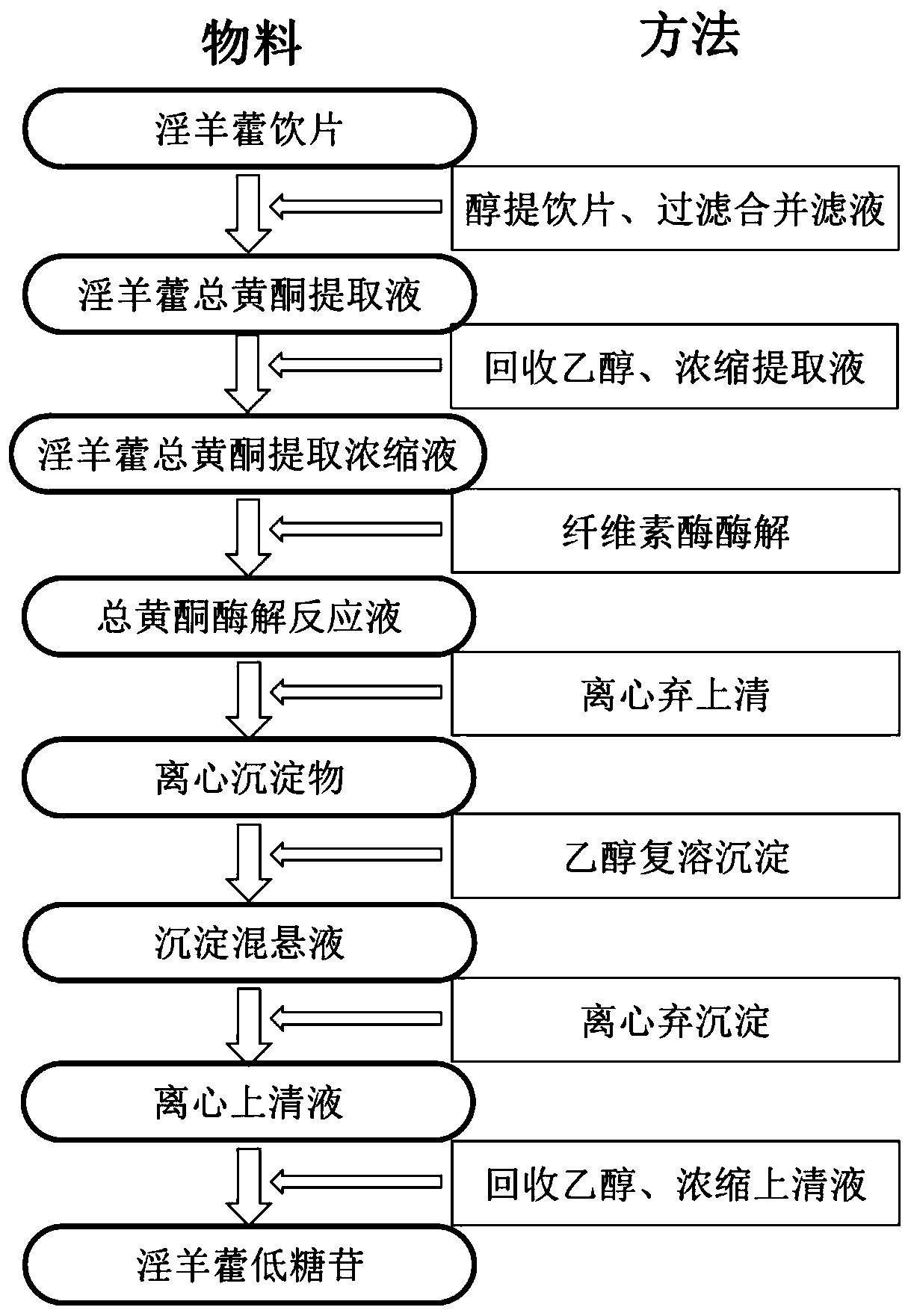

Method used

Image

Examples

Embodiment 1

[0029] (1) Take an appropriate amount of Epimedium decoction pieces, add 15 times the volume of 80% ethanol, heat and extract once, extract for 3 hours, filter and combine the filtrate, recover ethanol under reduced pressure at 50°C, and concentrate the extract to contain Epimedium per ml The quality of Herba Herba Herba Decoction Pieces was 0.1g to obtain the concentrated solution of Epimedium flavone polyglucoside component extract; Add cellulase to the extracted concentrated solution, stir evenly, and adjust the pH of the solution to 4.5, set the stirring speed to 100r / min, heat and react at 40°C for 48 hours, and obtain the enzymatic hydrolysis reaction solution, take an appropriate amount to detect Epimedin A and Epimedin B, epimedin C and icariin basically all disappear, reaching 99% enzymolysis conversion rate; (3) get the enzymolysis reaction liquid and be 10000r / min centrifugation 10min with the rotating speed, discard supernatant, collect precipitation, according to ...

Embodiment 2

[0031](1) Take an appropriate amount of Epimedium decoction pieces, add 25 times the volume of 40% ethanol, heat and extract once, extract for 2 hours, filter and combine the filtrate, recover ethanol under reduced pressure at 60°C, and concentrate the extract to contain Epimedium per ml The quality of Herba Herba Herba Decoction Pieces was 0.05g, and the concentrated solution of Epimedium flavone polyglucosides component was obtained; Add cellulase to the extracted concentrated solution, stir evenly, and adjust the pH of the solution to 6.5, set the stirring speed to 50r / min, heat and react at 50°C for 24 hours, and obtain the enzymatic hydrolysis reaction solution, take an appropriate amount to detect Epimedin A and Epimedin B, epimedin C and icariin basically all disappear, reaching 100% enzymolysis conversion rate; (3) get the enzymolysis reaction solution and be centrifuged at 8000r / min for 20min with a rotating speed, discard the supernatant, collect the precipitate, and ...

Embodiment 3

[0033] (1) Take an appropriate amount of Epimedium decoction pieces, add 20 times the volume of 50% ethanol, heat and extract twice, extract for 1.5 hours, filter and combine the filtrate, recover ethanol under reduced pressure at 55°C, and concentrate the extract until it contains perml The quality of Herba Herba Herba Decoction Pieces is 0.2g, and the concentrated solution of Epimedium flavone polyglucoside fraction is obtained; Add cellulase to the component extraction concentrate, stir evenly, adjust the pH of the solution to 5.5, set the stirring speed to 60r / min, heat and react at 40°C for 36h, and obtain the enzymatic hydrolysis reaction solution, take an appropriate amount to detect epimedin A, epimedin Ding B, epimedin C and icariin basically all disappeared, and the enzymolysis conversion rate reached 99%; (3) take the enzymolysis reaction solution and centrifuge it at a speed of 3000r / min for 40min, discard the supernatant, collect the precipitate, According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com