Clean utilization method of coal slime generated in coal mining process

A technology of mining process and coal slime, which is applied in the field of clean utilization of coal slime, can solve problems such as unsatisfactory utilization of coal slime, achieve good heat insulation effect, improve adaptability, and have wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for clean utilization of coal slime produced in a coal mining process, comprising the following steps:

[0026] S1, take by weight 80 parts of coal slime, 5 parts of brucite fiber, 1 part of borax, Sb 2 o 3 0.5 parts, 1 part of bis(2-ethylhexyl) phthalate;

[0027] S2, mixing and pulverizing the coal slime and borax weighed in S1 and passing through a 100-mesh sieve to obtain a mixture A;

[0028] S3, add the brucite fiber, Sb weighed in step 1 to the mixture A 2 o 3 And bis(2-ethylhexyl) phthalate, mixed uniformly to obtain mixture B;

[0029] S4, granulating the mixture B to obtain raw pellets with a particle size of 5 mm;

[0030] S5, pre-roasting the raw material balls at 400°C for 30 minutes in a nitrogen atmosphere, and then alternately roasting them twice at 800°C and 1000°C for 20 minutes each time after the pre-roasting is completed to obtain ceramsite.

Embodiment 2

[0032] A method for clean utilization of coal slime produced in a coal mining process, comprising the following steps:

[0033] S1, take by weight 90 parts of coal slime, 8 parts of brucite fiber, 2 parts of borax, Sb 2 o 3 1 part, 0.5 part of bis(2-ethylhexyl) phthalate;

[0034] S2, mixing and pulverizing the coal slime and borax weighed in S1 and passing through a 100-mesh sieve to obtain a mixture A;

[0035] S3, add the brucite fiber, Sb weighed in step 1 to the mixture A 2 o 3 And bis(2-ethylhexyl) phthalate, mixed uniformly to obtain mixture B;

[0036] S4, granulating the mixture B to obtain raw pellets with a particle size of 8mm;

[0037] S5, pre-roasting the raw meal balls at 450°C for 30 minutes in an argon atmosphere, and then alternately roasting them twice at 900°C and 1050°C for 25 minutes each time after the pre-roasting is completed to obtain ceramsite.

Embodiment 3

[0039] A method for clean utilization of coal slime produced in a coal mining process, comprising the following steps:

[0040] S1, take by weight 100 parts of coal slime, 10 parts of brucite fiber, 3 parts of borax, Sb 2 o 3 0.5 parts, 0.5 parts of bis(2-ethylhexyl) phthalate;

[0041] S2, mixing and pulverizing the coal slime and borax weighed in S1 and passing through a 100-mesh sieve to obtain a mixture A;

[0042] S3, add the brucite fiber, Sb weighed in step 1 to the mixture A 2 o 3 And bis(2-ethylhexyl) phthalate, mixed uniformly to obtain mixture B;

[0043] S4, granulating the mixture B to obtain raw pellets with a particle size of 10 mm;

[0044] S5, pre-roasting the raw meal balls at 500°C for 30 minutes in a nitrogen atmosphere, and then alternately roasting them twice at 1000°C and 1100°C, each time for 30 minutes, to obtain ceramsite.

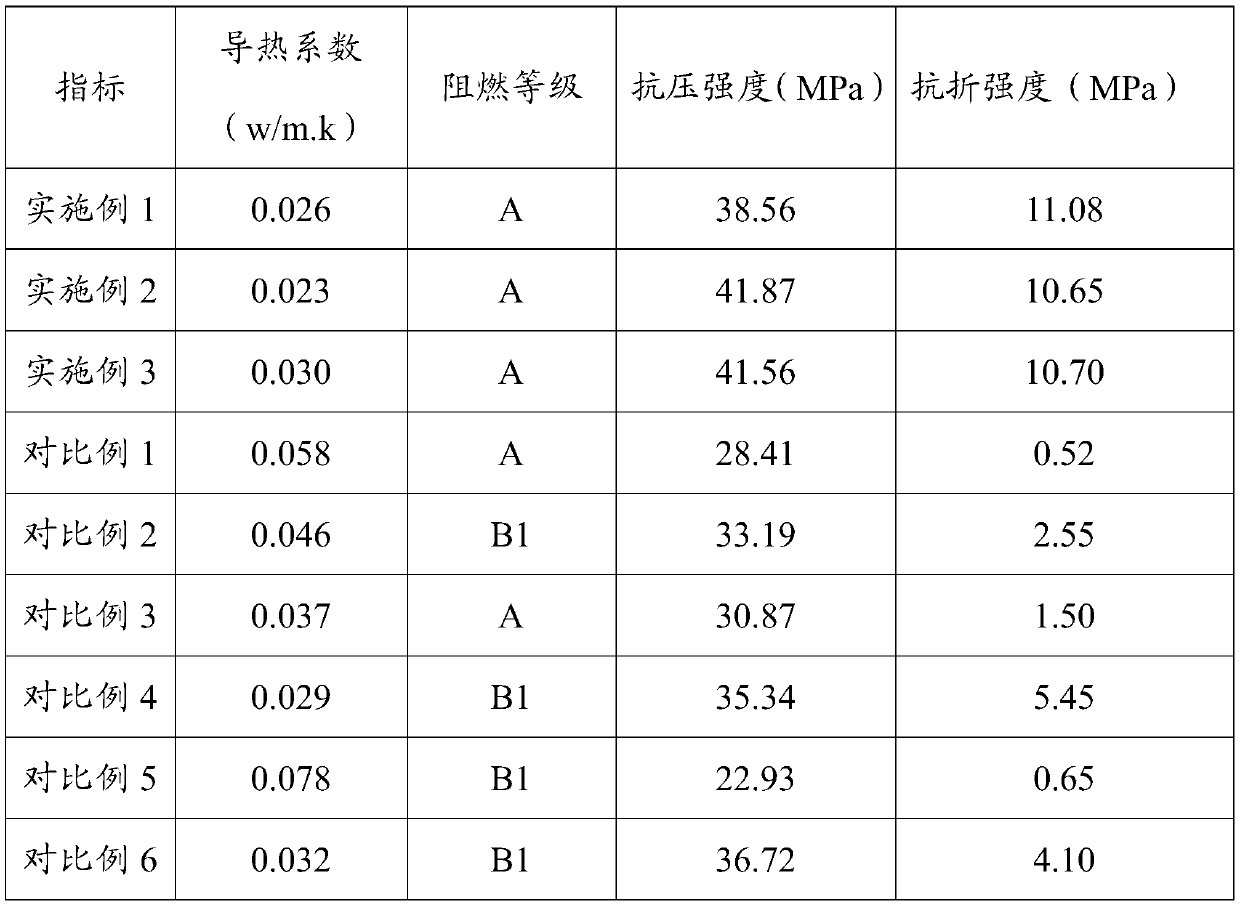

[0045] In order to further illustrate the effects of the present invention, the present invention also provides comparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com